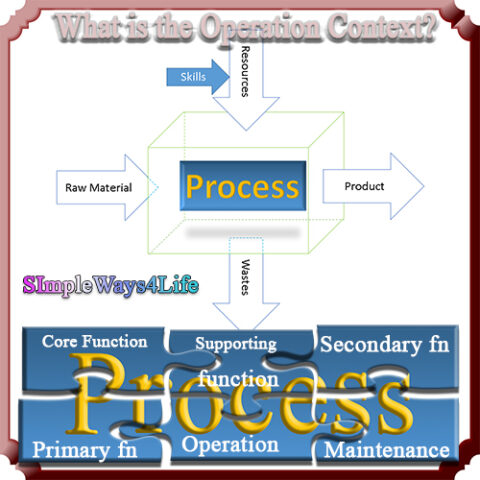

In our previous chat How to transcend old maintenance perceptions? we had explained that maintenance is easy and safe to do when you have enough knowledge about the job and the risks and hazards it includes. These knowledge is found in the maintenance documentation. How to make this knowledge available for the users and the maintenance team so they are confident in the maintenance practices and results, that’s the scope of our chat today.

Whatever we are speaking about here holds true whether you are controlling maintenance through a paper system or a computerized system. The difference is that the document we will be speaking about is either a sheet of paper in your hand or the screen of the mobile/tablet or the computer .

Do we need any documentation for maintenance?

That’s an important question. Many simple maintenance activities are done naturally without the need for documentation. You change the light bulbs at home, you check the coolant and oil of your car. You can find the Tyre repair shop adjusting the air pressure without checking you car name plate or the Tyre recommendations. Guess what? He might adjust it to the incorrect pressure. Why? because it varies based on the car manufacturer recommendations and the usage. If you intend to use it at full load or higher speed you might need different settings. If the car tyre is hot after a long drive, it will give a different reading.

But what happens if the air pressure is not correct? It affects the tyre lifetime or technically wear rate. Additionally, it affects the fuel consumption. And lastly, the vehicle safety. So, if you ignore the air pressure adjustment or adjust it incorrectly you risk being subject to any or all of these problems. Have a look to online references from BRIDGESTONE and a local UK Tyre shop.

But why the air pressure of my car tyres change and I need to check it monthly? Because it is subject to environmental conditions of the road and in some cases harsh usage – do not take it personal -.

Do I need to repeat reading it?

But Guess what? After few months, these figures are stamped in your mind and you don’t need to check the door nameplate every time. Yes but what when your child takes this mission, he needs to be guided to a source of information or ** Documentation ** to return to each time till he is well aware of it.

What if each member of the family adjust the car air pressure differently? None of the car drivers will fell comfortable or steady while driving the car.

OK, that’s not a tutorial about car air pressure but as we are used to we use simple everyday life situations to bring the maintenance concepts closer to our minds. Relating the maintenance practices to simple examples will imprint it in our minds and will give us the the opportunity to spread the information in a more appealing way.

What are the documentation needed for maintenance?

Well, maintenance is an activity that need to be done in a certain way through some specific steps to achieve a result. So, the maintenance document should include these information clearly:

- The steps before, during and after the maintenance activity

- What is the result expected after the maintenance

- How to measure this result – if a measurement is applicable-

What are the source(s) of this information?

Typically these information are found in a document called the Maintenance Manual. This maintenance manual or maintenance instructions are delivered with the equipment. If not, You have all the rights to ask for it.

What if the machine is a second hand one or it had been here for a long time that no one knows where these documents are?

Here you have some options:;

- If the manufacturer is still available and there is not restrictions to communicate with it, go ahead

- Look online for some manuals to download. The online archive is huge

- That’s a website for free old manuals: https://ozarktoolmanuals.com/machinemanuals/

- And that’s a paid one: https://industrialmanuals.com/

- The third option: Record what the team is currently doing and consider it your maintenance manual

- Post your needs on Maintenance Forums as:

- Outsource the maintenance activity

- Invite a consultant or subject matter expert to support you

What is expected to be found in these Maintenance Manuals?

- Identification of the machine. i.e. the model that this maintenance manual is speaking about. At a coming chat we shall be discussing the importance of correct machines coding .

- Precautions that need to be taken before starting such maintenance. Those are the safety instructions that need to be followed including the tagging and locking if applicable.

- Parts type needed if any

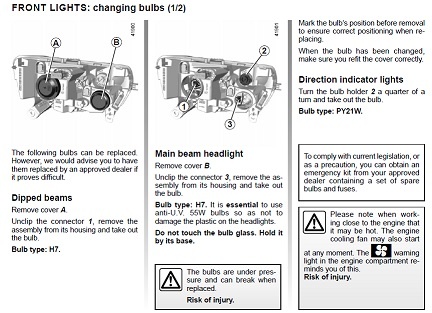

- A visual description of the maintenance positions. This is debatable. Some suppliers believe that skilled technicians know the part by description not image and that is the level of qualification needed for maintenance. We shall give examples from many manufacturers in a coming chat.

Below in Figure 1 is an example of car bulbs change just as a demo - The period to each maintenance item

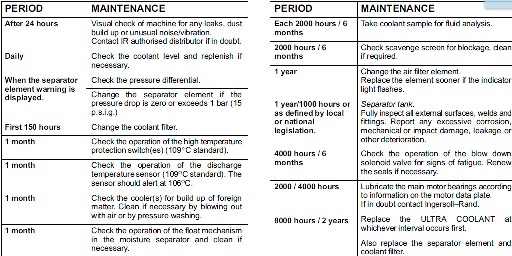

You can see this in Figure 2 below as an example from Air compressor maintenance manual - Some of the maintenance activities are inspection and testing for the condition of the equipment. Those should include a criteria to compare with and a procedure to test.

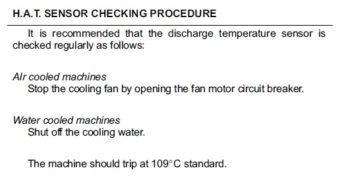

See an Example in Figure 3 below

Last point about Maintenance Manuals, Are they directly usable?

For Personal equipment like your car, your computer etc.. YES

For Industrial equipment, even on a small workshop scale, it is recommended to treat those manuals as valuable assets, well preserved or maintained. Then based on the scale of the business, either the maintenance responsible person or, the planning team use them to generate the maintenance system or maintenance schedule and drive from it the work orders and the activity checklist related to each work order thereafter.

In Conclusion,

Maintenance starts with a document telling you what should be done to maintain the condition of this specific equipment. We had touched today at a high level what is expected to be found in the maintenance manual and how to get use of it. We shall chat again and again around documentation and the secrets to make it work for you.

Enjoy your coffee and stay safe.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

7 Comments