We need to start with a propping question: Why we need to monitor and control? The origin of this question stems from the target of establishing a business; which is to make profit. Profit here doesn’t necessary means a monetary return. Nowadays, adding value can be reported in other forms as fulfilling social responsibility or contributing to sustaining the earth resources. However you can trace back any of these targets to an indirect monetary value to the organization. So the origin of Why we need to monitor and control? Stems from Why we need to spend on monitoring and controlling? Through this article we shall summarize this answer for the maintenance process from the perspectives of project management.

But, there is an equally important question, what we need to monitor and control? Both these questions of what? and Why? are working hand in hand. If we know the value added from monitoring and controlling the maintenance process we can select what we shall monitor and control to validate the value added. And, on the other hand, if we picked the important parameters that we need to keep track of in the maintenance process, we can deduce the value added from them. Or, at least we can understand the lost value from failing to comply with those targets. When you see the negative side, you can reverse it to reach the positive target you are aiming for. You can equally apply this on business and on life.

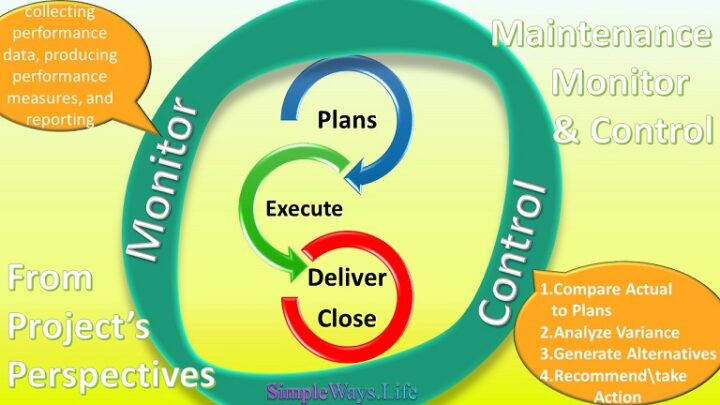

What is monitoring and controlling in project management?

The Monitoring and Controlling Process Group consists of those processes required to track, review, and regulate the progress and performance of the project; identify any areas in which changes to the plan are required; and initiate the corresponding changes.

The key benefit of the Monitoring and Controlling Process Group is that project performance is to observe and measure regularly and consistently to identify variances from the project management plan.

PMBOK 4th Edition

When issuing the Sixth Edition of the PMBOK, PMI (Project Management institute) had elaborated on this definition so you an understand what to do for Monitoring and controlling. So, the Definition of the Monitoring and Controlling process group and its benefits remained the same. But, they added the individual definitions of the monitoring and controlling as below:

The Monitoring and Controlling Process Group consists of those processes required to track, review, and regulate the progress and performance of the project; identify any areas in which changes to the plan are required; and initiate the corresponding changes.

Monitoring is collecting project performance data, producing performance measures, and reporting and disseminating performance information.

Controlling is comparing actual performance with planned performance, analyzing variances, assessing trends to effect process improvements, evaluating possible alternatives, and recommending appropriate corrective action as needed.

The key benefit of the Monitoring and Controlling Process Group is to measure the project performance and to analyze it at regular intervals, appropriate events, or when exception conditions occur in order to identify and correct variances from the project management plan.

PMBOK 6th Edition

Now, The answer to the first Question: Why we need to monitor and control the maintenance process?

The key benefit of the Monitoring and Controlling is to measure the maintenance performance and to analyze it. Measurement and analysis are executed at regular intervals, appropriate events, or when exception conditions occur. That’s in order to identify and correct variances from the maintenance management plan.

This process is divided into two phases the first one is Monitoring which is collecting Maintenance performance data, producing performance measures, and reporting and disseminating performance information.

Firstly, Monitoring first step: measure the performance & collect this data

Maintenance is performing maintenance activities. Measuring the maintenance performance is recording some parameters related to the maintenance planning and execution. Examples of these parameters are the time of executing the maintenance, the time of recovering production after a failure, the number of tasks under planning or in the backlog and the cost of all the parts, manhours and subcontractors used. Then, we should record them appropriately i.e. in a way that we can easily and clearly retrieve and use them digitally. That’s a great benefit of the online digital tools as Google sheets and the cloud computing.

Secondly, Monitoring second step: Produce performance measures

Performance measuring is comparing the recorded figures to the target figures. Universally, this analysis is through generating KPIs or Key Performance Indicators. KPIs imply some sort of calculations using the figures recorded in step 1. From the famous KPIs:

- MTTR, Mean Time To Repair

- OEE, Overall Operation Efficiency

- MTBF, Mean Time Between Failures

- Reactive maintenance percentage

- Planned activities percentage

Moreover, You can learn how to create those KPIs and even your own specific KPIs in our Secrets of Building a Maintenance Program training in Arabic and English

Thirdly, Monitoring third step: reporting and disseminating performance information

Usually we generate Dashboards with green and red regions to visually give a quick clear indication. This way we identify the variance from the plans. Those variances in case they are negative will have negative effects on the production of the physical or soft product of the organization. Then, we need to correct those negative variances in the control process.

Those measures are a crucial part of our weekly, monthly, and surely annual performance reports. Disseminating these indicators or performance results places the whole team and all other stakeholders on the same page. This will stimulate correction proposals and will prepare the team in case a change is need as part of the correction.

The other phase of Monitoring and controlling, Control the performance measures

Controlling is comparing actual performance with planned performance, analyzing variances, assessing trends to effect process improvements, evaluating possible alternatives, and recommending / taking appropriate corrective action as needed.

So, the first step is to have integrated maintenance plans. We explained the components of the maintenance management plan in a previous article; Project planning processes that can help maintenance planning. In the beginning, The maintenance management plan should start with the collecting the maintenance activities and decomposing it into the minimum manageable chunks. We had covered this in our Maintenance Training on Udemy. You can reach it through this link: Secrets of Building a Maintenance Program

Also, The Maintenance Management Integrated Plan includes

- the communication plan,

- risk management i.e. what to do if something went wrong and in emergencies,

- the maintenance quality control i.e. how to perform monitoring and control

- and the cost management plan

Then, take control steps

The control steps that we need to take are:

- Firstly, assessing trends to effect process improvements,

- We had recorded the field data, convert it to KPIs or any comparing technique

- The comparison is between what you had planned for the time, the cost, the quality, the effective communication or the risk responses and what you had recorded.

- Examples:

- Tasks executed according to the plan mainly from time point of view are less than 50% of the planned tasks

- Rework exceeds 20%, Do we follow the quality plan?

- The emergency response in case of sudden failure took extended time or some resources were missing for 40% of cases

- Reactive activities are more than 60% of all maintenance activities

- Secondly, evaluating possible alternatives

- What else can be done?

- Why we take extended time?

- Can we improve preventive or predictive maintenance to reduce Reactive work?

- Did we do a reliability assessment to see if it is feasible to find predictive or preventive tasks for the reactive ones?

- Did we find some missing skills that cause rework? How can we gain these skills? Training? Hiring? Subcontracting?

- Lastly, recommending / taking appropriate corrective action as needed.

- Now you had pointed out the pains

- Through brain storming, consulting or searching online you had came out with probable solutions

- It is time to pick the most relative applicable solution and to put it in action

- Then, you keep monitoring and controlling forever Why?

Then, Why we need to control the maintenance process?

Very simple, things running without control probably won’t achieve the targets originally planned for them. Why? Because Business environmental condition which include ourselves, our team, the software or hardware status, the customers aptitude and many other factors change. Those changes drift the natural flow we programmed from before so we shall end landing on a different shore. In order not to consider the maintenance process as a failing project we either need to change the route or the destination. Catching the drift and correcting the route is done through the Monitoring and controlling. At the end of the day achieving the maintenance targets is a corner stone in achieving the organization goals and profit which is the ultimate target. Why not and we are responsible for maintaining the organization’s assets productive as required. More on What we need to Monitor and control in a coming chat.

In conclusion,

This article had presented a framework for monitoring and controlling the maintenance process from the project management perspective. Seeing things from a different perspective widens our possibilities to streamline our maintenance career.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store