Actually when you are looking from a distance, power transformers are thought of as the most reliable equipment around us. You might get more confident if you work closer to them and see the amount of care given in their design, manufacturing, onboard equipment and maintenance. However, still some transformers fail under certain conditions. Some of those failures are related to design; Others are related to usage. Unfortunately, some failures are induced by maintenance or or its auxiliary equipment.

Not every work place has visible power transformers to care about. Even though, surely, some sort of transformers are integrated within every equipment.

So, it would be an eye-opening to chat about transformers and make some analogies with maintenance, work and life.

The prime analogy; transformation

The basic concept of transformers is to transfer electrical power through magnetic coupling or induction between 2 coils without direct contact or continuity. In other words, The electric power in the form of voltage and current is flowing through a coil. Nearly, The same amount of electric power is available with different voltage and current at the terminals of another coil. This secondary coil is totally electrically isolated from the first one. Only the magnetic induction from one coil to the other is transferring this amount of power. For those who are not from an electrical background, an old incandescent💡lamp was consuming 100 watts. This 100watt is roughly equal to 100VA i.e. 100VoltxAmpere as it is nearly pure resistive. Main Electric Substations house 500,000,000VA transformers that powers complete cities.

Regardless if it is a 500 watt transformation or a 500 Million Watt, it used the same concept of magnetic induction between 2 coils.

A little bit more from the electric knowledge about transformers. The electric voltage is transferred in proportion to ratio of the number of turns between the primary and secondary coils or what we call winding. The current available for usage at the secondary terminals is in inverse proportion to the current in the primary winding to keep the same power i.e. Volt x Ampere

Another important fact is that the transformer’s primary and secondary windings arrangement is around a ferrite core to ensure maximum magnetic field transfer and to minimize loses. Moreover, transformer coils and windings are firmly fixed to the base of the transformer housing. Any lead wires for inputs or outputs are secured so even when vibrate (they do) there is no friction against a surface that would damage them with time.

How this transformer model would explain a human model?

First, we can tune the power that we give to any topic. We have physical First, we can tune the power that we give to any topic. We have physical power and mental power. You can compare this with voltage and current. You will supply the subject in your focus with the needful power. But, would you put the highest possible voltage i.e. physical power? You might break it. As if you you were triggering a failure when you supply voltage higher than rated. Or, you might break the insulation of that device.

Second, we can transform the power we have into a useful form. You have a set of resources in the form of manpower and tools. How can you transform them into task execution within certain time?

Third, the energy of a person, a situation or a place we are colocated with is transferred to us. Regardless of how centered you are with the situation, you receive some magnetic field induction. So, we need to avoid denying this fact. Instead, We might better improve our shielding and grounding.

Fourth, the type of transformation.

Transformers have a lot of types based on their usage. There are step-up and step-down transformers regarding the voltage applied to the primary winding and that received at the secondary. So, some people faces a problem and amplifies it while giving little flow of current or Ampere to the solution. Like a step up transformer, it amplifies the voltage but gives little current to flow. They are useful for long distance transmission But you need to step-down the voltage and give more Ampere or current to actions when you reach the destination. Others tend to decrease the potential of the problem and focus on supplying more current or Ampere to the solution. They behave like a step-down transformers.

Some transformers are only for measuring. They take either a current or voltage sample to indicate how things are running. Although they don’t consume power but they make needful actions. They are crucial for protection and calculations. Many people and tools in our life are like this. You don’t see a huge influence of their existence in our everyday life. However, their absence risks our existence.

Fifth, transformer loading.

Think a transformer you got to supply you with 100KVA. It is not supposed to be working continuously at the rated 100KVA. This weakens it’s ability to withstand overloading. I will leave you a link to Schneider answer for a question “What is the permissible overload percent for oil-immersed transformers?” The answer includes a table which doesn’t even show the 100% loading. It shows a maximum of 90% continuous loading. In this case, you can allow the transformer to be loaded to maximum of 110% for 60min.

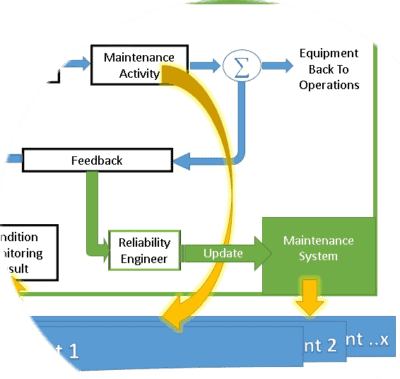

The cUsually transformers act as an intermediate person. They transfer the power to a usable form to serve a function that we need. The transformer itself is not the end target or the end product that we want. However they are a bottle neck for any working place. Losing a transformer or taking it out for repair means a total loss of production. Even scheduled maintenance activities other than cleaning and oil sampling take a considerable production stoppage time.

That’s why in Schneider’s answer they speak of a normal situation of loading the transformer continuously for 50%. Then guess what, you can allow it to be overloaded for 150% for a max of 15min??¡¡ Usually it is better to have this overload margin in a transformer so the loads it supplies can overcome the peak that occured in one machine or till this faulty load is stopped. That’s better than losing the complete power supply to the building or the production facility. Then, trying to retrieve the normal operation. Condition is worse with a dry type transformer I.e. not enclosed in oil tank to cool it’s copper windings, you will find the link also at the end.

So, how this is related to life loads?

Now, for humans and machinery tools, near 100% continuous loading Now, for humans and machinery, near 100% continuous loading has its risks. Because, any overloading due to environmental business or life conditions is risky. It might end up in a breakage, outage, failure or complete loss. Utilize the capacity you have moderately, leave a margin to withstand unavoidable overloads from life or work . Stay safe.

Schneider links

- What is the permissible overload percent for oil-immersed transformers?

- What is the permissible overload percent for dry type transformers?

- Noe: Loading Schneider website for first time will take you to home page, so load the link again.

In Conclusion,

We tend to design machinery and understand the natural phenomena based on the understandings and believes we have. That’s why it is easy to correlate our observation on the machinery to ourselves and even to the other machinery and tools we use. This applies also for the soft and digital tools we have. So, as you use the transformer to transform electrical power to useful levels of volt and current, do this with your innate physical and mental power. Avoid continuous loading to leave a margin for the unavoidable overloads. Craft your life and career with the same care given to the transformers design. Stay safe.