In the last part of the previous chat Why Maintenance is Important?, we had approached the meaning of a partial failure and how to detect it. Partial Failures detection and repair clarify the added value of maintenance. Though this aspect of maintenance activity is vital, it is difficult to quantify it. The only way to quantify its value is through calculating the effect of performance decline on the business. One of the important performance indicators that allows the tracking of such decline is the famous OEE. OEE is the Overall Equipment Effectiveness metric. To understand the OEE we need to refer to the SMRP -Society For Maintenance and Reliability Professionals- definition and its method of calculation.

OEE Definition

MANUFACTURING PROCESS RELIABILITY METRIC

OVERALL EQUIPMENT EFFECTIVENESS (OEE)

This metric is a measure of equipment or asset performance based on actual availability, performance efficiency and quality of product or output when the asset is scheduled to operate.

SMRP Best Practices – OVERALL EQUIPMENT EFFECTIVENESS -OEE

OEE calculation

Overall Equipment Effectiveness (%) =

Availability (%) × Performance Efficiency (%) × Quality Rate (%)

We shall examine the effect of maintenance on each part of the metric. This metric genuinely gives a measurement for the process reliability. We need first to understand what is Reliability:

Reliability:

The quality of being trustworthy or of performing consistently well.

Definitions from Oxford Languages

The OEE – Overall Equipment Efficiency – is a key indicator of the process reliability as it gives a trend of how reliable your process is?

From the business point of view, you need a reliable production process to build your calculations for the investment and marketing. If you are not sure whether tomorrow your machines will be producing or not?. Whether it will produce enough products?. And, will it be of an accepted quality to the customer?. Then, you can’t plan your business, market it or commit delivery to consumers. In other words, this is not a business or at least not a profitable business. Let us start by the less obvious parts as Quality Rate and Performance Efficiency.

Effect of Maintenance on the Quality Rate

The Quality Rate as well as the Performance efficiency and Availability need to be as close as possible to one (1) or unity to make the resultant OEE nearly Equal to Unity (1)

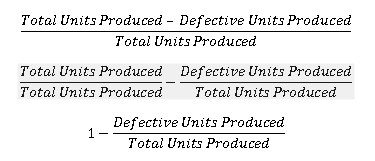

Quality Rate =

So, for the Quality Ratio to be unity, The defective Units produced needs to be zero (0). Surely Maintenance is not the only contributor to product defects. Product defects can come from the raw material used and operation practices. But any how on our way to pursue zero defects we need to understand the cost of quality:

- Scrapping defected products (Internal Quality Failure)

- Recall and compensation of delivered defected products (External Quality Failure)

- Quality Inspection cost

- Defects Prevention Cost

As we had explained in an earlier chat To understand Maintenance, Start from Business, business targets generating profit. Decreasing costs and maintaining reputation are key elements in generating profit.

Examples of Product Defects due to Maintenance

First thing, maintenance tasks are not executed only by the maintenance team. Many organizations assign maintenance activities and maintenance inspections to the operation team. This can be due to the small size of the organization or, due to applying TPM. TPM is the Total Productive Maintenance. Or applying some of its initiatives. One of TPM main ideas is “Getting operators involved in maintaining their own equipment”.

Examples:

- The dosing or weighing system

- It is applicable when some chemical additives or food flavors are added to the mix

- Calibration of the dosing unit or the weighing system is a maintenance activity regardless it is done by the maintenance, operations or even quality team

- Incorrect calibration or wrong calibration cycle will result in a product out of spec.

- This product is either scrapped or will be down graded

- Both options include financial loses

- The cutting system

- The cutting mechanism has many components

- Cutting blades, need to be sharp, well fixed and gaps calibrated

- Blades carrying and moving mechanism, Needs lubrication, fixation and cycle calibration

- Any incorrect or overlooked maintenance action in any of these components will result in wrong cutting

- Results of wrong cutting varies based on the industry

- In paper industry, you will get edge ridged or turned down; and inaccuracies in cutting, like overcuts and undercuts

- In steel industries specially with big volume production that implies high speed operation. The steel stock in the line running at high speed will be scrapped at wrong or failed cutting.

- The cutting mechanism has many components

- We had discussed that it is safer to operate a well maintained machine for the operator and the equipment in a previous chat. But, you can give yourself a minute to imagine a 2 tons steel bar running at 30m/sec i.e. 108km/hr. Regardless of the result of scrapping those 2 tons of steel and it is considered as defected product, the impact momentum of this 2 tons bullet if it went out of track is unsafe for operators and equipment.

Maintenance Effect on the Performance Efficiency

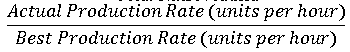

Performance Efficiency =

That is where the production decreases the working speed of the equipment i.e. its productivity decreases due to partial failures.

Examples:

- We shall start with a life example. Suppose that a bus vibrates when runs at a speed of 100km/hr which is the highway speed. Its driver finds a comfortable speed at 85km/hr. thats 15% reduction in its speed. Consequently it is 15% increase in the time of every trip. As a result the number of trips it can make along the day is decreased.

- Same example applies to production lines. If the full speed started to cause vibration for the equipment that leads to screws loosening. Or, due to friction, there is excessive heat that trips the equipment. Then operators will reduce the operation speed and consequently the productivity.

- There are other examples of cooling pumps not delivering enough cooling water for the equipment or heating furnaces shells. Operators will decrease working temperature that will elongate the process or make it impossible.

The opposite scenario: What if the equipment where maintained through maintenance to optimal working conditions?

- Quality defects due to maintenance would drop to zero. Although Quality Rate wont reach unity as the production defects are not solely attributed to maintenance but it would improve.

- Performance efficiency would increase due to two reasons

- Operators will run the equipment at the needed speed

- Operators will have trust in operating the equipment without the fears of sudden failures.

- Sudden failures wreck the safety feeling of the operators in three ways:

- Sudden failures may cause accidents

- The effort needed to clear the messed production and reset the line for operations

- Usually job floor staff do not like the lengthy investigations related to failure

Maintenance effect onAvailability

Availability is the time available for production after deducting scheduled non production time.

However, unplanned stoppage reduces the time available for production and directly productivity.

In Conclusion,

Though here we chatted around the above items together with our cups of coffee, we shouldn’t forget the necessity of having the production and maintenance data recorded and available. Data gives a validation for the action taken and helps plotting it on the progress curve to know if we were on the right direction.

We had discussed practical industrial examples the clarified how maintenance of partial failures or their prevention saves a lot of cost. It saves the cost of degradation of the Quality Rate and Performance Efficiency.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

3 Comments