Maintenance teams are always using machine learning (ML) to revolutionize their operations even if they don’t realize it. This comprehensive guide explores how machine learning is transforming maintenance practices, from basic systems to sophisticated predictive models.

Link between ML and AI

Artificial Intelligence (AI) has always been the overarching concept under which various technologies, including Machine Learning (ML), have developed. For a period, ML became the buzzword, capturing public attention and interest, especially with its commercial applications in ERP and Asset Management and many more applications that touches our life.

The complete content in a more refined way with exercises is now available as part of The Mindset Manifesto Book. You can Get it from here: Mindset Manifesto, A Blueprint for Life, Tech & work

However, as AI has evolved and gained prominence, it has once again become the focal point of discussion in the tech industry. This shift does not diminish the fact that AI has consistently served as the framework encompassing numerous algorithms designed to mimic human thinking, including rule-based intelligence, ML, and Generative Pretrained Transformers (GPTs). Each of these technologies plays a vital role in advancing our understanding and implementation of intelligent systems.

As algorithms and computer programs advanced, they began analyzing data to identify patterns and predict future events, marking the emergence of ML within the broader scope of AI. The latest phase, often highlighted as the pinnacle of AI, is the era of Generative Pretrained Transformers (GPT). These models have become a buzzword in today’s tech landscape, functioning as sophisticated assistants that respond to user prompts by applying advanced algorithms.

Table of Contents – This Article

- Introduction to Machine Learning in Maintenance

- Basic Maintenance Systems: The Foundation

- The Evolution to Machine Learning Models

- Understanding Machine Learning Algorithms for Maintenance

from 24 FEb to 01Mar:

Next Article will include:

- Practical Implementation: Building ML Models for Maintenance

- Case Studies: Machine Learning Success Stories in Maintenance

- Future Trends: The Road Ahead for ML in Maintenance

1. Introduction to Machine Learning in Maintenance

Machine learning has emerged as a game-changer in the field of maintenance, offering unprecedented capabilities to predict equipment failures, optimize maintenance schedules, and reduce downtime. By leveraging historical data and real-time inputs, machine learning models can identify patterns and anomalies that human operators might miss, leading to more efficient and cost-effective maintenance strategies.

The journey of machine learning began in the 1950s with early pioneers like Arthur Samuel, who coined the term “machine learning” in 1959. However, it wasn’t until the late 1990s and early 2000s that machine learning started to gain significant traction in various fields. The explosion of data availability and increased computing power in the 21st century has led to a renaissance in machine learning applications.

Today, machine learning touches nearly every aspect of our lives, often in ways we don’t even realize. From the personalized recommendations we receive on streaming platforms to the voice assistants on our smartphones, machine learning algorithms are constantly at work. In the field of maintenance, machine learning has been particularly transformative. It’s being used in industries ranging from manufacturing and energy to transportation and healthcare, helping to predict equipment failures, optimize maintenance schedules, and extend the lifespan of critical assets.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

For instance, in the automotive industry, machine learning algorithms analyze data from various sensors in modern vehicles to predict when components are likely to fail, allowing for proactive maintenance. [1]

In the energy sector, wind turbine operators use machine learning to optimize maintenance schedules based on weather patterns and equipment performance data [2]. These applications not only save costs but also improve safety and reliability across various industries.

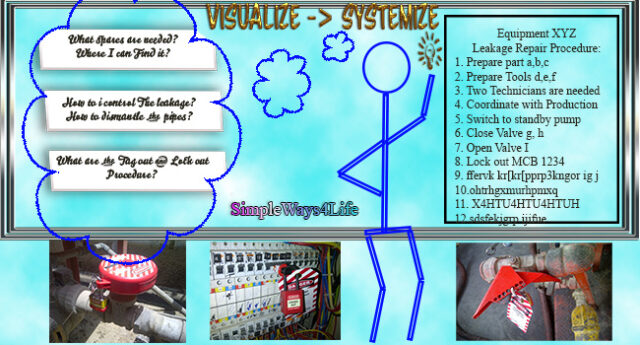

2. The story started from Basic Maintenance Systems

Before diving into the complexities of machine learning, it’s essential to understand the basic maintenance systems. These systems, often available as built in-house, free or freemium cloud-based solutions, serve as the starting point for many maintenance teams. If you have a sophisticated ERP or Asset Management system so most probably you’ve been using ML all along. However, currently same functions were labeled as AI which is the overarching concept under which various technologies, including Machine Learning (ML), have developed.

Key Features of Basic Maintenance Systems:

- Digital Checklists: Replace paper-based processes with digital forms.

- Rule-Based Alerts: Simple if-then logic to flag issues (e.g., if temperature > threshold, alert maintenance).

- Data Aggregation: Collect and store maintenance data over time.

- Basic Reporting: Generate simple reports on maintenance activities and equipment status.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

While these systems provide a significant upgrade from manual processes, they lack the predictive power of machine learning models. However, they play a crucial role in data collection, which is the foundation for more advanced machine learning applications.

3. Introducing Machine Learning Models

As maintenance teams accumulate data through basic systems, they pave the way for more sophisticated analysis using machine learning. This evolution marks a shift from reactive to predictive maintenance strategies.

The Machine Learning Advantage:

- Pattern Recognition: ML models can identify complex patterns in equipment behavior that simple rule-based systems might miss.

- Predictive Capabilities: Forecast potential failures before they occur, allowing for proactive maintenance.

- Continuous Learning: ML models improve over time as they process more data, adapting to changing equipment conditions.

This evolution doesn’t happen overnight. It typically involves a gradual process of data collection, model development, and integration with existing maintenance processes. As organizations become more comfortable with data-driven decision making, they can start to leverage more advanced ML techniques to further optimize their maintenance strategies.

LOWEST-PRICE-24F-01M

4. Understanding Machine Learning Algorithms for Maintenance – With Examples

Machine learning encompasses a variety of algorithms, each suited to different types of maintenance challenges. Let’s explore some key algorithms used in maintenance applications:

Linear Regression

Linear regression is one of the simplest yet powerful machine learning algorithms used in maintenance prediction. It models the relationship between a dependent variable (e.g., equipment lifespan) and one or more independent variables (e.g., operating hours, temperature).

In a maintenance context, linear regression could be used to predict how long a piece of equipment will last based on its usage patterns. For example, a factory might use linear regression to predict the lifespan of a motor based on its operating hours and average load. There are many factors affecting motor life expectancy as in this article: Factors In Motor Life Expectancy. If you measure those factors and then train the model on how they affect the motor life span, the ML model will be able to predict the motor lifespan. This allows maintenance teams to schedule replacements before failures occur.

Logistic Regression

While linear regression predicts continuous values, logistic regression is used for binary classification problems, such as predicting whether a piece of equipment will fail within a certain timeframe.

In a real-world scenario, logistic regression could be used to predict battery health, and prescribe maintenance actions for drone’s battery. The evolution of drones happened rapidly, as they have moved from gadgets and hobbies to tools for search, and rescue operations and its usage was extended to agriculture where drones can monitor crops and soil health,

Predictive maintenance, powered by machine learning models, presents an innovative solution to address the limitations of drone battery maintenance. “Predictive Maintenance on Drone Batteries Failure Using Machine Learning” is a study is to design and implement ML models suitable for drone batteries, predict battery health, and

prescribe maintenance actions. This allows drone owners or fleet managers to replace batteries proactively, avoiding unexpected breakdowns.

from 24 FEb to 01Mar:

Decision Trees and Random Forests

Decision trees and their ensemble counterpart, random forests, are excellent for capturing complex, non-linear relationships in maintenance data. They can handle both numerical and categorical data, making them versatile for various maintenance scenarios. “A solution is based on ML and deep learning (DL) techniques such as decision tree, random forest and deep neural network (DNN) to predict the different types of faults in these industrial components. This will help the maintenance team to repair or replace the components before the faults happen.” from: Predictive Maintenance in Industrial Machinery using Machine Learning

Imagine a manufacturing plant using a random forest model to predict machine failures. The model might consider factors like vibration levels, temperature, production speed, and maintenance history. Each decision tree in the forest might focus on different aspects of the data, and the combined wisdom of all trees provides a robust prediction of when a machine is likely to fail.

Neural Networks and Deep Learning

Neural networks, especially deep learning models, have shown remarkable success in handling complex, high-dimensional data. In maintenance, they can be used for tasks like anomaly detection in sensor data or predicting remaining useful life of equipment.

A practical application could be in aircraft maintenance, where deep learning models analyze data from hundreds of sensors to predict potential issues before they cause problems. “Under the current circumstances, deep learning is a critical application for the predictive maintenance of aircraft engines. There is ongoing demand in the aviation sector to increase operating efficiency, lower costs, and improve safety. Deep learning-enabled predictive maintenance presents a strong answer to these problems. ” Application of Deep Learning in Predictive Maintenance. Also, ” with an Airbus A380 having up to 25,000 sensors. This increase in data has driven greater use of data-driven PdM, that is to build and train PdM algorithms using data rather than domain experience. ” Predictive maintenance analytics and implementation

These models can detect subtle patterns that might indicate impending failure. Ultimately allowing for maintenance to be scheduled during planned downtime rather than causing unexpected delays.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

In Conclusion, ML Transforming Maintenance

In conclusion, this article has explored the transformative role of machine learning (ML) in maintenance practices across various industries. We began with an introduction to the foundational concepts of machine learning in maintenance, examining how traditional maintenance systems have evolved into sophisticated ML models. By understanding different machine learning algorithms—such as linear regression, logistic regression, deep learning, and random forests—we highlighted their applications in predicting failures of critical components like gearboxes, rotating equipment, and batteries, and high-stakes environments such as aviation.

As we look ahead to the next article, we will delve into Practical Implementation: Building ML Models for Maintenance, where we will provide actionable insights and methodologies for developing these models. Additionally, we will present Case Studies: Machine Learning Success Stories in Maintenance, showcasing real-world applications that demonstrate the effectiveness of ML in predictive maintenance. Finally, we will discuss Future Trends: The Road Ahead for ML in Maintenance, including emerging technologies and methodologies that promise to further enhance maintenance strategies.

Stay tuned for examples and code snippets that will guide you through the practical aspects of implementing machine learning models in maintenance. This crucial for ensuring that you are well-equipped to leverage these powerful tools in your operations.

References:

- Machine Learning Approaches for In-Vehicle Failure Prognosis in Automobiles, Volume 12, Number 1, January-March 2024, VFAST Transactions on Software Engineering

- Optimizing wind energy systems using machine learning. Volume 4, Issue 3, P.386-397, December 2023, Computer Science & IT Research Journal

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store