When we start to chat around a certain topic, it is wise to start by laying some common foundations. So, lets start by some literal and maintenance definitions of Reliability to demystify it.

Literal definition and synonyms of Reliability.

It is the the quality or state of being reliable. Reliable means it is suitable or fit to be relied on i.e. DEPENDABLE, TRUSTWORTHY and giving the same result on successive trials

Merriam-Webster

That’s the literal definition of reliability. Its importance stems from the fact that those literal definitions are the ones that we learn from life. They form our perception about the word. This perception is a universal one. Thus it carries a lot of energy that it shapes how we perceive the word in any sentence or context. Then later during our maintenance career we start to hear about Equipment Reliability and the Reliability centered Maintenance. At this point we have diverse ways to go.

Reaction to new understandings

- We separate what we learn at work from our life perceptions. Then we struggle to comprehend the new information. That would be possible if we have no prior perception of the subject. Unfortunately, Reliability and its synonyms: dependability, responsibility, sureness, trustability ,and trustworthiness are everywhere in our life. It is part of how we see other people, our home appliances, our old or future car and so on.

- Alternatively, we may rely on the inherited perceptions which might serve you well or might not. It depends. Sometimes we deeply believe in our prior understanding that we resist any new point of view. Moreover, we try to enforce our old understanding to new different situations. We had chatted together about this topic here: How to transcend old maintenance perceptions?

- A better approach is that we intentionally asses the new understanding. Then, if it works well for us in the current situation, we give it a chance. We start to investigate if we have old perceptions about the subject. Then we compare the old and new understandings. As a result, we may intentionally replace, correct or add new understanding to our maintenance management mind That’s we do in our training about the maintenance program foundations. You can join it here in Arabic or English

Maintenance evolution

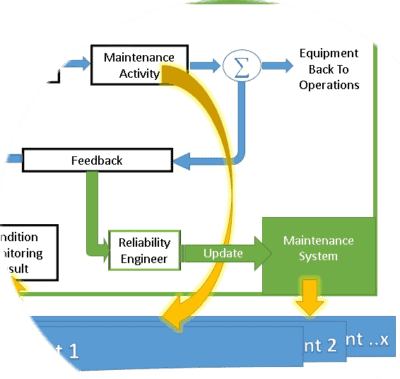

Generally speaking, maintenance follow a mix of two main strategies. The first strategy: maintenance is reactive i.e. it adopt the “repair it when it fail” strategy. This reactive approach was the only one available 100 years ago. Later on, another strategy dominated the maintenance practices. This time the focus was on proactive actions. It started by strict scheduled overhauls and timely replacement of parts or complete machines . And, 40 years ago i.e. in the 1980’s, condition monitoring started to reshape the maintenance proactive strategy. The condition monitoring changed the proactive strategy to be condition based for some main critical equipment ,and not the blindly scheduled tasks. In other words, to be proactive we schedule an action before an equipment fails. This planned action is either taken based on calendar dates, the accumulated operation hours, the accumulated operation numbers or the new comer which is the equipment condition.

The proactive approach never dominated the workplace. Why? there are many reasons:

- Not enough manpower to do preventive tasks for every piece of equipment

- No inhouse maintenance team in the first place

- Recently, Complex Equipment fails randomly even while we do the preventive maintenance activities as per the book. This resulted in additional calendar based tasks. This takes us back to the first item; the unavailable but needed additional manpower.

- Sometimes, over-replacement of parts before their expected life time increases the maintenance cost drastically.

- Special skills needed are not available

- Special tools needed are not available

Why Reliability was introduced to maintenance?

As usual, the aviation and defense industries pioneer new techniques. Their equipment need to be safe, performing its intended functions with minimum cost. That’s why in the 1970’s they funded studies to enhance the maintenance performance. Why? At that time the complexity of the systems resulted in failures that are not age related. Moreover, chasing the minimum time between failures and replacing or overhauling the equipment before it, turned to be nonsense. The target behind the RCM approach/process/platform/framework is to avoid the accidents/surprises and save the time, cost and extra manpower needed in the different maintenance strategies..

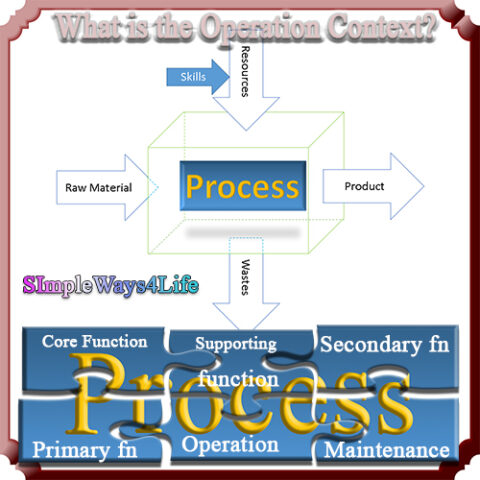

What is RCM?

RCM (Reliability-Centered Maintenance) is not a maintenance strategy. It is a process to generate a maintenance strategy. It is some sort of well-structured deep analysis based on the collective experience of the industry or the workplace. RCM takes the maintenance out of the nutshell of maintaining the prescribed function or status of the equipment. It adds new perspectives to the maintenance program to come up with the best maintenance strategy and cycle for each specific equipment. The new perspectives added to the maintenance tasks selection and planning includes:

- original purpose from purchasing the equipment,

- user needs, the machine capability,

- operation context,

- failure context,

- failure consequences,

- and the safety of the personal and equipment

One of the simple but representative definitions of RCM can be found in John Moubray book, RCM II. It says:

Maintenance: Ensuring that physical assets continue to do what their users want them o do

John Moubray, RCM II

Reliability-Centered Maintenance: a process used to determine what must be done to ensure that physical assets continue to do what its users want it to do in the present operating conditions

John Moubray, RCMII

In case we link this definition to our daily life, we can see that we actually seek reliability in all our belongings. We purchase them in the first place to perform a function we need. A the same time, we keep an eye on how long it will serve us and what are the efforts needed to maintain the original performance we purchased it for.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

3 Comments