That’s what our friends from the Uptime book, John Campbell & James Reyes, they name it the “Basic Care”. The absolute minimum level of maintenance is when you apply a bare 100% reactive maintenance program. In other words, when there is a failure, the maintenance team respond to this failure and return the machine back to operate. What do we mean by “bare”? It means that there is no other tasks for the maintenance or production teams that target caring about the machines. Cleaning occurs when we can’t produce, greased when the friction hinders the production and, so on.

However, this situation is very pessimistic and you can rarely found it. Depending on your global location, there are minimum set of regulations that govern the operations of any production facility. That’s a good starting point to express what can the basic care be.

An analogy from life to understand basic care or minimum maintenance

If you need to understand better, think about three friends. One of them had felt some abnormality in his physical body performance. When he visited the doctor, the doctor asked him to urgently start some physical exercises. Beside this he needs a strict diet and a long list of medications. Before that he never thought seriously about his physical body.

The second one regularly walks, runs, goes for hiking and his diet is balanced. He takes fatty food occasionally and healing herbs are intentionally a part of his diet. When he feels a light abnormality in his physical body, he reviews what he unintentionally missed out of his routine. He might add some natural recipes, healing vibrations or meditations. His life is going on without any serious problems from his body.

The third friend is a fitness addict. He is in the gym almost daily. He examines and scans his body thoroughly and run to an action at every symptom. His diet is strictly vegan or keto or whatever. He advocates his performance and has a lot of fans on the social media who asks about how he achieved those results. He never questions how reliable is his regime. But he tends to increase and grow his body fitness as number one priority.

Those life examples represents two extremes of the care given to maintaining our physical assets and a mid point between them. The mid range is so wide that it can accommodate a lot of conscious practices as long as we have clear targets to reach.

Regulatory minimum maintenance tasks.

Regulations might not include the word maintenance in their guidance, punishment or intensive procedures. However those regulations point out to the need of some intended maintenance activities implicitly.

Usually the national regulations urges compliance with certain figures that eliminates any risk to the environment, society and the employees of this production facility due to its production activities. The effect on the environment includes the wastes produced from the production activities. The effect on the society includes the safe use of this product and, the product usefulness. Otherwise, customers might not purchase it. The risk on the employees includes the risk of fatality, injury or health deterioration.

We may place zero targets on all the regulatory elements. But, there is a minimum occurrence that we can’t avoid and the regulations allow it. So, you produce wastes as side products and you produce defected products. Regardless of your controls, some defected products might reach the hands of a customer. Even some injuries might occur in the workplace. That’s why the regulations place some limits on those incidents. However, you need to internally work on tighter limits to stay within a safe margin. Otherwise, business might face punishments by the regulations. Ignoring these regulations might result in business permanent shutdown by the authorities.

You can’t avoid a set of maintenance activities or basic care of the equipment to safe guard your business continuity.

How maintenance affects the regulation compliance?

As we had said, from the point of view of the regulations there is an acceptable amount of wastes produced, emissions and some minor injuries that might occur. The condition of the machines and how it is operated affect to a great extend the wastes, emissions and safety of the personal.

Take any vehicle as an example. The way we drive the car, load it and maintain it affects the economies of its operation, the wastes and emissions and the safety of the driver, passengers and the people in the streets where it commutes.

Like the driver of the car, the machine operators are the first line of maintainers. They notice any abnormality and explain it to the maintenance team. Meanwhile, the maintenance team is busy doing more detailed inspections of well crafted inspection points and preparing the nearby cyclic preventive maintenance. The operators give the time for the periodical maintenance and the repair of the partial failures they had noticed.

If this scenario is not taking place in any facility, then failures will occur. Regardless of the capabilities of the maintenance team to retrieve the machine operation condition at the earliest, some losses occurred due to these failures. The raw material lost is more than those planned for the machine setup. Some out of spec products were produced that need to be scrapped. Liquids leaked and need replenishment. Gases, dust or fumes escaped to the surrounding environment. Any of these wastes might be harmful to the environment, surrounding society or the employees.

So, having a maintenance program in place safeguard the business from being subject to the fines or penalties that result from crossing the borders of the regulatory limits. You can learn how to set a winning maintenance through our Arabic and English trainings below

When minimum maintenance is too much?

It is either one of two scenarios. The first of them is when the regulation are too tight and so detailed that forces the organization to over maintain or inspect the equipment. This case occurs when the regulations are accident driven and with every accident it adds tighter regulations. The other scenario is when the maintenance team over reacts in response to the claims associated with failures by adding extra maintenance jobs. Or, they try to reach the figures of best practices by overworking the maintenance not rationalizing it.

But, what is considered as Basic Care or the minimum needful maintenance?

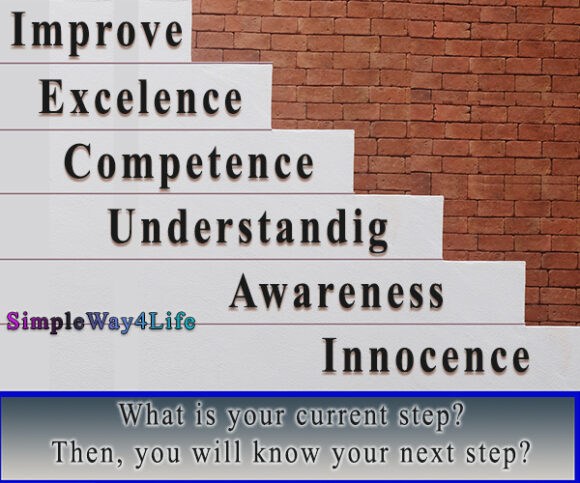

Really it depends on the culture of the organization and experience of the team. Maturity of the Basic care grows from innocence when we are not complying to the regulatory rules and maintenance is reactive in most. Maturity grows up to the professional level where we are 100% compliant to the regulatory rules. And, we have a balanced maintenance program. WE balance the maintenance program through analyzing and rationalizing what we do; i.e. we do only the needful maintenance. At this stage maintenance is effective, it does only the right and needed maintenance activities and, efficient; It always does maintenance activities in the right way from the first time.

Let’s say it in another way. The minimum Basic care of the equipment is the set of activities that we do to barely fulfill the targets. Those targets can be the regulatory limits of how often we inspect the safety sensors of a boiler and record this. Or how often we use a third party calibration for our internal scales. Or, It might be a set of internal requirements as the maintenance cost or downtime or any other KPI that our organization uses to verify the maintenance performance

Is it wise to exceed minimum maintenance?

Achieving better targets and results is always welcomed and counted into our credibility as long as it doesn’t jeopardize other targets. Example, there are no unscheduled maintenance activities, however availability dropped to 80% (>90% is the best practice) due to scheduling too many maintenance tasks.

Some consider that time based preventive maintenance or, operations’ number based preventive maintenance is the minimum basic care. Others consider it a wasteful activity and they consider Condition based maintenance the minimum limit. Some others consider the built in predictive tools as the starting point for having acceptable maintenance. And so on, wherever you reach in the maintenance, you will will raise your own bar.

In conclusion,

You can set the minimum level of maintenance that you would like to maintain any where from total reactive to total preventive. However you need to make sure that your selected minimum level matches the level set by the regulatory body or by the organization in the form of KPIs. Anyhow, after we fulfill this critical minimum maintenance level of basic care in a way that is acceptable by the authority who set it, you can freely upgrade the maintenance performance. Your limit is the sky, however, you need to balance the direct costs, the indirect costs and the maintenance performance indicators.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store