The target behind any of those tools to check maintainability is to make the maintenance tasks safer and easier. Consequently, it will take less time, less manpower and will be done correctly. When we say that the task is clear to the maintenance team, it mean they know exactly what to do without confusion. Confusion arises from missing information, wrong information, or ambiguity. If the part can be installed in different ways and causes no problem, that’s good. Otherwise, in case one of the possible installation ways would cause a problem, maintainability here means to eliminate this possibility.

That’s like when installing the positive and negative terminals of a battery. If reversing them would cause no problem, so it is an issue that can be ignored. Otherwise, if some electronics might fail due to this, the least action is to change the terminals and plugs sizes between positive an negative and to give them bold clear red and black colors. That’s maintainability in the sense of eliminating the source of mistakes.

More Questions to investigate Maintainability in all steps of the maintenance process

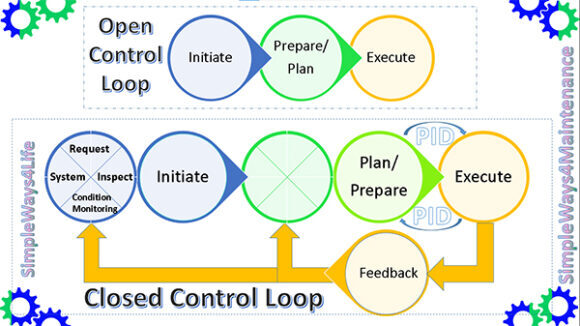

The previous article has demonstrated the first 33 questions to ask yourself and your team while preparing and executing maintenance. The target behind all this analysis of maintainability is to ensure that maintenance is clear and easy. When maintenance is clear and easy, maintenance direct and indirect costs will drop dramatically. As we explained last time; You don’t need to look for maintainability somewhere outside the maintenance activities themselves.

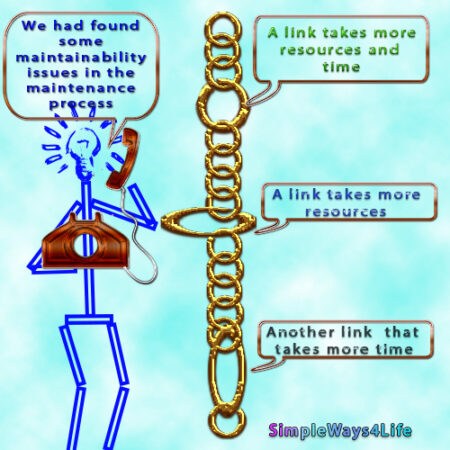

So every part of your maintenance process should be available and easily to reach or to do. Steps of the maintenance process are like the links of the chain. When they are not homogenous the chain would look ugly and perform badly

The maintenance activity includes:

- Detection of the need for maintenance

- Equipment stoppage time till it return back to operation (That’s an envelope for many activities)

- Parts or consumables used during maintenance

- Manpower whether as number or as hours

- Tools

- supporting equipment

- Documents

- Indications or marking

We had covered the first 2 points in the previous article and now we shall introduce the right questions to check the maintainability of remaining parts of the process.

3. Maintainability indications from spare parts and consumables

Not all maintenance activities include parts replacement or consumables replenishment. Relighting some bolts, cleaning, condition inspection and many other activities do not need parts to be replaced. When parts and consumables are needed, the following set of questions will help you figure out if it is clear and easy to do this task:

- How do you identify the needed parts?

- Are you certain that all parts needed are prepared?

- Is there a chance to prepare a wrong part?

- Are the parts prepared ready to be used or do they need some assembly or parameterization?

- What if you didn’t find the part in the stock list?

- Why you didn’t find?

- How fast can you order it?

- Is there a replacement?

- Did you think of the parts that can replace each other from before?

- Is there special instructions for the installation?

- How far your team is concrete about it?

- Is there are possibility of wrong installation? Why?

- What happens to the removed parts or fluids?

- How much time does it take to clear the wastes from the maintenance process?

- Who will do the cleaning task?

- Is there a clear dumping place for each type of wastes?

- Can those wastes be on resale?

4. Sufficient manpower, the critical balance

This part is somehow confusing. Usually manpower whether number or hours are a target of continuous control and cutting. It is like a perception that this the point where all the cost is wasted. Many studies came out to clarify that too many people needlessly present may cause problems and unrest. Even though that’s not far from truth, there is another valid view point to question the issue:

- How did the number of maintainers came up in the first place?

- Did you ever tried to question the time set for the task after the original plan?

- Do you consider rest, preparation and closing of the job in that time plan?

Now to check maintainability from the point of view of the manpower, we need to go through those questions:

- How do you know that the team assigned for the job is skilled enough to do it?

- Is the location of doing the job safe?

- Does the space available for doing the job allow more than one person to work together?

- Does the time and quality of the job vary between teams?

- If a single team member is doing the task, does adding another team member can reduce the time?

- On the other hand, if you assign more than one team members for the task,

- What does each one do?

- i.e. what are the responsibilities of each one? Can they divide the job between them?

- If next time one of them is unavailable, can his team mate do the job of the absent one?

- Are all the assigned members equally skilled?

- Providing additional tools can it reduce the manpower number or time on the job?

Those questions do not only help you improve maintainability. Actually they provide you with a clear understanding of the pros and cons of the size of your team. Moreover, you can easily restructure your team based on business expansion or shrink.

5. The role of tools as an indication and a support for maintainability

After thinking of the team, we should think of the tools they use. The tools doesn’t necessarily mean torque wrenches or screwdrivers. There are the software and the digital measuring tools beside the papers and manually-set tools.

- Do they know how to use those tools?

- Can they get the tools easily or reach additional ones during working?

- Where are the tools stored?

- Are the tools neatly stored, arranged and continually checked for readiness and availability?

- In case the tool needs some settings, can they do it?

- What is the probability that a maintenance task stops because the team brought a wrong tool to the site? Why this happened?

- Is there available out there in the market other or better set of tools that can help the team work faster and without mistakes?

6. Supporting Equipment

What we mean by supporting equipment is the equipment that extends the human ability. The dilemma is whether this supporting equipment takes less time and is safer or vice versa.

The main capabilities that we need to extend are not limited to the physical strength so you exert less physical effort using this support. Actually, those support equipment help to extend the audibility, visibility and precise sense of heat and vibration. Improving those senses are equally important to the physical strength.

- How heavy are the parts your team handle? Whether parts to replace, to take out for repair or covers to remove before starting their job.

- Is it safe to handle and support those parts the way they are doing it now?

- Can they propose a better way for doing this job safely and easily?

- When there is a confusion about increased vibration, Do they have the tools and standards to take the right decision at the right time?

- How to sense a hot part? After color change? When they smell an overheated grease or see smoke ?

- If the tools are provided, can they use it? The question of ability here invokes their technical ability and how safe it is to do this measurement while equipment is in operation?

- Introducing a digital tool to record the daily inspections, will it expedite the data recording, analysis and decision making? Will it create a burden on the team?

- An automatic calibrated torque wrench, how it can facilitate the performance?

7. Documentations, where to check maintainability in the everyday documents?

The original supplied equipment documentations can be considered as one of the vital assets. The maintenance system with activities and processes derives from those manuals and team experience is an equally important asset. The third and most vital asset is your team that would use those 2 previous assets.

So the documentation should be available easily whether I’m paper or digital copies. Then, the team need to have the ability to read it. So ask your team:

- Do they know the documents needed as part of each activity?

- How they reach it?

- What do they understand?

- Where they return the feedback?

- Is there some information they look for but can’t find except verbally from other team members?

8. Marking

You can consider this one as an add-on to the core elements in the maintenance process but its benefits to the maintainability makes it a valuable one.

Think of marking as the marks on the tightened bolts to know if they get loosen. Then expand this marking to marking the alarm and trip limits on gauges. Then question the availability of basic marking of any equipment or its individual parts using names and numbers:

- Are the equipment clearly labelled so there is no confusion when:

- A work request is generated

- A team member isolate the machine

- Record the feedback

- To record the cost of the consumed spares

- To record the cost of the consumed spares

- Are the internal parts of the equipment clearly labelled so the targeted sensor is easily detected?

- Is the electrical wiring numbered in a way that when some wires are disconnected they can be returned correctly?

- Is there a link between equipment numbering or labels in the shop floor and numbering in the schematics, P&I or detailed assembly drawings?

- If we can track problems to their root causes, how many times the confusion between labels, numbering or marks created a problem?

In conclusion,

The 55 Questions presented in this article together with the 33 ones in the previous one generates a survey of 88 Questions that would map the real maintainability status of the assets. Some of them might not be applicable. Some others might be needed for specific equipment not in general. When we got involved for some time in a career, we might be biased that what is general from our point of view is perceived same way by others. The target behind any of those tools to check maintainability is to make the maintenance tasks safer and easier. Consequently, it will take less time, less manpower and will be done correctly.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store