Harnessing AI for maintenance is not about replacing human judgment. It’s about amplifying it. The more clearly we shape AI’s instructions, the more precisely it delivers answers that matter. Just as a skilled technician reads a schematic before touching a machine, a skilled maintenance manager crafts AI prompts that guide it toward safe, practical, and reliable advice. Here, the CREATE formula steps in — a proven project management tool reimagined for the maintenance field.

In maintenance, reliability is not a coincidence — it’s a creation. Every safe, well-functioning workplace is the result of intentional planning, sharp decision-making, and the courage to embrace new tools. Creativity is not just for design departments; it is the lifeblood of a maintenance leader’s ability to anticipate problems, design solutions, and deliver consistent results. And today, creativity meets a powerful ally: Artificial Intelligence.

from 24 FEb to 01Mar:

From Project Sites to Plant Floors: How CREATE Bridges the Gap

Projects shape industries. From new construction to major upgrades, they set the pace for technological and operational growth. Project managers rely on tested frameworks to keep scope, cost, and quality under control. Maintenance may not always have a ribbon-cutting ceremony, but it demands the same discipline.

By applying CREATE to maintenance tasks, we transfer the precision and foresight of project management into the daily upkeep of equipment, systems, and facilities. This is not theoretical. The same prompt structure that helps a PM manage a multi-million-dollar hospital build can help a maintenance manager design a flawless preventive maintenance schedule, plan a shutdown, or troubleshoot a high-risk equipment failure.

The best part? CREATE turns AI from a generic search tool into a trained assistant who understands your plant, your standards, and your safety culture.

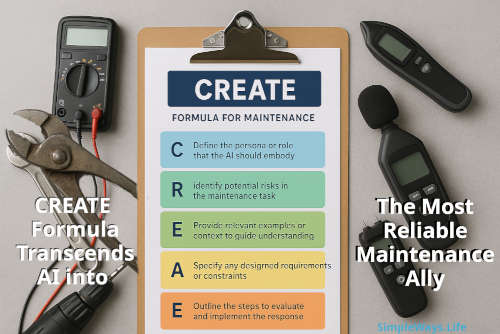

The CREATE Formula Explained for Maintenance Leaders

C – Character

Define who the AI should “be” in the conversation. This shapes the tone, depth, and relevance of its responses. For maintenance, you might say:

“You are a senior maintenance planner with 20 years’ experience in industrial equipment reliability and safety.”

This ensures the AI responds with expert-level thinking, not shallow, generic advice. learn more from this maintenance course with focus section on practical approaches for AI in Maintenance.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

R – Request

Clearly state the task you want completed. In maintenance:

“Create a step-by-step inspection checklist for the annual shutdown of the hydraulic press line.”

E – Examples

Provide references, previous cases, or specific context.

“Refer to last year’s shutdown checklist and include additional safety measures for the new hydraulic seals.”

A – Adjustments & Constraints

Specify safety rules, operational limits, or compliance requirements.

“Ensure all procedures meet ISO 45001 safety standards and can be performed within a 48-hour shutdown window.”

T – Types of Output

Decide on the structure and format.

“Deliver the checklist in a table format with columns for step, responsible person, and required tools.”

E – Evaluation & Steps

Tell AI how to validate the result.

“Verify that all steps minimize downtime and ensure no residual hydraulic pressure before seal removal.”

When you combine these six components, you create a complete, precise prompt that drives a much higher-quality AI response.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

A Real-World Example: a Factory Shutdown Plan

Let’s take a real maintenance scenario and run it through CREATE:

Character:

You are a certified maintenance manager specializing in large-scale industrial shutdowns. That’s part of what the AI agents are generally trained for or can train themselves for.

Request:

Create a comprehensive shutdown plan for the annual maintenance of a factory’s main conveyor system. You can add its details here to avoid generic answers or just pass the type and construction if it is universal

Examples:

Include steps from last year’s shutdown plus new procedures for recently installed belt tension sensors. These data can be available for the AI agent if integrated in your process a Cursor for software development. Otherwise it need to be attache to the prompt.

Adjustments & Constraints:

All work must comply with the plant’s lockout/tagout policy and complete within a 72-hour downtime window. These data can be available for the AI agent if integrated in your process a Cursor for software development. Otherwise it need to be attache to the prompt.

Types of Output:

Provide a step-by-step schedule in a Gantt chart format with assigned responsibilities.. That’s a universal format

Evaluation & Steps:

Confirm the plan includes all safety verifications, reduces risk of schedule overruns, and supports quick restart of production.

When this prompt runs through AI, you don’t just get a rough outline. You get a detailed, compliant, and practical plan that’s immediately useful in the real world — without extra guesswork or rework.

Ready to transform your mindset? Click and Get your copy > Now For Sale on Simpleways.life & Amazon

Why CREATE Works So Well for Maintenance

The strength of CREATE lies in its completeness. Instead of asking AI vague questions like “How do I shut down a conveyor?”, you guide it the way you would guide a new technician — with role clarity, task details, context, safety rules, formatting requirements, and quality checks.

This eliminates common failure points in AI-assisted work:

- Missing steps that cause rework

- Oversights that breach safety standards

- Generic answers that ignore site-specific needs

In maintenance, where safety and precision are non-negotiable, CREATE makes AI a partner you can trust, not a liability you must double-check.

Safety and Compliance: CREATE’s Built-In Guardrails

Many maintenance incidents start with unclear instructions or overlooked hazards. By embedding safety and compliance rules into the “Adjustments & Constraints” step, you create prompts that think safety-first.

Examples:

- “Follow OSHA standard 1910.147 for lockout/tagout.”

- “Ensure confined space entry procedures are included with atmospheric testing requirements.”

- “Minimize hot work in flammable storage zones.”

This way, AI isn’t just producing a task list — it’s producing a safe, regulatory-compliant task list that matches your facility’s standards.

How to Train Your Team to Use CREATE

The real power emerges when your whole team can write effective prompts. Imagine technicians and planners who can quickly ask AI:

- “Create a lubrication plan for all pumps in Zone 4, following OEM guidelines.”

- “Create a troubleshooting checklist for compressor vibration issues, including isolation steps.”

- “Create a parts-replacement schedule for the packaging line, optimizing for minimal downtime.”

By teaching everyone the six CREATE elements, you create a repeatable process that turns AI into a dependable, on-demand assistant for the whole department.

CREATE as a Culture, Not Just a Formula

When your maintenance department thinks in CREATE terms, every AI request has purpose and structure. Every checklist includes context. Every plan respects safety, timing, and quality. Over time, this mindset shift changes how your team approaches all problem-solving, not just AI interactions.

Why Creativity is the Foundation of Reliable Maintenance

In maintenance, reliability is something you create, not something you stumble upon. It’s the result of deliberate planning, smart decisions, and disciplined execution. Creativity in maintenance is not about artistic flair; it’s about innovative thinking when faced with constraints, hazards, and operational challenges. Every safe, well-functioning workplace is the result of someone imagining a better way to do the job — then making it happen.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Artificial Intelligence (AI) can turbocharge this process. But AI is only as good as the instructions you give it. Just like a technician can only follow the drawings you provide, AI can only act on the clarity of your prompt. The more clearly you shape AI’s instructions, the more effectively it becomes your ally. That’s where the CREATE formula — originally designed for project managers — becomes a powerful tool for maintenance leaders.

You no longer hope for reliability — you deliberately create it.

Final Thoughts: Creating Confidence with CREATE

In maintenance, confidence comes from knowing the job will be done right, safely, and on time. The CREATE formula gives AI the context and clarity it needs to help you achieve that standard consistently.

By bringing the precision of project management into the heartbeat of maintenance operations, you don’t just keep machines running — you create a safer, more reliable future for everyone who works alongside them.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment

Comments are closed.