It is important to set up clearly who will do each step in any process. Like this, everyone involved in the process knows his role when it comes to the execution of this process. So, no one is volunteering to do a task one time then expecting that someone else might do it in the next time. The first step to set the roles is to understand the cycle or the process. Then to add these roles to the job descriptions not to the names. After that ensure that the persons who are in this job knows his responsibilities in the material management cycle clearly.

Materials Management Cycle and roles distribution

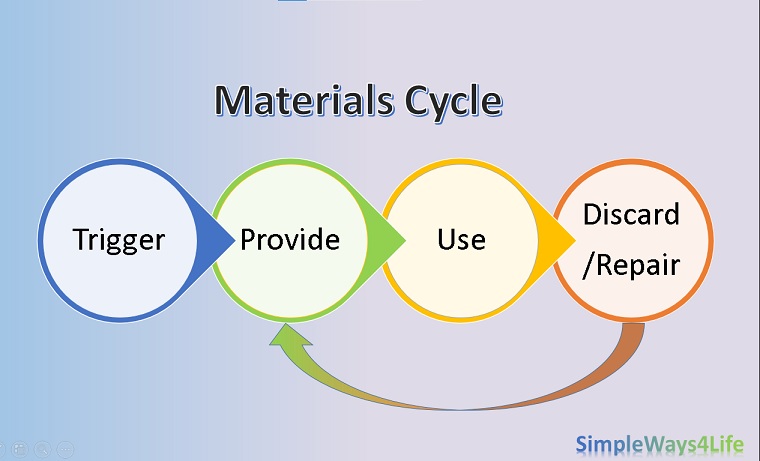

The cycle from a distant look appears simple. It has main 4 steps of Trigger, Provide, Use and Repair/Discard. The Use and Repair stages are obviously done by the maintenance team. While the Trigger will come from the min-max calculations and, it can be done by the warehouse team. And, the provide process is within the scope of the purchasing team. However, the seeds of problems within this cycle lays in the details.

When you go deep inside each stage you shall find a lot of details that can cause a conflict of interest. If the roles are not clearly set for each part of the individual cycles, this can cause conflicts and delays within the materials management cycle.

The Trigger stage

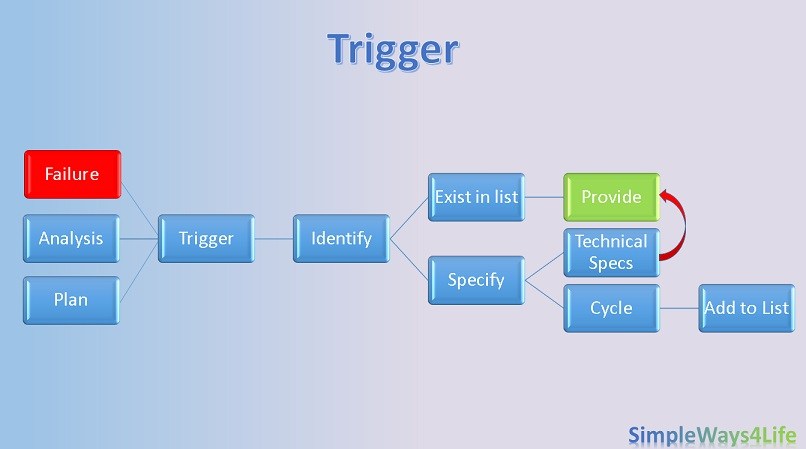

While trigger optimally comes from the planning process, sudden failures impose urgent needs of parts. Both tracks whether a task is under the planning process or an urgent task emerged at site due to failure can bring the need to a part that is not in the store. Unfortunately, this part might be not in the spare part list. Other times , the daily inspection and analysis can come up with a first-time future necessity to replace a part.

However the way the trigger occurred, the identification of the part is your next station. Either the parts carry the identification on site or in the documentation or in the drawings. Maybe the site identification caries the equipment or whole parts code. But, I need an individual component as a seal, a filter element or a fuse. Mapping the site identification to the stores’ code is an art in its own that the team excel with time. Usually from the site you can’t get the warehouse code of the part.

The optimum situation is when the maintenance request comes out of the maintenance schedule loaded with the spare parts codes. But, during the failure either the team will reissue the workorder on an emergency bases. This will print out the correct spare parts codes for this task. Otherwise, the team need to link the technical specs of the parts in the field to the spare parts codes in the warehouse.

Roles of maintenance and warehouse teams if this part is not in the parts lists?

Then it comes to the specify stage. The maintenance team will set a detailed set of specs that enables finding a replacement in the warehouse. If not it enables requesting it from a vendor through a purchaser who is not the subject matter expert. There are not right or wrong role setting. There are general targets as the minimum service time and minimum stock outs. The distribution for the roles aims to achieve those targets. The roles and responsibilities that doesn’t fulfil those targets need to be tuned till it achieve them.

The next step is to decide whether we shall add this new part to the parts’ lists that run automatically on the min-max system – If it exists-.

The maintenance team is responsible for the identification, the specification and, the min-max or reorder point settings. While the warehouse team is auditing the time those parts stay on the shelf and their warehouse cycle. Also, the warehouse team is responsible of declaring stagnant items. And, they are responsible for updating the stocks and facilitate reaching the physical locations of the parts in the warehouse. <

Does the purchase team has comments about the technical specs?

The purchase team is responsible for maintaining good relations with a well selected shortlist of vendors. However, Sometimes vendors either decline or send asking for more clarifications. Then the purchase team can comment on the incomplete, inconsistence or obsolete technical specs. This does not conflict with the role and responsibility of the maintenance team in specifying the technical specs. But, it helps the maintenance team to understand the market condition and the vendors minimum needed specs.

Also, for some common parts, the technical team might include the name or manufacturer code of a certain manufacturer. When the purchase team is aware that this is a common part as seals, bearings or fuses, then they can ask to tail the technical specs with “or equal”. This also might be set as a flag in the inventory software. This way, the purchase team will look for the best price of the equivalent parts. However in some cases there is a unique feature in that manufacturer, as tighter tolerance or galvanized terminals. Then the maintenance team can refuse to accept the supply of equivalent parts if this additional service can justify any additional cost.

A final note about the roles

Shall we set our reorder points to automatically launch purchase requests? Why? Why not?

Do we need the warehouse team or the technical team approval for purchasing the parts that reached its reorder point? Why?

Shall every parts order be issued by the maintenance team? Why?

In Conclusion,

The triggers for a needed material are initiated whether from the plan, an analysis or a failure. The next step is to identify the parts needed for this task. Usually previously planned tasks have their parts ready with the warehouse codes. Sometimes there is a new task that we need to plan or an urgent part that we need to purchase and it is not part of prepared parts lists. At this point we need to have a closer look to the details of the trigger processes of the material management cycle.

There is the identification of the part, the needful technical specification to locate a similar or replacement part at store. Or, we might need to reach out for some vendors to supply the part. Ensure that the the provided technical specs clear and sufficient. Do we need it from a certain manufacturer or an equivalent would fit? Shall we add it to the auto reorder cycle? Who is responsible for each stage?

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

2 Comments