So far there are no new strategies added in the maintenance strategy glossary. However, there are a lot of recent redefinitions for the predictive maintenance. Traditionally, less than 10 years ago, maintenance books and maintenance gurus like Ramesh Gulati and others were saying: ” CBM and PdM maintenance strategies are the same thing in different words”. The condition measurement of the equipment will tell you if the equipment needs maintenance in the near future. That’s what prediction meant at that time.

Usually the workplace adopt one or more of the condition measurement techniques. Example are the vibration measurement, the ultrasonic measurement and Infrared imaging beside oil analysis and many others. Then the PdM team compares the results to a reference value to give a trigger signal for this equipment maintenance.

Nowadays in the digitally advanced workplaces there is a lot of data flowing to the servers. Then the storylines started to show different meaning for the PdM.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Advancement in Predictive maintenance strategy

Actually this started somewhat earlier. It started with the first technician who used a screwdriver or a metal bar to listen to a bearing condition and conclude that it needs replacement. Then along the years service companies developed portable tools that would measure vibration, ultrasound, capture infrared images and so on. At first they were just devices to collect data. This data would be loaded to a software app to draw a trend from the collected data. Then the expert will draw a conclusion about the equipment condition out of these curves.

Later on, appeared the handheld devices which were referred to as an expert system. This naming originated from the fact that it sets an alert based on the experience used in its design. These expert opinions were usually coming from the data sets recorded along many years by the service companies who were early offering periodic PdM services. The tech companies bought the data, information and knowledge base owned by those companies which were their true assets. And they incorporated it in their PdM expert devices and systems.

After that IIoT started to be commercially and technically available and this was the base of Industry 4.0. IIoT is the Industrial Internet of Things that emerged from the original IoT – Internet of Things-. But this time the IIoT was of industrial grade i.e. guarantees safe operations. Commercial and technical feasibility are on another side of the story that we shall delve in later in this article.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

New maintenance strategies need financial and technical support

In the early beginnings of a technology revolution, big firms has the capacity to invest in those emerging technologies. The success of this trial would add to their greatness and the failure of such a trial won’t diminish it. The capacity to invest means a financial budget dedicated for research and development. It also means that there is a team dedicated for the new projects. And of course there are a lot of production units to select a suitable one for the trial. Suitability means facility status, available stoppages for the installation and so on. In smaller or medium size institutions, the team is most of the time busy. Moreover, the budget and budget auditing are so tight to withstand new projects with average success probabilities.

This usually puts the big firms in the leading position when it comes to adopting new technologies. Then after the new technology is proven and there are some success stories, the next level of companies start to think about implementing this new technology. There is another side to the story. The new equipment that uses this new technology are not till now produced at scale. For the early trials manufacturers use custom made equipment. This means that their cost is higher than when they become a shelf product. Later on, many suppliers compete to provide this technology-advanced product at competing prices. They even develop diverse options to suit different use scenarios.

LOWEST-PRICE-24F-01M

How Predictive maintenance strategy benefited from IIoT and Industry 4.0?

At its beginning IIoT started to redefine the predictive maintenance which was simply at that time another name of the condition based maintenance. When the IIoT devices became available, the PdM practitioners reduced the daily tour to collect data. Permanent sensors are now installed on the equipment. And at any moment they are ready to send an alert when the measurement crosses the threshold. This alert might go directly via a sim card installed on the sensor or via the system as a direct message to the PdM team. Then the team will go for a deeper level of measurement, analysis and planning a corrective action.

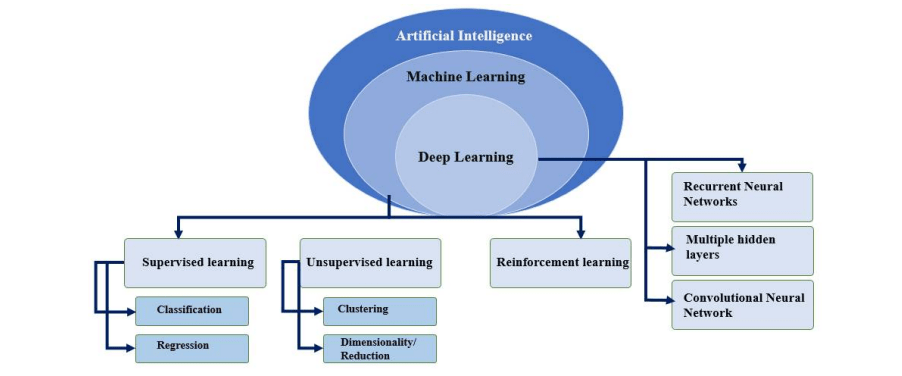

The next level of PdM maintenance strategy developed by Industry 4.0 depends on the possibility to continuously receive real-time data. And instantly store it, analyze it and quickly go through a lengthy pattern recognition to find the trends in the data. That’s what opened the door for real AI based applications in the industrial field.

Simply, the machine learning algorithm behind the AI agent which proposes the decision will learn your normal data’s behavior with time. Then with the fresh data received they identify deviation in real-time. To know better what is AI and its relation to machine learning, you can read more here: The Future of Maintenance – Part 5-2, What AI really is?

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Predictive Maintenance in the context of Industry 4.0 is the maintenance strategy that takes advantage of the huge amounts of real-time and historical data in the enterprise ecosystem in order to detect early anomalies in equipment behaviors, to predict the future health state of the equipment and potential future failure modes and to formulate proactively maintenance plans with the aim to eliminate or mitigate the impact of the predicted failures

Predictive Maintenance in the 4th Industrial Revolution: Benefits, Business

Opportunities and Managerial Implications

The real value comes from analyzing real-time digital data streams from equipment and alerting manufacturers to impending faults that humans can’t see. This happens by analyzing patterns from many indicators. These could be vibration indicators, or product quality starting to reach the boundaries of acceptable quality. By spotting problems early we significantly reduce, down time and maintenance costs because we can solve problems before they occur. This justifies the cost of digitization.

Cost Justification for the digitization project

Siemens Financial Services, Christian Foltyn says: But technology does not always behave in the way that we expect it to. So, unexpected faults or failures not caught by the pre-determined maintenance schedule can surprise manufacturers with potentially massive unexpected costs. Costs not only relating to fixing or even replacing the faulty equipment but also of having a machine out of action for days or weeks.

The benefits of Industry 4.0, Part 1 – Predictive Maintenance

The cost of the digitization project comes from the need to use the most recent advancement in intelligently connected production devices and sensors, and autonomous intelligent monitoring, control, sensing, and diagnostic systems. Together we call them “cyber-physical systems (CPS)” intended to meet human needs.

Collecting, processing, and analyzing real-time Big Data from cyber-physical systems is a strategic phase for the intelligent transformation of the maintenance function, especially with respect to failure prediction, planning, and risk management. This is done through the planning and optimization of interventions using artificial intelligence tools and techniques such as machine learning and deep learning or through statistical models and approaches based on the data and information collected by the different sensors.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

In Conclusion

Recently Predictive maintenance strategy started to look differently from its long term twin; the condition based maintenance. This diversion started with the implementation of the IIoT and was entrenched more with the tools provided by the Industry 4.0.

Even though adopting predictive maintenance in an industrial context is inevitable, it is surrounded by challenges that hinder the application and collective adoption of this smart maintenance approach.

Predictive maintenance algorithms are already available but companies that want to benefit from Industry 4.0 still have to trade off the opportunities of new predictive maintenance against the capital investement required to purchase necessary instrumentations, software, and expertise.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store