In the fast-paced world of maintenance engineering, keeping systems up-to-date is crucial for optimal efficiency and reliability. However, the process of upgrading can seem daunting, especially for those working with limited resources. This article explores a step-by-step roadmap on how to revamp a maintenance system using basic tools and free online digital resources. By the end, you’ll be equipped with a roadmap to modernize your maintenance processes without breaking the bank 🙂 .

I. First stop on the roadmap: Assessing the Current State:

1. Documentation and Inventory:

Start with the Basics: Begin by documenting all existing equipment and inventory. Create a comprehensive list of assets, including details like age, condition, and maintenance history. What details you want to include in this list? How to code your equipment and update outdated equipment lists?

All this and more is included in SimpleWays Maintenance training: Secrets of Building a maintenance Program. Celebrating 2024, You can get this training at the minimum possible price for only 5 days from the date of this article using this link for the English version: Secrets of Building a Maintenance Program . And this link for the Arabic version: أسرار بناء برنامج ناجح للصيانة . After the welcome 2024 special prices, you can get it with the special discount for our readers using the links in the ads below.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

2. Maintenance Logs and Records:

Review Historical Data: Dive into maintenance logs and records. Analyze past maintenance activities to identify recurring issues, areas of improvement, and patterns that can inform your upgrade strategy. This can be best done using free digital tools to log tasks, issue requests and collect feedback. To know how to build such a system using Google Sheets free spreadsheet app you can join our Google Apps training.

Celebrating 2024, You can get this training at the minimum possible price for only 5 days from the date of this article using this link for the English version: Jump-Start Google Sheets, Forms and Apps Script . And this link for the Arabic version: نطلق بقوة إلي جداول بيانات جوجل والنماذج وبرمجة التطبيقات. After the welcome 2024 special prices, you can get it with the special discount for our readers using the links in the ads below.

LOWEST-PRICE-24F-01M

3. Team Feedback:

Engage Maintenance Teams: Gather feedback from the maintenance teams. They are on the frontline while implementing the roadmap and can provide valuable insights into pain points, inefficiencies, and areas where the system falls short. To create and sustain an Agile maintenance we need to build the maintenance process around motivated maintenance teams and individuals. Why? and How? That’s what we had deeply discussed in this article: A Motivated Team makes Agile Maintenance a Reality – Part 5-1. Agility is the key word for this era. It denotes dynamicity and honors users’ needs. What more you could need in this fast-paced world than being agile using your team feedback?!

II. Next station: Identifying Key Areas for Improvement:

1. Prioritize Critical Systems:

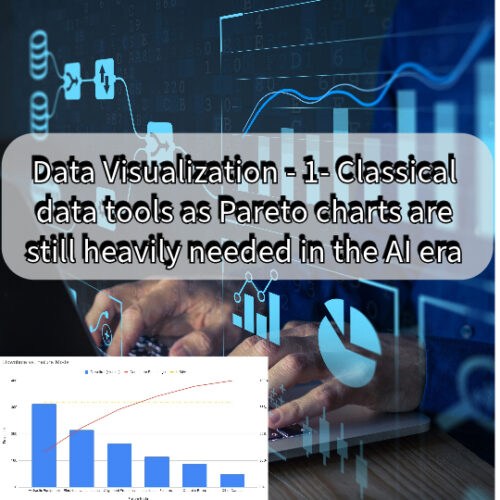

Identify Systems criticality: Prioritize critical systems that impact overall operations and can jeopardize your roadmap. Focusing on key areas ensures that your efforts have the most significant impact on reliability. One of the most relevant tool to our daily maintenance and management work which is the Pareto Chart. It facilitates data-based decisions. You can learn how to apply it from this lecture: Data Visualization – 1- Classical data tools as Pareto charts

Mean while, we can build the complete maintenance process around data analysis and visualization. There is no activity in maintenance that won’t get better by adding data visualization. it’s essential to choose the right types of charts and graphs based on the specific goals and characteristics of the data. All this is briefed in this article: How to build maintenance around Data Visualization? -3

2. Evaluate Maintenance Procedures:

- Review Current Procedures: Assess the efficiency of current maintenance procedures. Identify steps that can be streamlined, automated, or improved for better overall performance. Any maintenance procedure needs a trigger to initiate it. Then it is followed by planning and coordination. In case of emergency we jump to a preplanned task execution and coordination that is available on shelf for emergency conditions aka failures. Lastly, we execute the task and record feedback.

- How efficient is this procedure. How many times we succeed in fulfilling all the steps of the maintenance cycle? Find more in our 5-days special offer WELCOME2024-ME: Secrets of Building a Maintenance Program And this is the link for the Arabic version: أسرار بناء برنامج ناجح للصيانة .

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

- Define Key Metrics: Establish reliability metrics to measure the performance of the existing maintenance procedures. Same measures will denote the success of the upgraded system. Metrics may include mean time between failures (MTBF), mean time to repair (MTTR), and overall equipment effectiveness (OEE). More importantly are the control limits of each metric. What is the correct lower limit that will raise a flag that this equipment needs extra care? And what upper limit will mark the success of the maintenance system?

- Make use of SimpleWays maintenance consultancy and coaching sessions to properly set and tune your maintenance roadmap. You can unlock this opportunity via this link: Store for Maintenance and Digital Services

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

III. Get help with your roadmap: Basic Tools for Upgrade:

Utilize Spreadsheets:

Excel or Google Sheets can be powerful tools for organizing data, creating maintenance schedules, and tracking inventory. Google sheet is available for free with your Gmail account. Develop templates for preventive maintenance checklists and asset management. You can join our Google Apps training.

Celebrating 2024, You can get this training at the minimum possible price for only 5 days from the date of this article using this link for the English version: Jump-Start Google Sheets, Forms and Apps Script . And this link for the Arabic version: نطلق بقوة إلي جداول بيانات جوجل والنماذج وبرمجة التطبيقات. After the welcome 2024 special prices, you can get it with the special discount for our readers using the links in the ads below.

LOWEST-PRICE-24F-01M

Explore Task Management Tools: You can build and customize your own task app as we had done together in the Google Apps training linked above. Otherwise, you can look for the free tiers of apps like Trello, Asana, or Todoist that can help organize and prioritize maintenance tasks. Create boards for ongoing projects, assign tasks to team members, and track progress.

Implement Cloud Storage:

Platforms like Google Drive or Dropbox provide secure cloud storage for maintenance manuals, schematics, and documentation. Moreover, this ensures easy access to crucial information for the entire team anytime anywhere.

Leverage Communication Apps:

Personally I had relied on social media groups for years to communicate to work team. Most or little less of our time outside the workplace is on social media. Free few of us switch OFF all media notifications. Now what is the social media app that most of your team use and create different functional groups and dedicated channels there and add them in case this is allowed :). Otherwise Tools like Slack or Microsoft Teams facilitate real-time communication among team members. You can use their free tiers to establish dedicated channels for maintenance discussions, issue reporting, and collaboration.

Advanced Maintenance roadmap in 2024-2 will come in the next lecture carrying 2 important sections

- Advanced tools from Free & discounted Online Digital Resources

- and, The roadmap Implementation Strategy

In Conclusion,

Upgrading an outdated maintenance system doesn’t always require a substantial financial investment. By leveraging basic tools and free online digital resources, organizations can embark on a journey towards a more efficient and reliable maintenance framework. This will make the roadmap to take maintenance to the next level in 2024 real. The key lies in a systematic approach — from assessing the current state to implementing new tools and continuously refining processes. With this guide, your maintenance system can evolve with the times, ensuring longevity, reliability, and improved operational performance.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment