Materials management is important on the personal level as well as the organizational level. To reach maturity in the materials management you need to minimize stock outs, maximize service level increase inventory turns per year for the consumable parts as far as possible. As far as possible is a flexible word but very important because it gives you a margin to tune in to the best practices. e.g. If the best practices says that to reach maturity of your material management, you need to reach 2 inventory turns per year. However, the material supply chain as planned on the organization level do not support this idea because it increases number of low value orders. In other words, 80% of the supply chain work is around orders that are within 20% from the yearly cost. This means that you need to come up with your own best practices and maturity levels.

If you manage to understand it on the personal level, you would be able to apply it globally. Let’s take a basic example from this story about purchasing coffee filters.

The life cycle of your coffee filters

One day you woke up and didn’t find a new filter for your coffee machine. You turned your kitchen into a mess looking for a last filter out there. You start waking up other family members and claiming them that they had moved it from the position you were used to. Then, you were slammed by a reply that the last filter was used a day before. This increased your frustration. Why who used the last one didn’t order a new set? They did, but it will be delivered today within the day. OK, you will take your coffee on the way.

Next day in the morning you found your filter packet. Ops, it is not fitting in the machine. Then you are now depressed. Why, you made the order for wrong filters. I made the order for the cheapest set as usual. I was in a hurry so I didn’t look for the size and grain match. Here, you gained two pieces of information, Your coffee machines filers are not standard. And, they are not the cheapest anymore. So, for the second day you started your daily commute without the coffee injection into your blood.

This day you decided to get 2 filter packets. It was at a higher price but you compared it to the frustration of not having your coffee in the morning, you accept it. You placed one in the coffee closet. The second one you hide it a secret location. While you were on a 2 day business trip, the coffee filter packet on the public inventory ran out. So someone got a double packet offer. placed one in the coffee closet and the other one in his books closet for the next time he face a shortage.

The end of the story

One day while moving things around at home we found five or six coffee filter packets stored in strange locations and some of them not fit for use anymore.

This story is not far from what happens in our maintenance spares and material stores

Materials Management Maturity

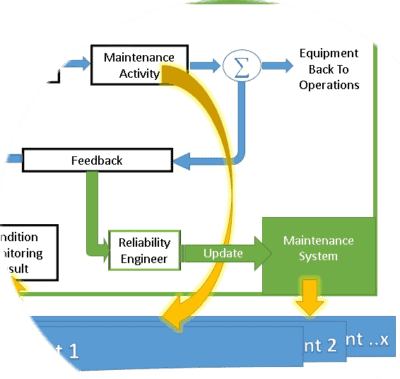

As we agreed before, to grow mature in any area of life or business we need to disintegrate the overall target into different tracks and each track to have its own target and milestones. interdependency between the different tracks will create the overall schedule for our maturity journey. SO, our starting point is to understand the lifecycle of the spare parts or other material as greasing.

The first station, What do we need to keep as spares and why?

That’s a classical start point which we had stressed on in our trainings. Knowing your equipment is a crucial starting point for reforming the maintenance performance. You can find links to our discounted trainings below:

Usually, you need to start by a list of your equipment. Then you organize them by the production line, by sites or by type, for controlling the spare, you need to group them by type, and model. After that, you need to list down the main parts that you need as spares and their usage cycle. Why/ Because handling the ordering for materials needed weekly differ from handling the materials needed for the capital repairs every few years.

Then comes the dilemma of components vs whole parts

By default, in the maintenance manuals you will find the subassembly parts list. So when you list down and set the specification, will you code in the register the main assembly and all its internal parts; If you can, from effort and time point of view, it would be great. However, what you need to purchase? Will you get the complete assembly only? Will you purchase every element of the assembly? There are few questions here that you need to ask to reach a conclusion:

- What is easier to replace? The whole part or its internal components. In other words, can I repair the complete assembly in place without removing it completely?

- Can we specify in enough details the internal parts and the whole assembly?

- Does my team have the experience to dismantle the complete assembly, repair or replace an internal part on site and tune the equipment correctly back to operations?

- Can I know which internal parts I need to keep in stock?

- If I have the complete assembly can I dismantle some internal parts and use them to repair the assembly on the production line?

- When comparing each alternative from the above we need to keep in mind the following

- Time for each action till restoring the equipment in operation

- Cost of each alternative

- Technical ability of my team

- Availability of subcontractors for repair if needed

- Are the internal parts sold separately?

- Who is in charge of repairing the spare whole assembly after that?

- Store transactions for the subassembly parts

- Financial costing for the repair of the installed assembly and the repaired one? internal parts and manpower cost

What are the stock problems caused by wrong selection of the parts to be supplied?

Mainly, regardless of the level of inventory, we face stock outs and delay in jobs start due to parts. Moreover, a lot of local, private, hidden stores are generated from repaired, under repair or just in case we needed it assemblies and internal parts. The audit or inspection rounds is complaining about the pilot stores and the condition of the equipment piled in them.

The warehouse or store is suffering due to many reasons. The inspection area is expanding and contains a lot of rejected items due to many reasons. There are uncomplete parts on the shelves that can’t be used and are not repaired by the relevant team. There are costing problem between the warehouse and the financial team due to the repeated movement of the same part from the store to the production line and back again without remarks or comments.

Some solutions to materials control:

The first solution to any problem is to admit that there is a problem. So if you have any of the above symptoms then you need to think of corrective actions.

Second, plan some effort i.e. manhours to solve the problem.

Third the problem can’t be solved from the level of the problem. In other words, don’t keep doing the same actions that caused the problem while trying to clear the history of the problem.

Fourth, start by monitoring the sources of the problem and work on eliminating them. e.g. the next assembly removed from the production line on a hope to repair need either to be immediately scheduled for repair or discarded. If it needs material to be purchased, why this material is not purchased before hand? Is the repair feasible? Is it convenient to use it again after repair? are there similar parts in the stashed stock and no one is using them? Why?

Fifth, put the recommendations into action. Order one of the older repaired items to be installed in a coming repair. If it fails or not suitable, scrap it. And, stop the practice of putting all removed parts under repair. Or, send it to a qualified vendor to refurbish it. Then asses the feasibility of this solution.

Sixth, review the description and improve the visibility of the parts available at all locations to all of the maintenance staff.

Seventh, review the part list or our internal catalogues that we use to make requests to the supply chain. Some parts are already obsolete and others are not even there or their technical description doesn’t allow proper ordering or noticing by the team.

Eighth, review the maintenance and store procedures. Some gaps or unrealistic steps might be creating and exploiting the problem.

Secondly, The scope of each team in the materials supply cycle. This will be in the coming chat.

In Conclusion,

There is no maintenance without materials whether spare parts or consumables. The absence of any needed part will diminish the other great efforts done by the maintenance team. That’s because the target of maintenance is to keep the equipment in healthy productive condition. If this target is missed due to missing or wrong parts can’t be justified by any other effort done.

One of the missed gems is that we forget to question and tune the basic stuff. So if our parts catalogue is not complete with the data needed to order and the cycle of use, then some items will be wrongly delivered and others won’t be delivered at all. After few years, these parts and subassemblies lists and details need revise. Some equipment are gone for good while their spares still lay there. Other parts, were replaced with other versions or modified models while the original parts that are not needed any more are still in the records or on the shelves.

The 14 questions and the 8 recommendations listed here will guide you through the first step of maturity in materials management.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store