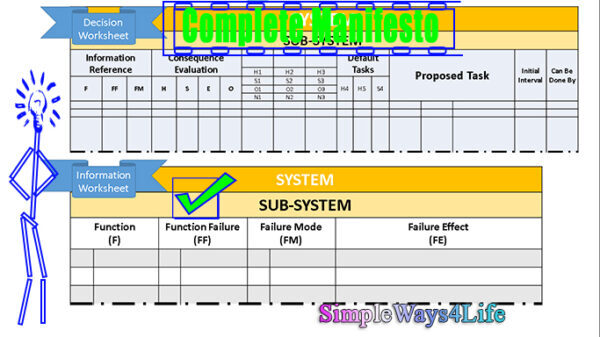

We shall demonstrate the main jargons used in the decision making sheet of the RCM (Reliability-Centered Maintenance). Those expressions are important to understand the process of applying the RCM. As explained in the last chat: 5-Reliability made easy – RCM Jargons, the RCM analysis ends up in 2 fundamental sheets: The Information Worksheet and The Decision Worksheet. During our path for making Reliability easy to understand and apply we need to have a North Star. The North Star guides you during your trip. Read More about it here: Where your compass points?. RCM processes North-Star are the decisions we are going to take about the existing maintenance tasks. Moreover, the decisions about the the maintenance tasks we are going to add or remove from our maintenance program to make it more efficient.

What is so far collected in the Information Worksheet?

- System & Sub-System divisions of our equipment

- Function i.e. how the equipment works and what is expected from it to do. Whether they are primary or Secondary Functions

- Function Failure i.e. its inability to fulfil totally or partially one of the primary or secondary functions

- Failure Mode. A list of all the possible causes of this failure

- Failure Effect. An essay like detailed description of what happens when this failure mode occurs.

Decision Worksheet:

Information reference F,FF,FM

F stands for Function number 1 to n, based on your facility size. The code of this function number is in the small column to the left of the function description on the Information Worksheet.

FF stands for Function Failure it is coded A to Z. Similar to the F Function, The code of this function number is in the small column to the left of the Function Failure description on the Information Worksheet. . It is a list of Failures for each Function or sub Function.

FM is 1 to n Failure Causes for each FF or Function Failure.

You end up in Something like this after mapping the Information Worksheet to the Decision Worksheet ->

| F | FF | FM | |

| 1 | A | 1 | |

| 2 | |||

| B | 1 | ||

| 2 |

Consequences: H, S, E & O

These info is extracted from the Failure Effect FE detailed description in the information sheet, afterwards we simply Place Y (Yes) or N (No) Under each of H,S,E,O,N But what they stand for?

| F | FF | FM | H | S | E | O |

| 1 | A | 1 | N | N | N | Y |

| 2 | N | Y | Y | Y | ||

| B | 1 | N | N | N | N | |

| 2 | Y | N | N | Y |

H here refers to hidden failure consequences that we will describe separately below.

S stands for Safety. Where the health of someone might be negatively affected even over the long run. Or when someone might be injured or killed.

E refers to breaching corporate, local or national environmental regulation. That’s can happen if waste material as dust or certain gases or hazardous material escapes to the surrounding environment due to the failure

O stands for the operational consequences that negatively affects production quantity, quality or cost. We had detailed it in our previous chat: 2-Reliability made easy. Whom we need to; Operators or Maintainers?

When there are no H, S, E, or O effect from this failure then the analysis conclude a Non-Operational consequences. That’s actually means that this failure has no hidden effect and wont breach Safety or environmental regulation or won’t cause operational consequences. It only has the direct and indirect costs of its repair. Then, It will be denoted by N in the next step of task selection.

H: Hidden Failure

That’s when the equipment is not actively used. We can find examples for expected hidden failures in valves, standby equipment and protection sensors or devices. The importance of devices or equipment that might borne hidden failures stems from the fact that the design of the other equipment in the system rely on their function. When they fail and get discovered only when they are needed they cause multiple failures. Think about electrical protection relays, pressure reliefs and standby pumps as examples. However, some fail safe valves or relays that rely on mechanical springs to return to safe position can get stuck.

The highest priority is given to the management of the hidden failures. Then we plan to manage the failures with Safety and environmental consequences. This is followed by the failures with operational consequences. Lastly we allocate tasks for the failures with non-operational consequences. For each consequence we have levels of tasks. How to select which level? In the next session.

RCM Decision: Levels of Tasks H1 – > H3

After you know the function(s) expected, the failures that you need to manage and their consequences, you start making decisions about the feasibility of the maintenance tasks. Based on the Yes/No Analysis Y/N of the failure consequences, you start to find the appropriate tasks for those consequences evaluated as existing or Y (Yes). S in this section refers to Safety and Environment as they have the same level of importance when checking the feasibility. Feasibility refers to technical feasible and economically worth doing tasks.

On Level 1 (H1, S1,O1,N1), you check if there is a feasible on-condition task that can detect that the failure is occurring or about to occur. If not->

On level2 (H2,S2,O2,N2), check if there is a feasible restoration (overhauling) task that can decrease the failure rate or avoid the failure totally. If Not->

While in Level 3 (H3,S3,O3,N3), ask if there is a feasible discard task that can decrease the failure rate or avoid the failure totally. Discard means that we install a new spare part or equipment and scrap the old one.

When there are no On-Condition, restoration or discard tasks are found feasible, we shall go to the Default Actions.

| F | FF | FM | H | S | E | O | H1 S1 O1 N1 | H2 S2 O2 N2 | H3 S3 O3 N3 |

| 1 | A | 1 | N | N | N | Y | Y | ||

| 2 | N | Y | Y | Y | N | N | Y | ||

| B | 1 | N | N | N | N | N | Y | ||

| 2 | Y | N | N | Y | N | N | N |

Default Action H4,H5,S4

Those are the: failure finding, combination of tasks, redesign or run-to-failure conclusions that are reached if there are no feasible proactive actions found. But why we don’t see further actions for the O (Operational) or N (Non-Operational)?

For both O & N consequence if no feasible task can be found on the first three rounds O1,O2,O3 or N1,N2,N3, then we shall go to No-Scheduled Maintenance Decision.

For S (Safety and Environment), if there were no feasible tasks on levels S1,S2 or S3, therefore it is compulsory to look for a combination of tasks or to redesign the equipment. This decision is based on the importance of the Safety and Environmental consequences.

For H (Hidden Failures) that cause multiple failures, in case there were no feasible tasks on levels H1,H2 or H3, we shall delve more. On Level H4, we shall look for a failure finding task that we shall chew about in a coming chat.

In case there is no feasible failure finding task we go to level H5. On Level H5, we check if there are any Safety or Environmental consequences for letting this failure happen. If there are no S consequence we shall go to No-Scheduled Maintenance. Otherwise, when there are anticipated safety or Environmental consequences, redesign is compulsory.

No scheduled Maintenance

That’s when we simply allow failures to occur and then repair them. That’s the maintenance old run-to-failure strategy. But, Now it is applied wisely and selected consciously.

In a coming chat we shall walk around the interval selection and who can do the tasks.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment