Sure, that’s the normal status for any failure. But first, we need to be confident of our understanding for the failure modes and its importance. There is nothing worse than using an expression like Failure Mode while we don’t have a correct perception of its meaning in our imagination. That’s what we shall go through today with examples.

What is a Mode?

Literal definition of a mode is: ” a way or manner in which something occurs or is experienced, expressed, or done..” e.g. “My preferred mode of transport is a bicycle”.-Oxford Languages

There is another statistical definition of a mode: “The mode is the value that appears most frequently in a data set. A set of data may have one mode, more than one mode, or no specific mode at all”. In Short if you have a data set: “1,2,2,3,4,4,4,5,6,7,8,8,8,9,0” has two modes of “4” and “8”. However all the number 0 to 9 are members of this set but there is clear tendency of this data set towards 4 & 8. – Investopedia–

What is a failure Mode?

A Failure mode is one of the causes of a function failure. In the beginning we need to retrieve that maintenance main target is to maintain the equipment performing the function it is originally acquired for. When this function is totally or partially lost, that’s what we call a function failure. What caused this loss of function is what we call a failure mode.

There are some deceptions in our view of the failures causes or modes. If a pump stops to deliver the cooling water either partially or totally then the pump failed. However, “Pump Failed”, “Motor tripped”, “Cooling water stopped or decreased” are not failure modes. Those are superficial expression of what happened. The Failure Mode should include a description of a failure cause that was/will be repaired. This draws us to the importance of Failure Modes.

Why Failure Mode is important?

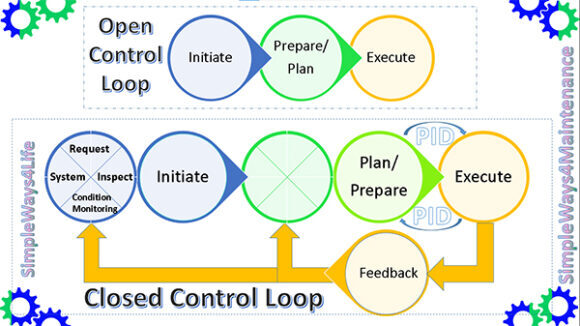

Actually, maintenance is mainly managing the failure modes. When you are performing a reactive maintenance, you are repairing the cause of the failure or the Failure Mode. Moreover, when you are planning your maintenance activities, you are chasing some failure modes to prevent them. When the maintenance team changes a filter based on condition or operation hours, the main target is not to maintain the filter in a good condition. The main target was to maintain the water supply because when the filter gets clogged it will stop the water supply fully or partially.

Same as when consider a motor. The motor doesn’t work in an isolated medium from the other parts of the equipment. So, we don’t chase motor failure modes because it stop its rotation. Those failure modes of the motor ceases some equipment from delivering its intended function. The motor is a part of an equipment that delivers a function. What fails from the point the product point of view is the function of the load that the motor drives. When we have a maintenance activity to check or repair the thermal insulation of the motor power supply cable, the targets of this activity are:

- Maintain the motor in operation i.e. rotating

- Keep the load of the motor performing its function whether a pump or a conveyor

- The ultimate target from repairing the motor cable is to deliver the water or transfer the final product or some needed material over the conveyor

- The better target is to maintain the water Q (flow and pressure) and timely delivery of intermediate product on the conveyor to its destination.

So, why a single functional failure has many failure modes?

Reflect back on our brief explanation above for the functional failure and the detailed explanation we had on our previous chat Operators or Maintainers?. Our main target is to maintain the intended function of the equipment or the production line. This function is produced from a set of individual equipment or parts. If we reimagine a pump or a conveyor, they have their main function of pumping water or transferring material. However, they compose of individual parts. Each part has its own function that serves the equipment.

Let’s see an example, Every equipment has:

- Power supply system

- It starts from a circuit breaker that switches the main electric power ON & OFF. The circuit breaker and its auxiliaries as overload and tripping contacts serves 3 functions:

- It isolates the electric power for safety reasons during maintenance

- Trips OFF to protect the parts after the breaker when an abnormal condition of withdrawing excess electric power i.e. current either suddenly or gradually. I got a personal experience when the setting of a circuit breaker was set higher than the normal operating current. When the impeller of the pump started to stuck and withdraw abnormally high current, the motor continued to rotate and crushed the impeller totally against the casing.

- Isolates the big distribution that serves many machines from getting to a failed status and stopping all the machines. If the circuit breaker of this machine didn’t trip OFF the upper one that serves many machines would trip OFF

- Then cables carries the electric power to the equipment

- There are local power connections and controls within the machine itself

- It starts from a circuit breaker that switches the main electric power ON & OFF. The circuit breaker and its auxiliaries as overload and tripping contacts serves 3 functions:

- The foundation of the pump or the structure of the belt conveyor

- The mechanical parts that rotates, cuts, contains, seals, transfers the product and so on.

- The protection devices whether mechanical, sensors or guards

Surely each part listed after the Circuit breaker has the same level of details but, we skipped them to keep focused. Give your self some time to reflect the same idea on them

Each part or subsystem has its own function, function failure and many failure modes. The causes of each part failure is a failure mode of the equipment as a whole.

How much failure modes are enough?

There are two critical factors for judging. First one, the quality of the failure modes is more important than the number. Second one, the number of failure modes recorded need to be balanced.

1.Quality of recorded Failure Modes

Failure Modes recorded are of high quality or in other words beneficial if they describe a clear probable failure that is within the reach of the maintenance team to repair whether it happened or not.

2.Balanced number of Failure Modes

Too few Failure modes indicates one of two problems. Either the selected equipment is part of a bigger system. Or the failure modes recorded barely touch general failures so no clear actions can be deduced for this failure mode. Like pump impeller jammed or motor failed.

In the coming chat we shall demonstrate failure modes of some sample equipment and some options to properly level your system analysis.

In Conclusion,

The worst thing is when you try to understand a big subject like RCM -Reliability-Centered Maintenance- while you don’t have the correct perception of some of its key terms as Failure Mode. This chat draws a perception of the The Failure Mode, its importance and how to select useful ones.

The Next chat shall bring more examples from various disciplines in the maintenance field. What a bless coffee is, even in your imagination.

One Comment