Reliability is a perspective through which we see our assets and processes. There are many factors that work together to build this perception. Regardless of what statistical analysis shows and what indicators say, reliable assets and processes are just like reliable humans, you know them with experience. So besides data, tools and team, our intuitive thoughts labels anything around as as reliable or not.

Creating a subconscious perception of reliability involves fostering an environment and practices that consistently reinforce the idea of dependability, trustworthiness, and consistency. Here are some strategies to build a subconscious perception of reliability

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Consistent Performance: Consistently deliver reliable products or services to build trust and confidence. To achieve this, maintain a high level of quality in all aspects of operations to establish a reputation for reliability.

Meeting Commitments: Consistently meet deadlines and delivery commitments. One of the keys to success is through upholding agreements and promises to demonstrate reliability in business relationships whether internally or externally.

Consistent Communication through ensuring that communication about reliability is clear, concise, and consistent across all channels. Also, reiterate key messages about reliability regularly to reinforce the importance of dependability.

Who generates the Reliability perspective?

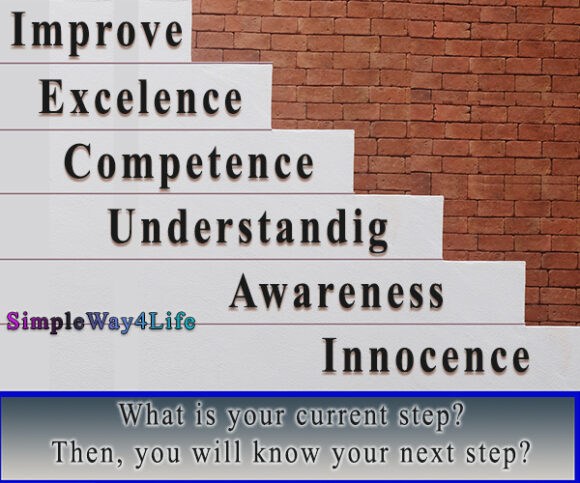

Reliability is the result of continuous collective efforts. Usually we label our team and practices as “maintenance and reliability”. This happened because reliability when introduced to the manufacturing business it was simply like an upgrade to maintenance. But with time it was discovered that maintenance team alone can’t create the reliable asset perception. Reliability relies on data. But, not only maintenance data. The whole organization data together yield the reliability results. These data is processed via tools that converts them into useful information that support decision making. But, the team in maintenance and other business unit who blends this data, its analysis and information based decisions to make the reliable work place a reality.

Data plays a crucial role in maintenance across various industries and, for business in general. However in every step of the data cycle, the Maintenance and Reliability Team has an input. The team collects the it whether manually or via tools. Even if IIoT sensors collects the data and send it directly to the database, the team maintains those sensors. You can read a deep insight about data collection here: The Steps before assurance of maintenance integrity – Step A

LOWEST-PRICE-24F-01M

Then they check the data validation and analyze it. The business digital systems that supports the team as CMMS or ERP plot trends, calculate KPIs or even send an alert based on the control limits the team added to the system. However, the team is who takes an action in response to those alerts or takes a decision based on those trends.

The maintenance team uses this data for:

Condition Monitoring: Data provides insights into the condition of equipment and assets. Regular monitoring and analysis help identify potential issues before they escalate, allowing for proactive maintenance rather than reactive responses.

Predictive Maintenance: Anticipating maintenance needs based on historical and real-time data. Predictive maintenance minimizes downtime, reduces the likelihood of unexpected failures, and optimizes the scheduling of maintenance activities.

Preventive Maintenance: Scheduled maintenance to prevent equipment failures. Data on equipment usage, historical failures, and industry best practices guide the development of preventive maintenance schedules, extending the lifespan of assets.

Root Cause Analysis: Identifying and addressing the root causes of failures. Historical data and failure analysis help in understanding the root causes of equipment failures, enabling organizations to implement corrective measures and prevent recurrence.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Reliability Improvement: Enhancing the overall reliability of systems and equipment. Data aids in tracking reliability metrics, identifying patterns, and implementing continuous improvement initiatives to enhance overall system reliability.

Emergency Response Planning: Preparedness for unexpected events or failures. Developing and implementing emergency response plans to address critical failures promptly and minimize downtime.

The organization needs this data for:

The following aspects shows the importance of data for the organization and all the business units within it. That’s to say, the following data usage fields are beneficial but not only for maintenance.

Asset Management:: Data helps manage the entire lifecycle of assets, from acquisition to disposal. It aids in tracking maintenance costs, assessing asset performance, and making informed decisions about repair or replacement.

Resource Optimization: Efficient allocation of resources (labor, materials, time). Data-driven insights enable organizations to optimize resource allocation, ensuring that maintenance tasks are performed cost-effectively.

Budget and Cost Management: Data helps track all business units expenses, analyze cost trends, and implement cost-effective maintenance strategies, contributing to overall budget management. Moreover, Budget planning relies on the historical records of the cost elements of the previous years.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Informed decision-making for strategies. Data-driven insights empower managers and engineers to make informed decisions about equipment r, replacements, and the optimization of the processes.

Documentation and Auditing: Keeping accurate records for auditing and reporting. Various documentation tools for data keeping ensure accountability, and provide a historical record of maintenance and all activities. This is beneficial for internal and external audit and certification activities.

Using Data for external relations

Materials and Vendors management: Managing relationships with equipment suppliers and service providers. Coordinating maintenance and production activities with vendors, evaluating supplier performance, and ensuring timely delivery of parts and services. This ensures optimal stores and frees unnecessary budget used to stock spare parts and production material.

Regulatory Compliance: Adhering to industry regulations and standards. Environmental data, safety records and Maintenance records are often essential for demonstrating compliance with regulatory requirements, ensuring safety, and avoiding legal and financial repercussions. Adhering to environmental regulations. Example: Implementing maintenance practices that align with environmental standards, such as proper disposal of hazardous materials. Also, Conducting safety assessments, addressing potential hazards, and implementing safety measures in accordance with regulatory guidelines.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

In summary,

Data is foundational to effective maintenance practices. It empowers organizations to move from reactive to proactive maintenance strategies, optimize resource allocation, and improve overall asset reliability. By leveraging data, maintenance teams can make informed decisions that positively impact equipment performance, operational efficiency, and the bottom line.

Building a subconscious perception of reliability is a holistic effort that involves every aspect of an organization’s operations, culture, and communication. By consistently demonstrating reliability in actions and communications, organizations can instill a deep and subconscious trust in their stakeholders.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store