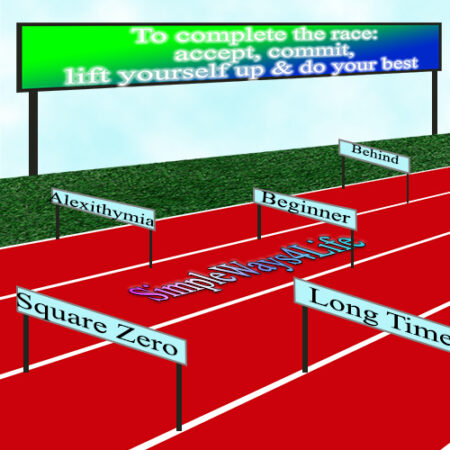

Now after setting the proper mindset in the past couple of weeks, what’s next to step up to the future of Maintenance? We need to be aware of where the industry is heading. That’s what maintenance will end up adopting. But this time Why not we take a step ahead in maintenance? Like this we shall be ready to meet the industry evolution not just try to follow up.

How is our mindset tuned so far?

So far we know that the timeline is moving forward and currently speeding up. The digitization trends are booming and some organizations are getting good return on the investment in this track. When anything is coupled to the digital collection and processing of data it grows exponentially with time. It is turning to be easier, trustworthy and consuming less cost on the long run. As we step out of this track, the gap between where we stopped followıng up and now is constantly widening. That’s why it might look that we are moving backwards. Knowing how the world looks now and anticipating how it is going to be tomorrow makes us ready to ride on and surf again with the flow.

BESTPRICEENDS-11FEB

Being updated with how the world looks like and how it is changing is the bare minimum. You may not follow every trend or adopt every new idea. But at least you know what’s going on out there. Also, let’s not reject the new technological trends because later on it might be a mainstream that we need to deal with. Or, at least deal with people who believes in it like the case of ChatGPT.

Being ahead of the crowd by knowing, analyzing, and concluding about the new tech gives you a competitive advantage. Even you can be at a better position if you are flexible and open minded. This allows you to accept tomorrow what you rejected today due to lack of information or unclear vision. Time might show you that you were wrong or right about your decision. Simply, do not brag that you were correct or fight to prove true a wrong position that you had taken one day.

Maintenance evolves to support the industry evolvement

We shall track the industry evolution and relate it to the maintenance evolution. This will allow us get the theme of the relation between industry and maintenance. The History of industry was divided into 4 revolutions. A revolution is a forcible overthrow of a system in favor of a newer system. Industry Zero or the era before the industry revolution the source of energy for the industry was coming from human forces or animal forces. This living force was the motivative force for the wheels of the industry. Then the end of the 18th Century marked the birth of the steam power. It was then used to run the wheels of the manufacturing instead of the human or animal forces. This boosted the force available for manufacturing leading to Industrial Revolution #1.

BESTPRICEENDS-11FEB

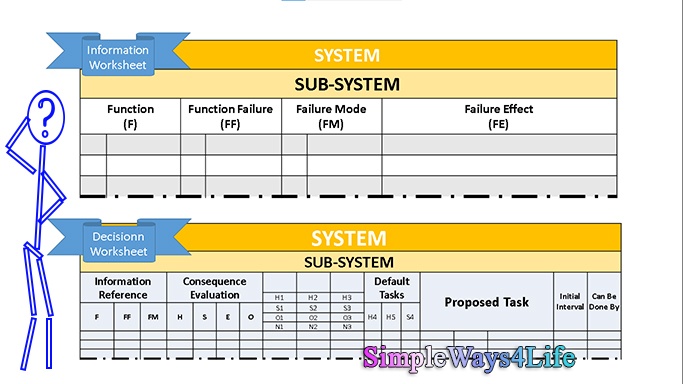

It wasn’t till the 20th century when the electric force replaced the steam energy to drive the industry. This created a more compact but highly productive industrial plants. Here in the Industry Revolution #2 there was some care obout maintaining the equipment productive. Originally maintenance was a side job of the operators. And operators operate it till it fails which doesn’t serve the continuous high volume production required. Also the WWII and the growth in the aviation industry raised the bar for the importance of maintenance. We need to maintain the equipment productive without repaying the cost of a new equipment as maintenance. This was actually when all maintenance strategies and methodologies were invented in the 20th century.

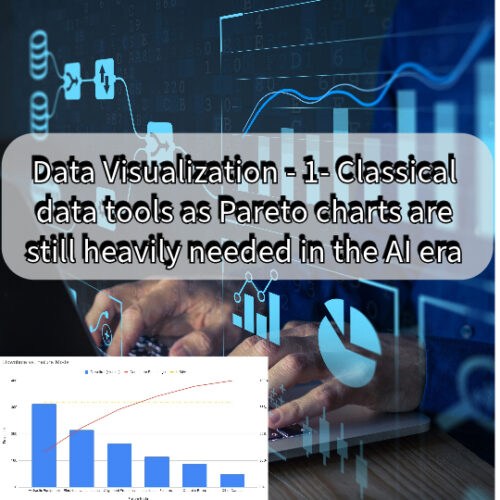

The reality is all about sensors and data analysis.

Then, the Industry Revolution #3 brought automation to the machines and production lines. This increased the throughput and the accuracy at the same time. The PLCs (Programable Logic Controllers) now run the process repeatedly and take critical timely decisions. This was part of the electronics and networking evolution in the second half of the 20th century. Actually globally the software and computing capacity evolved. This gave a chance for Management systems as ERP to exist. Hand-in-hand appeared the CMMS (Computerized Maintenance Management System). CMMS was either a standalone system or supplied as part of the ERP system. The theme of the industry during these days was using software to run and analyze the production process. Same was applied for maintenance.

BESTPRICEENDS-11FEB

BESTPRICEENDS-11FEB

However, the data was manually fed to the system through data entry employees. A position that I am not sure is still available or not. But as usual humanity always has dreams that are yet to fulfill. One of them was the seamless flow of the production information from the machines to the database. And, the flow of decisions back from the Software system to the machines. This is mainly the theme of the Industry Revolution #4. Industry Revolution #4 is said to create cyber-physical environment. This cyber-physical environment will have three pillars: connectivity, intelligence and flexible automation. That’s the only way to create a seamless bidirectional data and decisions flow between the production shop floor and the central cloud based intelligent system overseeing it.

What does Industry 4.0 bring us?

Industry 4.0 brings us digitization of the production process and all related activities. “This facilitates the integration of previously disparate systems and processes through interconnected computer systems across the value and supply chain”: Industry 4.0 in a nutshell by Autonomous Manufacturing. Industry 4.0 is closely coupled to the advancement of certain technologies:

- Industrial Internet of Things IIoT

- Big Data & Analytics

- Cloud and Cloud Computing

- Additive manufacturing (AM) or layered manufacturing by 3D printing

- Robotics and Advanced robotics

- Augmented and virtual reality (AR/VR)

- Cybersecurity Technology

BESTPRICEENDS-11FEB

As we had seen through the evolution of the Industry through successive revolutions, maintenance follows the industry evolvement trend to be an added value for it.

Are we ready in maintenance to encompass those technologies? That’s what we are going to speak about next.

In Conclusion,

Historically maintenance evolves as industry evolves. With every Industrial Revolution, Maintenance tools and strategies grow to provide the needed service for this industrial era. So maintenance had grown from repair it when it fails in slow production environment to time-based preventive maintenance with big production volume. Then the Cost efficiency and the quality needs dictated condition based and predictive maintenance. Then RCM and risk-based maintenance evolved to support the diversified production units. Now what shall we do with the Augmented reality and other technologies Industry 4.0 introduce in the production environment??!

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment