In the world of industrial maintenance, we often hear about complex, expensive AI solutions implemented by large organizations. But what if the real revolution is happening right in front of us – at the individual practitioner’s level? Imagine transforming your maintenance approach using free, accessible AI tools that are just a click away.

Today’s maintenance professionals are no longer bound by traditional limitations. With freely available AI technologies, a technician, engineer, or maintenance manager can now:

- Rapidly analyze extensive maintenance documentation

- Predict potential equipment failures

- Generate insights from historical data

- Troubleshoot complex mechanical issues more efficiently

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

These aren’t futuristic fantasies – they’re practical realities accessible to anyone willing to learn and experiment. Whether you’re working in a small workshop or a large industrial plant, AI can become your personal maintenance assistant, amplifying your expertise and helping you work smarter, not harder. That’s part of what we covered in Secrets of Maintenance Program on Udemy offered in English and Arabic and loaded with real hands-on examples, downloadable running software and more.

AI-Powered Document Intelligence

This helps you revolutionizing Maintenance Information Retrieval. In the complex world of maintenance, professionals are often overwhelmed by massive technical manuals, repair guides, and equipment documentation. AI document upload and analysis tools offer a game-changing solution: instant, precise information extraction.

Key Capabilities:

- Rapid scanning of hundreds of pages in seconds

- Extracting specific technical details like part numbers, troubleshooting steps

- Locating dealer contacts and maintenance schedules

- Summarizing complex technical documentation

- Cross-referencing information across multiple documents

from 24 FEb to 01Mar:

Practical Applications:

- Quickly find repair procedures for specific machine components

- Identify exact replacement parts without manual searching

- Extract maintenance history and recommended service intervals

- Analyze technical specifications across different equipment manuals

Comprehensive Hands-On Training:

While this overview provides a glimpse into AI document analysis, my course “Maintenance Program Secrets” offers detailed, practical training on implementing these techniques in your daily maintenance workflow.

Advanced Technique Preview:

For those seeking deeper technical integration, advanced approaches like creating Google Cloud projects with AI document processing services offer even more sophisticated document intelligence capabilities. But due to its sophistication I can help you with establishing such a project as part of consultancy service -Link here or at the end of the chat –

Want to transform how you interact with technical documentation? Your AI maintenance assistant is ready to help.

Turning Data into Maintenance Strategy: The Art of Intelligent Analysis

In the industrial jungle of maintenance, data flows like a complex river—wild, unpredictable, and potentially transformative. But raw data is just noise without the right interpretative lens.

Imagine walking into a maintenance workshop with mountains of historical records, breakdown logs, and performance metrics. Traditional approaches would have you drowning in spreadsheets, desperately seeking patterns. Enter AI: your digital analytical companion, but not your master.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

The Real Power of Analysis:

Maintenance isn’t about collecting data—it’s about extracting strategic narratives. Tools like Pareto analysis aren’t just mathematical tricks; they’re strategic x-ray machines revealing where 20% of your efforts can solve 80% of your problems. A time series doesn’t just show numbers changing—it tells a story of equipment evolution, predicting potential failures before they whisper their first warning.

The AI Assistance Paradox:

- AI generates insights at lightning speed

- BUT: Context is king, and you wear the crown

- Recommendations are suggestions, not commandments

- Your operational knowledge transforms data into wisdom

The Risk of Blind Trust:

Every AI model comes with a disclaimer: “Verify before acting.” Why? Because an algorithm trained on generalized data can’t understand the unique heartbeat of your specific machinery, your unique operational ecosystem.

A Risk Matrix isn’t just about color-coding potential failures—it’s about understanding the intricate dance between probability and impact. AI can help you choreograph this dance, but you must lead.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Course Promise:

“Maintenance Program Secrets” doesn’t just teach you to use tools—it transforms you into a data strategist. We don’t just show you how to read the map; we teach you to navigate the terrain.

Warning: In the world of maintenance, AI is your scout, not your general. The battle plan? That’s always yours.

Predictive Maintenance: Turning Historical Data into Proactive Insights

Predictive maintenance transforms reactive repair approaches into strategic foresight. By leveraging machine learning libraries in Google Colab, maintenance professionals can train models to predict equipment health with remarkable precision.

Key ML Capabilities:

- Train models on historical performance data

- Predict equipment failure probabilities

- Generate health percentage assessments

- Identify potential maintenance needs before critical failure

Practical Learning Approach:

Our course provides ready-to-use Colab notebooks that allow you to:

- Upload your equipment performance data

- Apply pre-configured ML algorithms

- Instantly generate predictive insights

- Understand machine learning principles without deep coding expertise

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

The Power of Predictive Modeling:

- Not just numbers, but actionable intelligence

- Reduce unexpected downtime

- Optimize maintenance scheduling

- Minimize repair costs

Course Highlight:

“Maintenance Program Secrets” delivers executable Colab code, enabling you to implement predictive maintenance strategies immediately.

Warning: ML predictions are probabilistic. Always combine algorithmic insights with expert human judgment.

Machine Learning Evolution: From Regression to Generative AI

Regression models represent the foundational architecture of modern machine learning. These statistical approaches predict continuous outcomes by understanding relationships between variables. Regression models predict continuous numerical outcomes by understanding relationships between variables.

Core Regression Models:

Linear Regression: It works best for linear, predictable relationships, it is the simplest model as it predicts outcome via straight line relationship. Linear Regression Fundamental Equation: y = mx + b where

- y: Predicted output

- x: Input variable – what we measure at field

- m: Slope (coefficient) or simply the rate of change output relative to input

- b: Y-intercept – in other words, what is y when x is zero. Just imagine that you measure vibration of a stopped pump. It gets you the background vibration from the nearby motors and structures that might worsen the pump condition

To capture complex relationships we use Multi-Linear Regression: y = b0 + b1x1 + b2x2 + … + bnxn, where there is multiple input variables and, each variable has its own coefficient

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

In maintenance, regression models initially helped predict:

- Equipment failure timing

- Performance degradation rates

- Maintenance interval optimization

More complex model analysis

Polynomial Regression handles non-linear relationships using curved line to map complex patterns. It is more flexible than linear regression

Logistic Regression predicts probability of binary outcomes. It is used for classification problems.

As computational power expanded, these regression techniques evolved into more sophisticated generative models. These advanced algorithms don’t just predict—they can:

- Generate synthetic training data

- Simulate complex equipment behavior patterns

- Create predictive scenarios based on historical performance

This progression demonstrates how maintenance professionals can transform raw historical data into intelligent, forward-looking insights.

Concluding Insights:

Our exploration revealed three critical AI-powered maintenance strategies:

- Document Intelligence: Rapidly extracting crucial information from complex technical manuals

- Strategic Data Analysis: Using AI to accelerate and enhance analytical processes

- Predictive Maintenance: Leveraging machine learning for proactive equipment management

“Maintenance Program Secrets” provides the comprehensive toolkit to implement these strategies, bridging the gap between traditional maintenance approaches and cutting-edge AI technologies.

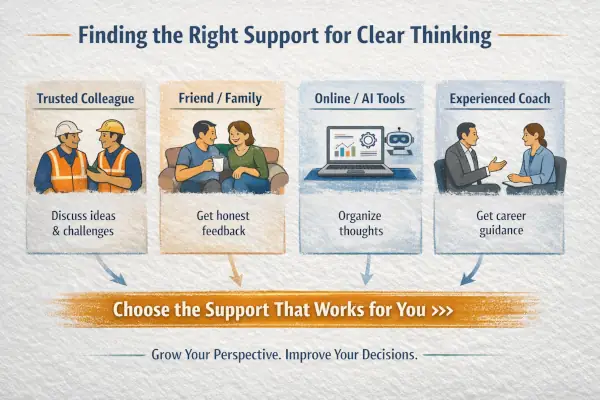

The future of maintenance isn’t about replacing human expertise—it’s about amplifying it. That why AI is your assistant.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment

Comments are closed.