Maintenance is often perceived as a routine task—something necessary to keep operations running but rarely seen as a strategic powerhouse. Yet, in the evolving world of modern maintenance, there’s a shift happening—one that calls for awareness, foresight, and strategic thinking. This is the foundation of Conscious Maintenance, a transformation approach that goes beyond checklists and reactive fixes.

BESTPRICEENDS-11FEB

In my training programs—Secrets of Building a Maintenance Program, which blends practical AI usage on an individual level, and Reliability Mindset Training, which transcends typical reliability practices to reveal the true essence of reliability—we delve deep into strategic and mindset shifts needed for effective maintenance. This article builds on those ideas and aligns with our previous explorations of AI’s role in maintenance and the art of conscious maintenance. Today, we’ll explore how embracing this approach can empower your foresight and drive long-term success.

BESTPRICEENDS-11FEB

Consciousness Bridges Knowledge, Strategy, and Success in Maintenance

Consciousness is the vital link that connects technical knowledge, strategic planning, and long-term success in maintenance. Knowledge alone—whether about equipment behavior, maintenance techniques, or technological tools—provides a solid foundation, but it’s the conscious application of this knowledge that drives meaningful results. When teams cultivate an acute awareness of their operational environment, they begin to see beyond immediate tasks and recognize how every decision impacts overall performance and business goals.

This bridge between knowledge and strategy becomes even stronger when consciousness fuels a proactive mindset. Instead of merely following routine schedules and getting punched by breakdowns, conscious maintenance practitioners use their insights to shape data-driven strategies. They anticipate potential failures, prioritize critical assets, and optimize maintenance activities for maximum efficiency. This approach not only reduces downtime but also minimizes costs and enhances the reliability of the entire system.

Moreover, the role of consciousness extends into fostering a culture of accountability and innovation. Teams that are aware of the bigger picture are more likely to collaborate, share insights, and propose improvements. They understand how their individual efforts contribute to long-term success and take ownership of maintenance outcomes. This shift from task-based work to strategic thinking empowers maintenance teams to evolve into key drivers of organizational excellence.

What Is Conscious Maintenance and Why Does It Matter?

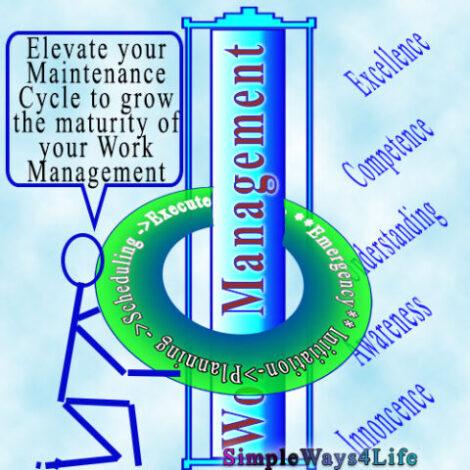

Conscious Maintenance is an elevated approach where awareness, strategic insight, and proactive thinking become central to maintenance practices. It’s about moving from reactive responses to anticipating and preventing issues before they arise. By fostering a culture of continuous improvement and foresight, maintenance teams can transform their roles from problem-solvers to strategic enablers of success.

Ready to transform your mindset? Click and Get your copy > Now For Sale on Simpleways.life & Amazon

The Role of Awareness in Elevating Maintenance Practices

Awareness is the cornerstone of conscious maintenance. This means developing a deep understanding of your equipment’s behavior, operational conditions, and potential failure modes. When teams cultivate this awareness, they notice early signs of wear, identify inefficiencies, and prevent costly breakdowns before they happen. This proactive stance reduces downtime and increases equipment longevity.

Strategic Thinking: The Key to Long-Term Success

Strategic thinking in maintenance requires a shift from day-to-day fixes to long-term planning. It involves setting clear maintenance objectives, aligning them with business goals, and using data-driven insights to prioritize actions. By integrating AI tools, like those covered in our Secrets of Building a Maintenance Program training, teams can predict failures, optimize schedules, and make informed decisions with greater accuracy.

BESTPRICEENDS-11FEB

How Conscious Maintenance Enhances Reliability

Our Reliability Mindset Training focuses on transcending traditional reliability practices by emphasizing strategic foresight and virtual plant applications. Conscious maintenance aligns perfectly with this mindset, offering a holistic approach to reliability. By understanding the bigger picture and implementing forward-thinking strategies, teams can ensure consistent performance and avoid unexpected failures.

BESTPRICEENDS-11FEB

Practical Steps to Implement Conscious Maintenance

Cultivate Awareness:

Train Teams to Recognize Early Warning Signs and Monitor Key Performance Indicators

Awareness is the foundation of conscious maintenance. It means developing a deep understanding of equipment behavior, failure patterns, and performance metrics. Teams must learn to spot subtle shifts in data, unusual sounds, vibrations, or temperature changes that signal potential issues.

Practical Application: You can start by setting up a training program on condition monitoring and data interpretation. Use historical failure data to show real-world examples of early warning signs. Establish key performance indicators (KPIs) like Mean Time Between Failures (MTBF) or Overall Equipment Effectiveness (OEE), and ensure teams regularly review these metrics to spot trends.

Adopt Predictive Maintenance:

Use Predictive Tools to Anticipate Failures and Optimize Maintenance Schedules. You will find most of them AI-Driven nowadays

Predictive maintenance leverages data analytics to foresee equipment failures before they occur. By analyzing historical data and real-time inputs, predictive tools identify patterns that help maintenance teams address issues proactively.

Practical Application: Start small by applying predictive models to your most critical assets. Further more you can use machine learning tools to predict failure likelihood – as we learnt together here: The Road Ahead for ML in Maintenance -. And schedule maintenance activities based on data-driven insights, reducing downtime and maintenance costs. Finally, Implement AI-driven maintenance software that integrates with your existing systems – when possible.

Align with Business Goals:

Ensure Maintenance Strategies Support Broader Organizational Objectives

Conscious maintenance goes beyond keeping machines running—it aligns maintenance efforts with business success. This means understanding how maintenance impacts production efficiency, customer satisfaction, and profitability.

Practical Application: Collaborate with leadership to define maintenance goals that support overall business objectives. For example, if the goal is to increase production capacity, focus on preventive measures that minimize unexpected breakdowns. Use metrics that reflect business impact, such as cost savings from reduced downtime.

Encourage Continuous Learning:

Foster a Culture of Knowledge-Sharing and Skill Development

Maintenance practices evolve, and staying ahead requires a commitment to continuous learning. Encouraging teams to share insights and stay updated on industry trends enhances collective expertise.

Practical Application: Create regular knowledge-sharing sessions where teams discuss equipment performance, challenges, and solutions. Invest in training programs on advanced maintenance techniques and emerging technologies like AI and IoT. Support certification programs to enhance individual skills and boost team capability.

Conclusion: Embrace the Power of Conscious Maintenance

Conscious maintenance isn’t just a methodology—it’s a mindset shift that transforms maintenance from a cost center to a strategic asset. By empowering your teams with awareness and strategic insight, you unlock foresight, prevent failures, and drive unparalleled success.

Ready to take your maintenance practices to the next level? Explore our training programs and join a community dedicated to innovation and reliability.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store