We all reach a moment when the world changes shape. It happens quietly. It comes after years of opening panels, tracing faults, and studying how things truly work. At some point, you stop seeing surfaces. You start seeing structures. You start noticing the hidden logic behind everyday objects. Moreover, You feel the shift in your thinking, and it never leaves you. This is the maintenance perspective, and it becomes a permanent lens.

Maintenance work trains your eyes. It builds your curiosity. It pushes you to question what others accept. Moreover, it teaches you that every system tells a story. Some stories hide. Others reveal themselves only when you look beyond the shiny cover. After enough experience, you learn to read those stories fast. You sense weak points. You sense shortcuts. Then, You sense the small decisions that shape the bigger outcome.

This habit moves with you. It follows you from the workshop into life. You start checking how things are built before you trust them. You ask the extra question before you commit. Consequently, You look at products, opportunities, and ideas with a deeper instinct. The maintenance perspective refuses shallow explanations. It prefers clarity. It wants the mechanism, the reason, the root cause.

As a result, you begin to see more than most people expect you to see. You cannot turn it off. You cannot go back to simple observations. That’s to say: You cannot un-see the connections you now notice. This ability becomes a strength, and sometimes a weight. Yet it always guides you toward better choices. And it continues to shape how you move through the world.

When you start to see, you cannot un-see again. And that changes everything.

The Maintenance Perspective and the Habit of Knowing How Things Work

Many people develop the maintenance perspective long before they join any organization. They open devices, follow wiring paths, or explore mechanisms without being asked. This early curiosity builds a natural understanding of how things operate. As a result, they adapt to maintenance work with ease. Patterns make sense to them. Faults feel like puzzles rather than problems.

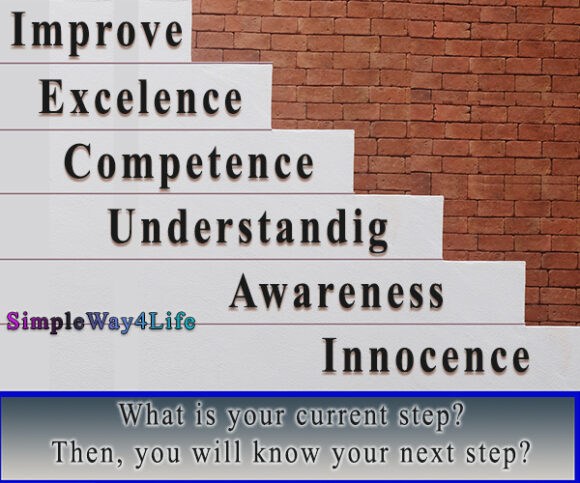

Newcomers who carry this instinct usually progress quickly. Others grow through strong will and training efforts into it after exposure to real equipment and real issues. Both groups succeed when they commit to the extra effort. They learn each component’s purpose. They study how forces move through a system. Like this they see for relationships between symptoms and true causes. Because of this mindset, their competence increases steadily.

However, some workers resist the depth maintenance requires. A few prefer action over understanding. Quick answers appeal to them more than careful inspections. This approach works for simple tasks but collapses under real pressure. Maintenance does not support shallow attention. It exposes gaps. It punishes assumptions. Consequently, people who avoid deeper learning repeat the same mistakes. They overlook clues that experienced eyes catch instantly.

In practice, the difference becomes visible. Individuals who embrace the maintenance perspective build confidence and speed. They no longer guess their way through a fault. Analysis guides their steps. Curiosity guides their learning. Meanwhile, those who resist the weight of this perspective remain stuck in a cycle of uncertainty. The job keeps demanding insight, yet they keep avoiding it.

Over time, the contrast widens. The ones who dig understand how equipment behaves. They can explain failures. They recommend improvements. The ones who stop at the surface struggle to keep up. Maintenance rewards those who want to know how things work, not those who hope the answer appears on its own.

Clarity grows from effort. And effort grows from curiosity. Knowing how things work is not a skill you add later. It is the foundation. Everything else grows from it.

2. Curiosity as a Practical Survival Tool

Curiosity keeps maintenance work safe, reliable, and predictable. It is not a luxury. It is a requirement. Every task demands attention beyond the surface, and every mistake hides inside details someone ignored. Because of this reality, the people who thrive usually ask one more question than others. They want to understand why a fault happened, not just where it appeared. This habit protects equipment. It also protects them.

Many practitioners enter the field with a natural drive to explore. They lift covers, examine labels, and search for the logic behind each step. Others develop this behavior after seeing how easily small assumptions create big failures. Either way, curiosity becomes the force that guides decisions. It shapes how they inspect, troubleshoot, and verify tasks. Over time, it becomes the backbone of a strong maintenance perspective.

Some workers treat curiosity as extra work. They prefer speed over understanding. They want quick fixes and simple answers. This approach feels efficient in the moment. However, it fails when equipment behaves unpredictably. Machines rarely respond well to shortcuts. Without real insight, technicians repeat faulty steps, miss hidden risks, and struggle to solve unusual problems. Maintenance exposes those gaps quickly.

Experienced practitioners know that curiosity lowers risk. They slow down at the right moments. They check clearances, confirm alignments, and review small details others skip. As a result, they deliver consistent outcomes. Their decisions feel steady because they build them on understanding, not assumptions. This behavior often looks like talent, yet it grows from practice and patience.

A strong maintenance perspective trains people to look beneath symptoms. Curiosity makes that possible. It reveals root causes, hidden weaknesses, and early warnings. More importantly, it helps practitioners stay ahead of failures. When curiosity becomes routine, reliability becomes predictable.

Curiosity is not optional in maintenance. It is survival.

Life After the Threshold: You Can’t Un-See What You Now Understand

There is a point in every practitioner’s journey when the view changes permanently. The shift rarely arrives loudly. It grows through repeated observations and repeated confirmations. Once someone understands how a system works, they begin to notice patterns everywhere. They see early warnings. They sense hidden causes. That’s why they detect shortcuts before they collapse. After this moment, the old way of looking at things disappears for good.

This threshold forms naturally through experience. People who cross it start recognizing the mechanics behind everyday situations. A loose detail in a conversation feels like a loose bolt in a machine. A promise with weak structure resembles a misaligned coupling. A product that looks good but feels wrong triggers the same suspicion as a noisy bearing. These comparisons appear without effort. They come from a developing maintenance perspective.

Some practitioners enjoy this expanded awareness. It prepares them for better decisions. It saves them from poor purchases, weak tools, and unreliable commitments. The world becomes clearer, and clarity feels comfortable. However, this awareness also creates weight. It becomes impossible to ignore flaws once you notice them. It becomes difficult to trust simple answers. As a result, many practitioners see more complexity than others expect.

In practice, this new vision guides behavior inside and outside the workshop. It helps people anticipate failures, prevent surprises, and question promises that sound too easy. The habit of digging deeper becomes automatic. It leads to smarter evaluations and safer choices. It also strengthens judgment, because understanding reduces doubt.

Life changes when you start seeing underlying systems. A strong maintenance perspective transforms casual observation into structured understanding. You stop relying on luck. You rely on insight. And that shift stays with you.

You cannot unsee what you now understand. You carry it forward, everywhere

In Summary,

The maintenance mindset builds an unusual kind of clarity. It pushes people to look under the surface, trace causes, and understand how things truly work. This perspective improves decisions, strengthens confidence, and exposes shortcuts that others miss. However, it also creates a responsibility to keep looking deeper, even when the answer hides behind effort.

There is more to explore. This shift in how you see the world affects how you judge quality, evaluate tools, and navigate claims in a noisy marketplace. The next article continues this line of thought and expands the view. Stay ready for part two.