Most maintenance teams don’t fail because of laziness or lack of tools — they fail because they’re missing the invisible structure that holds everything together: a real maintenance program. You can make a maintenance program successful by fulfilling six essential components that form the backbone of effective maintenance operations. These elements ensure your maintenance efforts are organized, proactive, and measurable, rather than reactive and chaotic.

A maintenance program is much more than a collection of tools or a schedule of tasks. It is an integrated system built on these six pillars — the invisible structure that holds everything together. When these components are in place and working harmoniously, maintenance teams can thrive. They can reduce downtime, extend asset life, improve safety, and optimize costs. This is how you make a maintenance program truly successful.

This is exactly what I teach in my course Secrets of Building a Maintenance Program

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

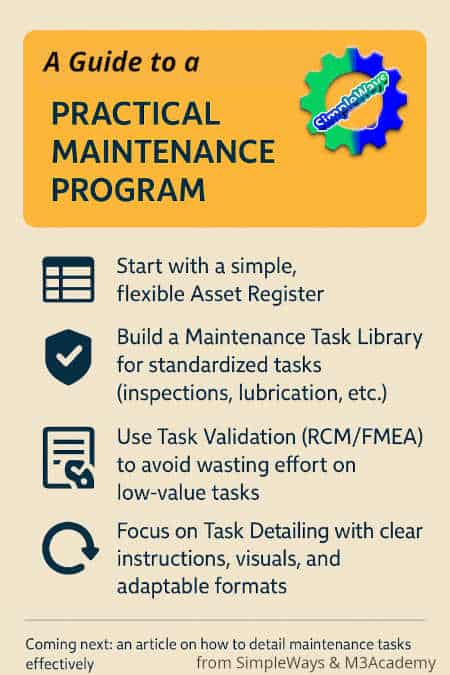

— and here are some of the key components we always start with to build or update a maintenance program:

Asset Register: The Key to Effective Asset Management

An asset register is a comprehensive list of all the equipment, tools, and resources owned by an organization. It serves as a centralized record that tracks each asset’s unique ID, location, function, and specifications. This register is crucial for efficient management because it allows organizations to know exactly what they own, where it is, and how it’s being used.

Start with a simple asset register

many organizations find that creating and maintaining a sophisticated asset register often becomes a burden. Implementing complex systems can require a high-level team, specialized software, and significant resources, which can be overwhelming for smaller teams. This is where simplicity can shine. Google Sheets, for instance, is an intuitive, flexible tool that allows companies to build a fully customized asset register. Most importantly, it allows you to start without the complexity of expensive systems.

Using Google Sheets or similar apps for asset tracking provides several advantages. It’s easy to update, expandable, and offers clear visibility of all assets in one place. It’s an excellent starting point for a maintenance program, offering a manageable way to track asset life-cycle and maintenance needs. Moreover, it can breathe new life into an existing maintenance system by making asset data more accessible and streamlined. The flexibility of Sheets means that you can continuously improve and scale the system as your needs evolve, without the need for a sophisticated IT infrastructure.

Ready to transform your mindset? Click and Get your copy > Now For Sale on Simpleways.life & Amazon

Key constraints when creating an Asset Register

Each asset in the register is assigned a unique identifier, ensuring that no two items are confused with one another. The register also notes the location of the asset, whether it’s in a specific office, warehouse, or field. Its function outlines the role the equipment plays in the business process, while the specifications detail the technical or performance requirements. You can even add links of all the documents related to this asset.

Why does this matter? Simply put, you can’t manage what you haven’t defined. Without a clear record of assets, it becomes challenging to track maintenance schedules, ensure compliance, or even plan for future investments. An asset register prevents unnecessary duplication of equipment, helps with budgeting, and supports better decision-making by providing detailed insights into the organization’s resources.

In short, an asset register is not just a list; it’s a vital tool for maximizing the value of your assets, minimizing waste, and streamlining operations. Moreover in “Secrets of building a Maintenance Program” we work together on creating the equipment identifiers and point out to most of the useful data that allows you to launch your maintenance program and where to find these data.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Maintenance Task Library: The Heart of Your Maintenance Program

A Maintenance Task Library organizes essential maintenance tasks for easy access. It standardizes processes like inspections, replacements, lubrication, and calibration. Each task is linked to OEM manuals for accuracy and compliance. The library also incorporates past experience to optimize task execution. Safety practices are embedded to ensure employee well-being and operational safety.

This library becomes a crucial part of your maintenance program, offering clear guidelines for routine upkeep. It helps technicians follow proven methods, reducing errors and downtime. By linking tasks to official manuals and real-world experience, you ensure consistency in maintenance efforts. The inclusion of safety protocols also minimizes risk during each task.

A well-maintained Maintenance Task Library streamlines operations, supports the maintenance program, and contributes to long-term equipment reliability.

Where to collect these task details from? That’s one of the key parts of our “Secrets of a Maintenance Program Training”. Together with collecting all the tasks needed for asset upkeep, the below insights about the collected-tasks validation and clarity lays a robust foundation for your maintenance program.

Task Validation: Is It Worth Doing?

Task validation is an essential process for optimizing your maintenance program. Not all maintenance tasks are equally important, and blindly following OEM manuals without considering the real value can lead to wasted time and resources. Task validation answers the question: Does this task add value, or are we just doing it to stay compliant?

Start by categorizing tasks based on their importance. Use tools like RCM analysis or Failure Modes and Effects Analysis (FMEA) to assess whether the task is critical for reliability. For example, some tasks may be required by warranty or regulations, but that doesn’t necessarily mean they’re contributing to operational efficiency.

- RCM analysis helps prioritize tasks based on the likelihood of failure and the consequences of failure, ensuring that only high-priority tasks are done frequently.

- FMEA identifies potential failures in the equipment and evaluates the severity, likelihood, and ability to detect these failures, guiding you toward more focused, efficient tasks.

By performing task validation, you can streamline your maintenance efforts. For tasks that don’t directly impact equipment performance or safety, consider reducing frequency or replacing them with more effective alternatives. This ensures that your team spends time on the tasks that truly keep your equipment running smoothly.

RCM – Reliability Centered Maintenance – and FMEA – Failure Modes Effects Analysis – are core components of our course: “Mastering the Reliability Mindset“

from 24 FEb to 01Mar:

Detailing for Clarity: Making Maintenance Procedures Understandable

Clear, detailed maintenance procedures are essential for effective execution. Without proper detailing, even the best-trained teams can miss steps, waste time, or create safety risks. To ensure your maintenance procedures are understood and followed correctly, consider the following practical approaches:

- Use Step-by-Step Instructions

- Incorporate Visual Aids

- Leverage Digital Tools for Real-Time Updates

- Iterate and Adapt Based on Feedback

But we are going to detail them in the coming article, wait for us

As a sum up to what we had discussed today:

Building a strong maintenance program doesn’t require complex software or large teams. Starting with a clear, well-structured asset register—even one built in something as simple as Google Sheets—can bring clarity, accountability, and control to your operations. When paired with a flexible and evolving Maintenance Task Library, this foundation supports consistent maintenance practices, reduces downtime, and helps teams work smarter, not harder.

But the real power lies in how well tasks are understood and executed. That’s where task validation and detailing come in—ensuring each task has a purpose, follows best practices, and is clear to those performing it. In our next article, we’ll dive deeper into how to detail maintenance tasks effectively—using step-by-step instructions, visuals, and real-time tools—to make your maintenance program both reliable and practical in the field.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment

Comments are closed.