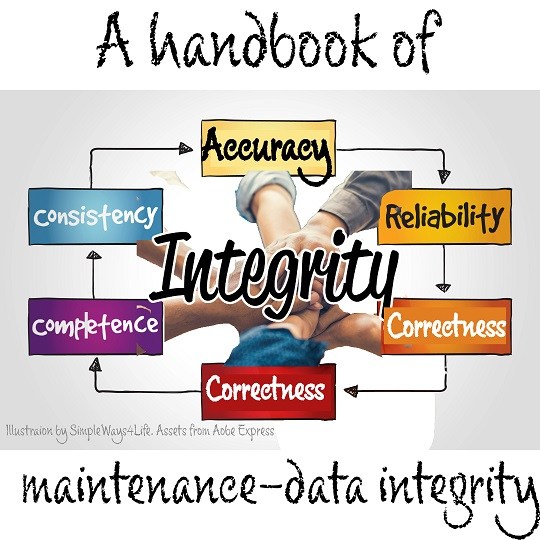

A handbook of maintenance-data integrity

Ensuring data integrity in maintenance is fundamental for maximizing the effectiveness of maintenance practices, minimizing downtime, and supporting overall asset reliability. Let’s see how to achieve this.

Ensuring data integrity in maintenance is fundamental for maximizing the effectiveness of maintenance practices, minimizing downtime, and supporting overall asset reliability. Let’s see how to achieve this.

Ongoing advancements and market competition contribute to the evolving landscape of tech. So don’t miss this chance and start by understanding the available technology and find out how you can embrace one of them simply in your current maintenance and production practices.

With this guide, your maintenance system can continuously evolve as time goes on. It is the roadmap that we can rely on for 2024.

By leveraging basic tools and free online digital resources, organizations can embark on a journey towards a more efficient and reliable maintenance framework. This will make the roadmap to take maintenance to the next level in 2024 real.

The transition from 2023 to 2024 offers an invaluable opportunity for us on the personal and organizational levels. That’s not only to unbox new opportunities and foster innovative thinking but also to conduct a comprehensive roundup of lessons learned.

Embracing common sense in maintenance leads to more effective decision-making, a user-centric approach, and a culture of continuous improvement.

The key is in finding the balance in the now context between looking for a reason, waiting for an intuition and, following the common sense. Let’s see how we can reach there.

The successful implementation of maintenance reliability concepts is intricately tied to effective coaching. That’s in order to foster a reliability-centric culture, align teams with strategic objectives, and many other objectives explored in this article.

You can build the complete maintenance process around data visualization. There is no activity in maintenance that won’t get better by adding data visualization. it’s essential to choose the right types of charts and graphs based on the specific goals and characteristics of the data.

Run charts are a valuable tool in reliability engineering for continuous monitoring, trend analysis, and decision support. They contribute to a proactive and data-driven approach to managing and improving the reliability of systems and processes.

There are many different techniques and tools you can leverage to visualize data. This series is to know which ones to use and when. We had started by one of the most relevant tool to our daily maintenance and management work which is the Pareto Chart. We expect that all maintenance team and professionals would like to know these skills in order to take and understand data-based decisions.

Why we make choices? Embracing any change would need a choice to do things differently. What you may do and what you may not do when you feel bored at work or over stressed? Do you think of changing your work place? Do you think of changing your career? what if you come to know about a new tool or technology that would yield better results, will you try to apply it? Or at least learn more about it?

Our best version is always changing. Our environment and its rapid evolution adds touch-ups to how the end image will look like between now and then. However at any point of time, we have the freedom to switch to a different version that suits us better. The two main aspects of the best version we chose are authenticity and free evolving.

Reaching the highest good in our life is closely linked to reaching the highest good in its parts. To reach the highest good of the maintenance process we include a detailed explanation about the mental constructions that defines our understanding for the highest good. Then we detailed some examples from maintenance process’ highest good.

Seeking to know and apply how to move forward and propel your career and workplace toward their brightest future will give your life and work their true meaning.

The core idea is that as your knowledge or knowing grows, the tools that will unfold between your hands will corollate to your relative position on the track. Exploring further forward on your track is a great motivator to continue and grow. Then you will be able to figure out how you can use digital tools creatively to create creative tools.

It is worth noting that mastery can propel creativity forward or block it. This is the fact even though creativity and mastery seem to be entangled because the key ingredient for both of them is the knowing. let’s first understand the border lines between mastery and creativity.

Our first step to mastery is the knowing. We need to know our track and the target we would reach by following this track. But, we need to keep in mind that there are many tracks within the same skill. Each track has its own joyfulness, challenges, tools and most importantly a target. At any time we can switch to another track once we have the enough knowing about it.

The first step to digital confidence as well as any other sort of confidence is that you want to develop the awareness of the challenges that you are facing. And, to develop the consciousness of the alternatives to face those challenges.

Succeeding in a digital world is only the matter of developing a digital confidence that you will succeed in every new interaction with the digital world even if the context changes. This needs practice. And, some understanding of what happens behind the user interface UI.