To be able to take any activity to the next level, the next level must be built on the robust foundation of excelling the basics of this activity. But, What are the foundations of Remote Management?

While everything is advancing digitally, industrial management at all levels seeks not to be of a lesser initiative. Due to the nature of industry and the growing of corporate structures that run the production facilities, many activities and decisions are running far from the shop floor. Long ago, this implied the existence of management styles that supports this organizational structure. Now the management levels that need to work remotely is down to the department managers and this idea is no more the monopoly of board members.

I would like to start by an example. Few Years ago, one of the leading heavy industries manufacturer presented how they developed the use of augmented reality. They were having 3 main challenges that forced them to adopt this methodology:

- The scarcity of skilled field installation and commissioning team members

- Having concurrent projects that need the same subject matter expert but in 2 geographically separated distant areas.

- To handle projects in conflict or unsafe areas

Though, I don’t have a medical background but I had read about surgeries that were supervised by senior doctors thousands of kilometres away.

To be able to build upon these examples, we need to realize some common outlines between them:

- There are some data collected from one location and seamlessly transferred to another location

- There is a field team with a relevant experience

- A central remote management

- A medium through which they communicate and collaborate

If what is described above convinced you, wait a moment, there is a missing ingredient.

None of those examples spoke about The Foundation.

To be able to take any activity to the next level, the next level must be built on the robust foundation of excelling the basics of this activity.

If we analyze the example of the remote installation supervisor, The local team need to have the following basics to allow remote management:

- Technical hands on experience in installation

- Tools needed for installation including hand tools, mobile equipment, measuring tools, lifting equipment, etc.

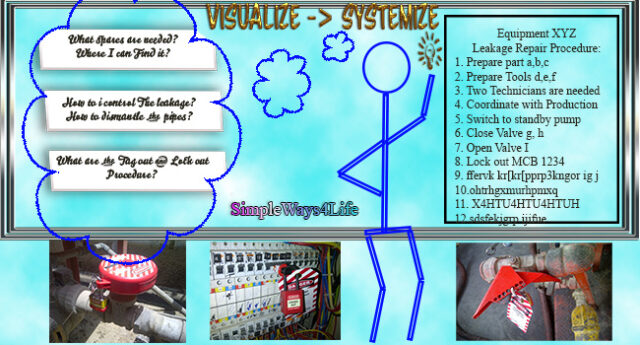

- Common Documentation and naming convenience. So when, we speak the tenth gear box or column 5 , it is well defined and easily recognized by both sides

- Parts available at hand, well arranged and ready to be picked

- Scheduled activities, what we are going to do tomorrow and next hour and what parts, tools and skills are needed for this activity

- Shared records for the results of the activities done

Where this example fits in the maintenance realm?

The collaboration bases mentioned above are not only valid between a local team and a remote supervisor, they are equally needed between our local teams. But first Let us continue the example of a local team and a remote supervisor or a service provider. It is a typical example in any small business and, for some assets in large firms. If this asset involves technological equipment, that ranges from a commercial laundry machine to a CNC (Computer Numerical Control) machine. Errors occurs and settings need to be adjusted. Either there is an in-house expert but that would be an expensive asset. Or the machine remains ideal till the technician delegated by the machine manufacturer arrives. The escape from this trap comes through the local team who has some basic skills, records and documentation that enables them to respond to the directions from a remote service provider. Depending on the level of the technology, some machines are even equipped with remote diagnostic kits as the case of most modern CNC machines. It can be accessed remotely, diagnosed, needed parts shipped and the local team can install the new parts.

What about internal maintenance process, does it need the same foundations?

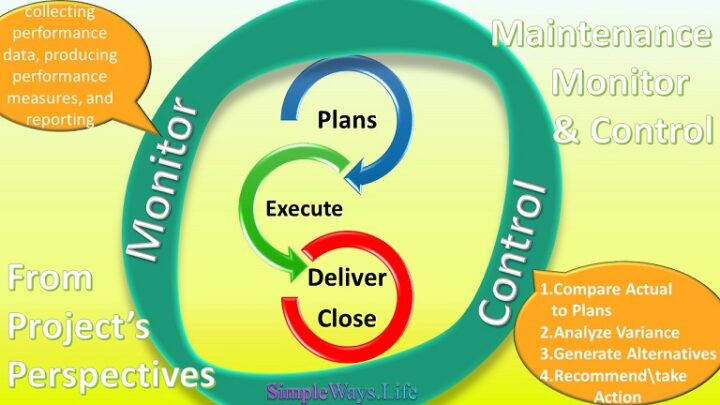

Sure. The maintenance teams, in case they are divided to central and plant teams, the production teams, the planners and all level of management need to exchange a lot of information. These information need to be correctly referenced i.e. there is no ambiguity about the machine or production line we are sharing information about. It s clearly designated in a way understandable by every one. Production and maintenance schedules are clear to every one. Needed skills, tools, parts, support teams and support equipment are clear to every team. Procedure of any job is well documented and feedback is timely collected and analysed.

To achieve this result of clarity in activities and information there should be strong foundations. This clarity facilitate the correct decision making and saves a lot of wasted time and resource.

Do we need a digital system to run this foundation?

The first answer is Yes. But, it depends. For small scale business and few assets, excel sheets can do miracles once you know what you are doing. I mean, you know what to record, what to calculate and what indications are derived from these data.

When the scale of business increases, number of facilities and assets grow, consequently needful activities and physical parts and tools also increase. Manually tracking and analyzing huge number of collected data would require a lot of manpower and adds human mistakes that can surpass the cost of any system

What’s funny about the digital systems is that hundreds of companies now are offering digital management systems for a very small cost. Even if you are running a small local workshop, you can get yourself a management system.

There is a big loud note here. Regardless of how much you invest in the management system or the system brand, without robust foundation of understanding the equipment and the operation and maintenance processes, results won’t be up to the expectations.

We shall delve deeper in coming chats

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store

One Comment