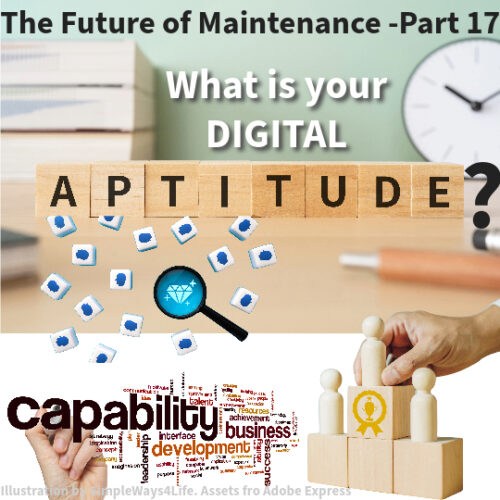

In our previous exploration of machine learning (ML) in maintenance, we delved into its potential to help us predict and prevent equipment failures. By leveraging techniques like predictive maintenance, we’ve seen how ML was used by leading companies to reduce downtime, optimize resource allocation, and enhance overall operational efficiency.

As we look to the future, the integration of ML with emerging technologies like edge computing, explainable AI, IoT, AR, and digital twins promises to further amplify its impact. In this article, we will delve into examples of applying these synergistic technologies. Not only this, these examples can spark innovative ideas of how they can be harnessed to drive innovation and optimize maintenance practices.

from 24 FEb to 01Mar:

By combining the power of ML with these cutting-edge technologies, we can unlock new possibilities. Consequently we need to handle the evolving challenges of modern maintenance operations.

As machine learning continues to evolve, several trends are shaping the future of maintenance. Let’s explore them:

1. Edge Computing

Edge computing involves processing data closer to the source, rather than sending all data to a centralized cloud server. This trend is already making waves in the maintenance industry. For example, Siemens has implemented edge computing for a printed circuit board cutting system at its plant in Amberg, Bavaria. This allowed for real-time analysis and faster response to potential issues.

In practice, this means that sensors on a piece of equipment can process data locally, making immediate decisions about whether to alert maintenance staff or adjust operations. This reduces latency and allows for quicker responses to potential problems.

Reference: Siemens: Edge Computing for Predictive Maintenance

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

2. Explainable AI

As machine learning models become more complex, there’s a growing need for “explainable AI”. Explainable AI models that can provide clear reasoning for their predictions. This is particularly important in maintenance, where decisions based on model predictions can have significant safety and financial implications.

For instance, in aircraft maintenance, it’s not enough for a model to predict that a component will fail; maintenance crews need to understand why the model made that prediction. Companies like IBM are working on developing more interpretable AI models for this purpose.

Also, Explainable AI is one of the key requirements for implementing responsible AI, a methodology for the large-scale implementation of AI methods in real organizations with fairness, model explainability and accountability.³ To help adopt AI responsibly, organizations need to embed ethical principles into AI applications and processes by building AI systems based on trust and transparency.

Reference: IBM: Trusting AI

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

3. Digital Twins

Digital twins – virtual replicas of physical assets – are becoming increasingly popular in maintenance. These digital models can be used to simulate different scenarios and optimize maintenance strategies.

GE has been a pioneer in this area, using Digital Twin as a software representation of a physical asset, system or process designed to detect, prevent, predict and optimize through real time analytics to deliver business value.

Process Digital Twins from GE help manufacturers meet the challenges of fast-changing consumer demand, regulatory requirements and looming generation knowledge gap. Process Digital Twins create models of ‘the best way’ to run a process in a given environment – often referred to as ‘the golden batch’. By identifying the most optimal process to manufacture a given product, plant operators can ensure they are consistently delivering against quality, cost and volume objectives.

Reference: GE: Digital Twin Technology

LOWEST-PRICE-24F-01M

4. Integration with IoT

The Internet of Things (IoT) is providing unprecedented amounts of data for machine learning models. This trend is already well underway, with companies like Caterpillar used a rapid IIoT deployment to gain data-based insights and optimize production at a components plant..

On this project Rockwell Automation is helping give Caterpillar equipment the durability its users expect is the company’s Advanced Component Manufacturing Division. The internal manufacturing group makes transmissions, hydraulic components and other parts for the machine and aftermarket businesses of Caterpillar.

With access to rich data context that it never had before, the division was able to see all of the non-value-added time in the process. And manufacturing engineers were able to improve and optimize the process quickly. So quickly, in fact, that they reduced overall process time by over 5% on day one.

Reference: Caterpillar’s Digital Transformation

from 24 FEb to 01Mar:

5. Augmented Reality in Maintenance

Augmented Reality (AR) is beginning to play a role in how maintenance teams interact with machine learning predictions. Companies like PTC are developing AR applications that can overlay machine learning insights directly onto equipment in the real world.

For example, a maintenance technician might use AR glasses to see a visual representation of a machine learning model’s prediction overlaid on the actual equipment. This could show them exactly where a potential problem is likely to occur and guide them through the repair process.

For GE, The problem was that there were few good ways to tell if the retightened hose nut had hit that sweet spot. Workers with torque wrenches had to rely on their skill and judgment to nail the delicate balance. And it was solved by Wi-Fi-enabled torque wrench which shares the information with the an AR server. Then, it tells the mechanic whether they are properly tightening and sealing crucial jet engine b-nuts. AR will verify the correct value in real time of the hose nut it sees the mechanic working on before the mechanic moves on to the next step.

Reference: The Future of Maintenance – Part6.2, AR setup for Maintenance

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

These trends represent the cutting edge of machine learning in maintenance. As they continue to develop and mature, we can expect to see even more efficient, effective, and intelligent maintenance practices across industries.

Conclusion

Machine learning is revolutionizing the field of maintenance, offering unprecedented capabilities to predict, optimize, and streamline maintenance operations.

As we’ve explored, machine learning (ML) is poised to revolutionize maintenance practices across industries. By harnessing the power of data and advanced algorithms, ML empowers us to predict failures, optimize maintenance schedules, and make data-driven decisions that drive operational excellence.

By integrating ML with emerging technologies like edge computing, explainable AI, IoT, AR, and digital twins, we can unlock even greater potential. These technologies work in synergy to create a comprehensive and intelligent maintenance ecosystem.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment

Comments are closed.