In January 2024, we explored the tech landscape ahead of maintenance teams. It was a bold call to action. Take the Tech Leap, embrace the technologies that were already shaping operations elsewhere—before being left behind. With AI buzzing across industries and digital platforms promising smarter work, we asked maintenance teams to stop watching from the sidelines and begin experimenting, adapting, and upgrading.

We painted a roadmap filled with promise: Let Maintenance take a leap to Tech in 2024. We explained what does the tech leap look like in:

- Predictive maintenance powered by AI,

- IoT sensors constantly monitoring asset health,

- We also discussed the rise of AR/VR, 3D printing of spare parts, cybersecurity protocols, and the human-centric design of tools.

- Digital twins simulating performance before failures occur,

- And data-driven decision-making supported by machine learning.

But here we are—18 months later. Has maintenance truly taken the Tech Leap? Did these emerging technologies actually get adopted, and if so, where? Were some ideas overhyped or undercooked? And which ones delivered real value on the ground?

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

What Really Reached Maintenance Teams’ Hands? — The 2025 Reality

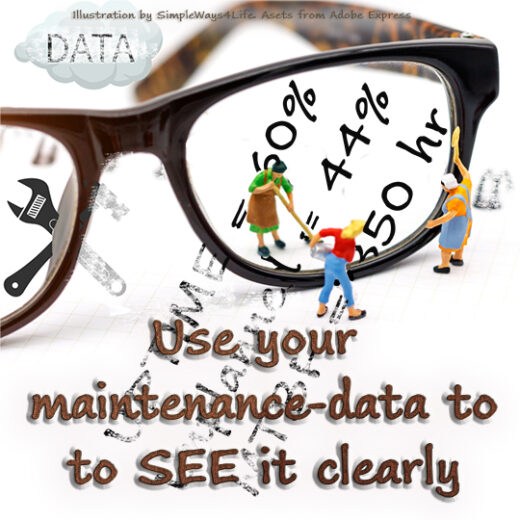

In early 2024, we outlined a strategic path: understand the tech landscape, then gradually embrace its tools. But understanding alone was never enough. What really matters is what made it into the hands of maintenance teams, on factory floors and in real-world routines.

So what truly arrived?

AI: From Buzz to Basics

AI did land—just not always as planned. Instead of fully autonomous failure prediction, many teams found value in AI-lite features built into existing tools. For example, CMMS platforms like UpKeep, Fiix, and Limble started integrating AI to suggest task intervals or flag anomalies from logs. AI wasn’t always visible, but it showed up in smarter defaults and better recommendations. Even the simplest Apps now can build AI within their logic. Have a look to this simple data recording DIY app: SW Asset Maintenance App. It will tell you based on temp and Vibration recording and inspector comments what initial actions need to be taken. The full version will be soon available for you.

from 24 FEb to 01Mar:

Predictive Maintenance Tools

IoT-based condition monitoring became more common, but mostly in industries already familiar with SCADA or vibration sensors. Affordable kits like SensrTrx, KCF Technologies, and SKF Pulse helped smaller teams try condition-based triggers. However, adoption remained cautious due to data overload or integration hurdles.

The Tech leap in 3D Printing of Spare Parts & Tools

So let’s jump to what is reported as real in 2024 and 2025 for car companies and heavy industries using 3D printing. This was mainly for parts and spare parts, as well as Danieli’s scanning-for-parts services. These examples illustrate that 3D printing is moving from prototyping to full-scale spare and production parts. And the industry scale is ranging from automotive to heavy equipment and shipbuilding.

In Heavy Industries

Project at Maghreb Steel (Morocco, 2025): Danieli Service took the tech leap and used its advanced on-site 3D scanning technology to reverse-engineer and replace an upcoiler mandrel (5 m long) at a hot strip mill. Their scanning system gave extremely accurate measurements—detecting a 4-mm deformation, allowing their engineers to redesign and manufacture a functionally improved replica with no need for shipping the part or disrupting operations. Danieli provides this scanning paired with 3D modeling directly at customer sites, offering faster, more precise spare part replacement and reverse engineering for heavy industry without equipment modifications or long logistics delays

HD Hyundai Heavy Industries (Shipbuilding, 2024-2025): In May 2024, ABS and HD Hyundai Heavy Industries launched a project for 3D printing spare parts onboard ships, pioneering onboard additive manufacturing to ensure rapid replacement of complex parts at sea and in remote areas

Wilhelmsen & thyssenkrupp (Marine Sector): These companies disrupt marine/offshore supply chains by providing a 3D print-on-demand spare parts service for ships and offshore platforms, significantly lowering costs, delivery times, and environmental impact by printing parts at or near dock

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

In automotive Industry:

- 3D printing enables on-demand production of custom and replacement car parts, reducing the need for physical inventory. For example, ABcar Oldtimers in Poland used 3D printers to fabricate steering wheel components for a Ferrari 599 and dashboard elements for a vintage Mercedes Benz, speeding up restoration work and lowering costs compared to traditional manufacturing.

- Automakers such as BMW, Toyota, and Ford have increasingly adopted 3D printing for lightweight, complex components, including for current production vehicles and electric/hybrid models. This includes prototyping and manufacturing low-volume or customized parts like battery enclosures, heat management parts, and suspension components.

- Forbes reports that Companies like Divergent Technologies collaborate with high-end automotive brands (Mercedes-Benz, Aston Martin, McLaren) to produce 3D printed suspension and structural parts, showcasing the use of additive manufacturing to create advanced, lightweight components for performance vehicles.

- The global automotive 3D printing market grew from around $3.36 billion in 2024 to over $4 billion in 2025, reflecting wider industry uptake of 3D printing for tooling, prototyping, and production of spare and end-use parts.

- 3D printing reduces manufacturing costs by eliminating molds and dies, speeding design iterations for spare parts, and enabling customized solutions especially useful for classic cars and low-volume replacement parts.

Ready to transform your mindset? Click and Get your copy > Now For Sale on Simpleways.life & Amazon

In sum, in 2024-2025 the automotive industry is actively using 3D printing for spare parts production, including in restoration, prototyping, and selective low-volume manufacturing of complex components. This trend is supported by notable case examples and market growth data.

Finally to recap

Looking ahead, the Tech Leap around 2024-2025 marks a pivotal moment where AI-enhanced CMMS solutions and additive manufacturing converge to transform industrial maintenance and manufacturing. The vision emphasizes scaling AI capabilities and integrating digital twins with simpler cloud-based simulation tools to make these technologies accessible beyond high-investment sectors like aerospace and energy.

For automotive and heavy industry, this means further expansion of digitalized, AI-driven maintenance workflows coupled with widespread adoption of 3D printing for spare parts production, driving resilience, customization, and operational excellence in a more agile and sustainable industrial ecosystem. The Tech Leap’s impact is seen in accelerating digital transformation, fostering innovation, and lowering barriers to entry for advanced maintenance and manufacturing technologies.