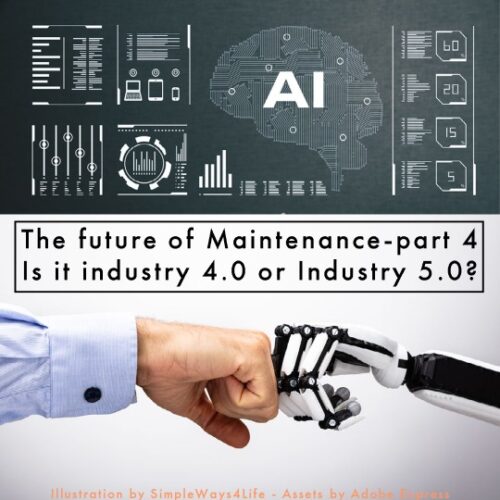

Whichever you will decide to follow its trends, both of them are centered around mastering a set of digital skills. The difference is that in Industry 4.0 human workforce is only supervising the intelligent technology. You can consider Industry 5.0 as an addendum to Industry 4.0. In Industry 5.0 human workforce and robots learn to be collocated. That’s while everyone is doing his part of the job without interfering with each other. In Industry 5.0, the workplace that is packed with robots and automated machinery is safe for human workforce.

How is the industry taking the leap to the future?

To successfully deal with this Intelligent Tech era we need to understand how it thinks. The difference between Intelligent machinery and automated machinery is that the later follows a prescription or a set of fixed steps. While the first -the intelligent machinery- has the opportunity to come up with a new action based on its the external and internal environment. Still it will make a movement in x, y or z direction or a combination of them. But you cannot predict it. It has its built up knowledge in the form of the experiences that it gained from all its previous actions. It has the logic of evaluating each action as appropriate or not. An appropriate action takes it closer to the target. While an inappropriate one takes it away from it while considering all its environmental conditions.

It wouldn’t have been possible to live with intelligent machines and software without having nearly infinite storage of data that is easily accessible. Moreover, this data has its own management sciences. Where you purify and validate data and link it together to draw a coherent picture of your world or the intelligent machine world. Then some algorithms help those intelligent machines pick up the right set of data. Then they process it quickly enough to come up with a conclusion.

How maintenance team can interact with Intelligence in the work place

You can think of it like your accumulated 20years of maintenance experience flashing across your mind when you see a loose bolt in a motor base or a leaking fluid from a pump. You found this incident during a morning inspection tour. Now all the possible reasons for this leaking fluid will flash across your mind. Then you link it with the possibility to switch off this pump for now and move to a standby one. Who will take this action, you, a supervisor, the operator or the control room? Then what action do you need to take for clearing up the mess.

Maybe you have a small handheld through which you can initiate a work request that you will setup its priority based on your experience. Or will you rely on what the system guides you to. Then a complete scenario of the needed repair and the parts and the stoppage time will pop up in your mind with the previous experience of similar incidents.

BESTPRICE-ENDS-04FEB

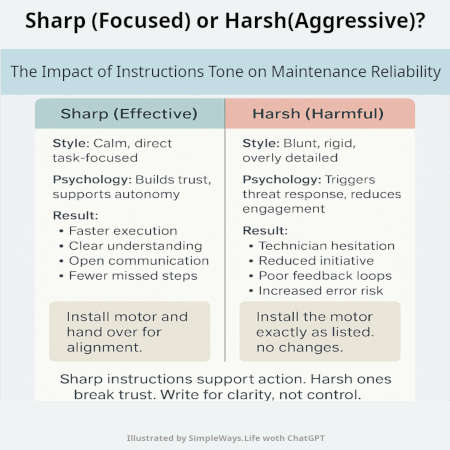

Actually if your handheld is linked to a smart system, it will give you a set of recommendations based on the logged in situation or result of inspection. A smarter system will not bother you with unneeded information. It will just tell you do 1,2,3. Those are the actions related to you now. Then it will convey the message to all other concerned.

Same smart system in case that you are now in the process of repairing the leakage will give you the steps to follow. That’s of course after preparing the parts and the safety conditions. The system also tells you the procedures to set the safety conditions. However it won’t cross check if you followed the procedure or not. It is your deliberate choice.

Why your feedback is important for the industry?

But in case you follow your own steps not the ones in the procedures you are missing the opportunity to rely on and trust the system. Moreover, you are not helping your team members who will try to follow the system steps when you are engaged in another activity. On the other side, just ignoring or overlooking the system steps might be risky because you overlook the experience of the one who had written these steps.

Correcting the system procedure to match the reality makes you owning the system. Those system are not set in stone but modifying them might take some steps to ensure that any modification is really needed and not jeopardizing other activities or following steps. The standard procedures already took some valuable engineering time. So modifying them would need some valuable human thinking about the subject.

How to relate machine Intelligence to the industry? ABC of AI

Since, I got a chance to program some simple AI applications. Let’s speak how it looks like to create an AI player for some games. An AI player is simply an AI agent. The Agent in the AI world can be anything that perceive its environment through sensors and act upon that environment through actuators. An Agent runs in the cycle of perceiving, thinking, and acting. The difference between an agent in the software world and an agent in the physical world is in the type of sensors and actuators used.

In the physical world the Agent perceives its environment through sensors as camera, proximity, weight, position, distance, flow, pressure and so on. Actuators in the physical worlds are valves and motors. Those valves and motors turn wheels and move cylinders. They also increase or decrease or change the direction of the flow of some fluids. However in the software AI Agents, Inputs and outputs are limited to those received through keystrokes, screen input or output, files reading or other input or output devices connected to the handheld smart device like a speaker a vibrator or a light indicator.

Usually the critical point is in the trigger of such perceiving, thinking, and acting cycle. That we covered in secrets of a maintenance training program linked below:

BESTPRICE-ENDS-04FEB

In Conclusion,

As we had said before, maintenance follows the industry trends. Whether you are thinking of Industry 4.0 or Industry 5.0 as the current industry trends both of then relies on Intelligence of the machines. An Intelligent machine can sense its environment, take a decision and apply an action or give a recommendation. How this will transform our maintenance activities, let’s continue in next articles.

2 Comments