Traditionally when we are building a maintenance system or even a maintenance program for a machine, maintenance team takes the lead. However, when you plan to use RCM (Reliability-Centered Maintenance) to optimally prioritize, select or abandon some maintenance activities, you need skilled & experienced operators as well as you need skilled maintenance team.

Why? Because the first steps to RCM are to think and document the operation context of the machine. And to record how reliable & safe the machine is for the operators. Usually complete failures aren’t doubtable but their reasons’ are arguable. Also partial or secondary failures opens wide arguments unless agreed upon. That’s the next step after we had painted together an understanding for reliability and it synonyms, here

How operators and maintainers see the equipment and its failures?

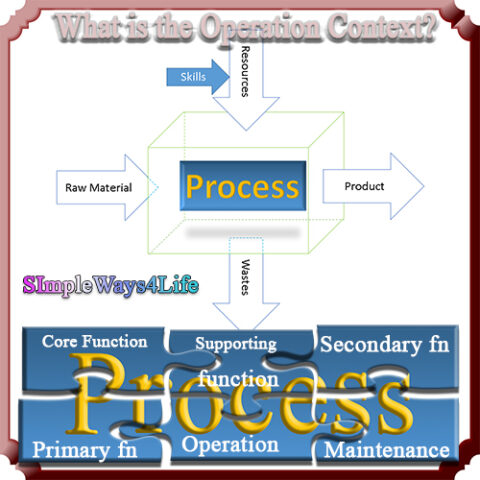

A crucial part of RMC is the operations context. You can take a machine out of the operation process for repair or maintenance. Even you can take it to the repair shop to do a more sophisticated job. While, during the operation process it is part of the flow of the core and the secondary processes.

We need to understand what operations mean in the first place. The focus in this chat will be on the production operations. Production operations involve a series of steps to produce a product. We usually speak about physical products. The processes to produce a physical product includes core processes, supporting processes and management or control activities. Regardless of the size of the business, the production process involves raw material that is transformed into a sellable product.

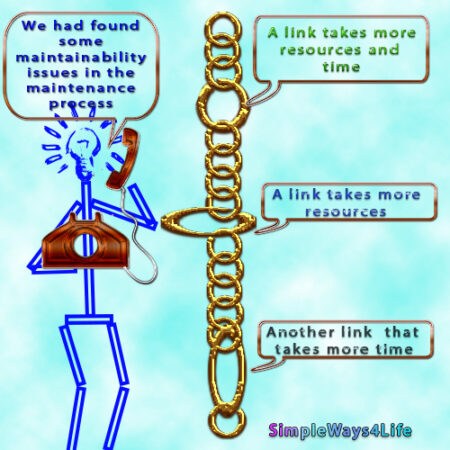

The core process can involve a series of cascaded processes closely interlinked. Or, there might be a margin for slip between the output of each machine and the input of the next machine. This buffer gap is the number of products and/or the time the next machine will be idle if this machine didn’t return to operation. Same applies for the previous stage. Either it stops when this machine stops or can produce and stack the product till its following machine returns to normal operation.

Moreover the stock i.e. raw material under processing might be turned to waste immediately when a machine fails. This puts a pressure on the operators and maintainers. Otherwise it might be reprocessed if the machine return to operation within a certain period of time. That’s even more stressful with each clock tick. The maintenance team feels that they are chasing the clock ticks which seems running faster in such situations.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

Secondary equipment vs Secondary function

RCM does not discriminate equipment based on their level in the operation. In other words, a side conveyor that moves the final product away need to be analyzed as part of the operation context. Even if the secondary process does not stop the main process immediately, it will, after sometime.. The secondary functions do not stop the process but affects the operation context. It is always easier with examples.

- A pump pumps the water with the required Q but it has a leakage. So, this means that there is a failure in its secondary function of containing the liquid pumped

- A flight is safe to fly but the coffee machine is not working. The passengers will be moved safely to their destination, which is the primary function. But the passengers were not satisfied without coffee.

To add new understanding to the maintenance management mind Join our training about the maintenance program foundations. You can join it here in Arabic or English

A note about soft products

Anyhow, soft products also involves a a process or a series of steps to produce a soft product. If we consider this article as a soft product, it involves preparation, writing, editing, proof reading, graphics design, publishing and marketing on the social platform. When there are multiple persons responsible for those tasks, it is like a cascaded interlinked process. Every stage of the process is hammering the previous one for delayed or inadequate output.

The operators expectation

That’s a critical point because there is an original design capability of the machine regarding many aspects. The design for a pump considers the delivery and suction heads and the delivery volume to select the motor that will drive the pump. This also includes the material pumped. Is it water, heavy fuel or what? Anyhow the manufacturer had made a big range of pumps with different capabilities. Do you know which one fits your need? Do you need to pump a 800m3/hr or a 900m3/hr? Well, if you had selected a 900m3/hr pump and that’s your minimum acceptable range then maintenance can’t grant a flat rate 900m3/hr for long. Usually you add a 5% or 10% surplus capacity to cater for variations in operation context and natural wear. That’s not overdesign.

However, RMC is very generous in its study of the function of the equipment. It has an option to reach to a conclusion of redesign i.e. upgrade the equipment if it is not matching the needed performance. The equipment was purchased for an original function. This function need to show the operation context needed by the operator and to compare it to the equipment original capability. There is no maintenance task that can increase the power of a motor by 20% if that was the failure seen by the operation team.

How Maintainers see the machine operation?

The maintenance team can collect the data about the equipment productivity, speed and standard setups in the book (i.e. the operation manual and equipment data sheet). However, how the machine is actually operated on the shop platform and what is expected from it is mainly within the experience of the operators. Moreover, many times, you can’t find those locally developed details in the SOP’s (Standard operation procedures) whether it is locally developed or provided from the supplier

Many members of the maintenance team are excellent in dismantling and reassembling an equipment. They know the details of what is inside the machine and what might goes wrong and how to return to the original capability. However, many of them do not see the cost behind the plant stoppage, raw material scrap or downgrade or the maintenance cost either from parts or overtime. They want to deal with the machine as a standalone equipment. This is not the case. The context of the machine operation, how it is operated and induced failures are equally important to repairing the machine. There might be some changes in the operation context that expedite wear and so maintenance and expands maintenance cost

Moreover, product transportation and a control equipment as the product quality measurement tools are equally important to the main product. Overlooking those functions can result in out of spec product or in a chaos that would induce failures and preach safety.

When the maintenance team focuses only on how to repair a failure, it loses the big picture. Usually this result in an unsatisfied operations team. Moreover, it results in increased maintenance costs and decreased cycle. All this happens if the operation context is not clear and recorded.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

4 Comments