In the evolving maintenance landscape of 2025, relying solely on traditional checklists, reactive repairs, or even classical predictive maintenance is no longer sufficient for maintenance practitioner. While predictive maintenance has helped anticipate failures using sensor data and scheduled interventions, maintenance practitioners must now move beyond these classical methods to stay ahead.

At the same time, maintenance practitioners have unprecedented opportunities to benefit from advanced AI tools. These tools enhance their knowledge, skills, speed, and autonomy by automating routine tasks, analyzing complex data patterns, and generating actionable insights. Leveraging AI empowers practitioners to make smarter decisions faster and optimize maintenance operations like never before.

Ready to transform your mindset? Click and Get your copy > Now For Sale on Simpleways.life & Amazon

This article explores the essential tools every maintenance practitioner should focus on in 2025. We will discuss data-driven maintenance, the role of AI and machine learning, aligning maintenance strategy with business goals, practical tools and models for continuous improvement, and the strategic prioritization of tasks through Reliability-Centered Maintenance (RCM). Together, these approaches equip maintenance practitioners to excel and deliver maximum value in today’s complex industrial environments.

Maintenance Practioners to Embrace Data-Driven Maintenance

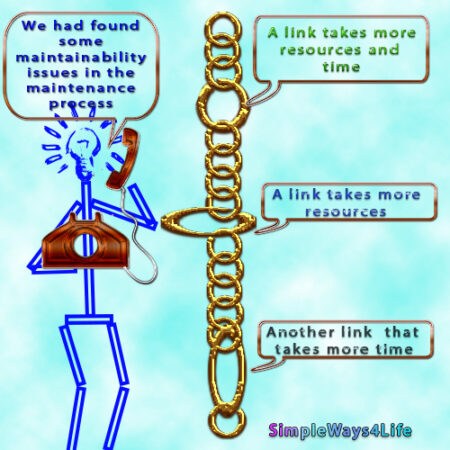

Data-driven maintenance is revolutionizing how maintenance practitioners operate. By collecting and analyzing vast amounts of operational data, maintenance practitioners can predict equipment failures before they occur. Predictive models enable practitioners to schedule maintenance proactively, reducing unexpected downtime and lowering repair costs. According to McKinsey & Company, While predictive maintenance can generate substantial savings in the right circumstances, in too many cases such savings are offset by the cost of unavoidable false positives.

For the maintenance practitioner, mastering data analysis tools and understanding predictive analytics is no longer optional but essential for competitive advantage. You can find practical techniques @ my training course: Secrets of Building a Maintenance Program

BESTPRICE-ENDS-04FEB

McKinsey & Company, continue to say, there are other powerful ways to enhance a business’s maintenance-service organization and create value from analytics-based technologies. Many events are difficult to predict, and the costs associated with taking preventive action are substantial; in contrast, the savings from predicting these events a few days in advance tend to be modest. And any equipment shutdown is a hassle—whether the machine simply breaks down on its own or is stopped during a deliberate, preventive shutdown.

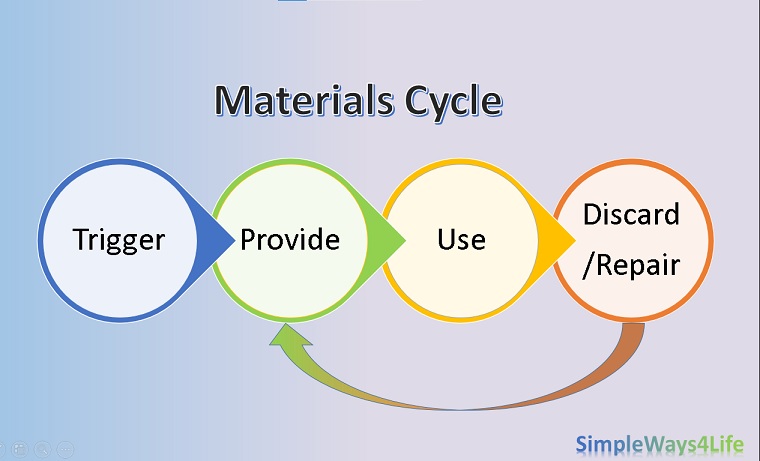

This can be solved by employing a data-capture strategy. Analytics models need data, and a strategy for master-data management and governance will be critical for success. Executives therefore need to ensure that data from all sources is being captured, whether through sensors or through logbooks.

Also, a data-friendly mind-set, is essential. If there is no analytics-adoption mind-set and leaders are unable to communicate the benefits to everyone involved, the organization is much more likely to reject the data model recommendation as a threat, rather than adopt it as a source of opportunity.

Leveraging AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are powerful allies for the modern maintenance practitioner. These technologies analyze complex data patterns that are difficult for humans to detect. For example, AI can optimize shift reports by automatically summarizing key metrics and trends, freeing maintenance practitioners to focus on decision-making. Machine learning algorithms can identify subtle failure patterns, enabling early intervention. That’s The Road Ahead for ML in Maintenance.

Generative AI tools also assist in generating actionable insights and automating routine documentation tasks. Maintenance practitioners who harness AI and ML can improve accuracy, speed, and effectiveness in maintenance operations, as highlighted in recent Maintenance Technology Magazine features. You can master Prompt Engineering for Maintenance through my course: Secrets of Building a Maintenance Program

BESTPRICE-ENDS-04FEB

ChatGPT -as an Example– created a disruptive technology wave that affects everyone’s life. So even if you didn’t explore it till now, you at least heard about it. Moreover, you might have created an opinion about it even before trying it. This opinion reflects your general reaction to the rapidly digitalized world. This doesn’t mean that ChatGPT or similar apps are bullet proof or they are the magical solution to every problem. But it really provides a good assistance and a starting point if you feel lost and don’t know where to start from as far as I explored it.

Aligning Maintenance Strategy with Business Goals

A successful maintenance practitioner understands that maintenance is not just a technical function but a strategic one. Aligning maintenance plans with overall business objectives maximizes return on investment (ROI). This means prioritizing maintenance activities that directly impact production quality, safety, and cost-efficiency. Maintenance practitioners should collaborate closely with operations and finance teams to ensure their strategies support broader company goals. McKinsey consultants emphasize that organizations with aligned maintenance strategies experience better asset reliability and financial performance. Thus, maintenance practitioners must develop skills in business communication and strategic planning.

One of the best places where you can practice creating a maintenance strategy is Secrets of Building a Maintenance Program

BESTPRICE-ENDS-04FEB

Practical Tools and Models for a Maintenance Practitioner

To improve maintenance programs step-by-step, maintenance practitioners should leverage practical tools such as data visualization software and key performance indicators (KPIs). Visualization tools help translate complex datasets into intuitive charts and dashboards, enabling practitioners to quickly identify problem areas and monitor progress. KPIs such as mean time between failures (MTBF), mean time to repair (MTTR), and overall equipment effectiveness (OEE) guide maintenance focus and resource allocation. By regularly reviewing these metrics, maintenance practitioners can implement continuous improvements. This hands-on approach ensures that maintenance programs remain effective and aligned with operational realities. You can learn how to generate customized KPIs here: Secrets of Building a Maintenance Program

BESTPRICE-ENDS-04FEB

Maintenance Practitioner Prioritize Tasks

Reliability-Centered Maintenance (RCM) is a strategic methodology that helps maintenance practitioners prioritize tasks based on risk and impact. RCM focuses on understanding the functions of assets, potential failure modes, and their consequences. Maintenance practitioners use RCM to allocate resources efficiently, ensuring that critical assets receive the highest attention while less critical equipment is maintained appropriately. This risk-based approach optimizes maintenance efforts, reduces unnecessary work, and enhances asset reliability. Reliabilityweb.com highlights RCM as a best practice framework, essential for maintenance practitioners aiming to optimize maintenance in complex environments. Practice on a virtual production line here: Mastering Reliability Mindset & Practices

BESTPRICE27JAN-01FEB

Conclusion

The maintenance practitioner in 2025 must blend traditional skills with advanced tools and strategic thinking. Embracing data-driven maintenance, leveraging AI and machine learning, aligning strategies with business goals, utilizing practical tools, and applying Reliability-Centered Maintenance form the foundation of modern maintenance excellence. These tools empower maintenance practitioners to reduce downtime, control costs, and support organizational success. For those seeking to deepen their expertise, courses like Secrets of Building a Maintenance Program offer comprehensive training to master these essential tools and skills.

This article aims to equip every maintenance practitioner with the knowledge to thrive in 2025’s fast-evolving maintenance landscape.