In our previous chat we had started an approach to maintenance system MS-APR by explaining the importance of information flow. It is like the blood flowing in the body. We had demonstrated using examples how the information flows and how each part of the information network and feedback gets the benefits of this information flow. You can read more about it in this link: Can the Maintenance live without its Blood? A Maintenance System Approach MS-APR-1. Today we need to have chat around our loved cups of coffee about the availability of information. Is the Information REALLY not available?

Why we collect the information?

What do you need to take a decision or to know whether you are on the right track or the wrong one? You need some information to analyze.

Even if NOW you have no information history in hand, start NOW to record the data you receive in an easy way for you to retrieve. We are speaking here for all size of businesses. So, don’t wait for a magical computerized system that will make you the analysis. If the manual system failed, the computerized won’t succeed. The manual system here do not necessarily mean maintenance cards for each machine. Nowadays you will find some computers or tabs in the workplace where you can run simple excel or similar spreadsheets programs.

The target from having any sort of data recording is to create some history that you can analyze. So in case that you don’t find information about how a certain piece of equipment was performing the last year or month, it means that you failed to generate a sustainable recording medium for this information.

A Quick brainstorming about what information is needed:

What you want to know? Will show you what data to record. As a starting point to dig for data we start from an easy approach then we shall delve deeper into the prevention and prediction.

When an equipment stops, the main target is to put back to operation:

- What is the problem? Do you have an alarm list?

- Do you know what was the action taken when this alarm came before?

- Did we change some parts? a sensor for example

- Is there a spare sensor in the store? How can I find it?

- How to isolate the machine to make it safe to change the sensor?

- Is there a schematic for the sensor connection?

- When was the last time this sensor failed?

- Is it repeatedly failing? Does it have an affect on production?

- How much time we need to repair it?

- Why the sensor fails? Was there any action taken to protect it?

If the sensor example didn’t resonate with you, let we repeat it with a leaking seal:

- What is the problem? How it was detected?

- A sound? A liquid or air leak? Was the pressure not building? Did an Alarm came? Do you have an alarm list?

- Does it have an affect on production Now? Or, will it affect the production after some time?

- What happened the last time we faced same problem?

- Did we change some parts? a seal for example

- Is there a spare seal in the store? Or, You can use an equivalent one? How can you find it?

- How to isolate the machine to make it safe to change the seal?

- Is there a drawing for dismantling? What parts need to be removed? What tools are needed?

- Is it linked to an electric actuator? How to remove it?

- How much time we need to repair it?

- When was the last time this seal failed?

- Is it repeatedly failing?

- Was the seal properly stored? Is it of the correct type? Was it correctly installed?

How those previous questions will help to improve the maintenance system?

Most of those questions are vital to return the equipment back to operation or to normal operation in case it was a partial failure. One or two questions speaks about analyzing the collected data if any.

The answers of the questions that target returning the equipment back to operation will make your life easier at the next failure. You had already recorded the answers to the questions needed to repair the failure. So it is all a matter of execution at the next failure PLUS recording the feedback of the new failure to make sure that nothing new happened.

The analysis questions will draw a trend for the performance. Either you build on the trend so you can each a conclusion or you disrupt the trend.

Suppose that this is the first time this failure occurs and the equipment is fairly new.

You have some scenarios of how the response will look like:

- You will return to the maintenance manual to know what to do.

- Experienced Technicians will propose some recommended actions.

- Supplier may be contacted for advice

- Then, you look for answers of some questions like how to lock and isolate the equipment, what parts, tools and skills are needed, how much time it will take and how to know that the right job is done. Refer to our previous chat Maintenance 101 : Documentation – 1

- As we explained, you will find answers in the manual, at the supplier or from the expert members of your team.

- If it is the first time to do the job and you need some parts that are not available, the repair start is delayed. Either the equipment will remain idle till repair or will operate with precautions at a compromised level of operation.

- Then, few minutes, hours or days the equipment is back to operation normally. Either you were praised or claimed but, as usual everything comes to an end. It is your choice what will happen on the coming failure as it unavoidably will come.

Answer these questions in advance

You might have the bliss of being well organized and well trained. Then, all the documents we had spoken about as the locking and tagging for different equipment, schematics and assembly drawings, spare parts lists and tools lists are available and their location is known. That’s great even rare. So pat yourself on the back.

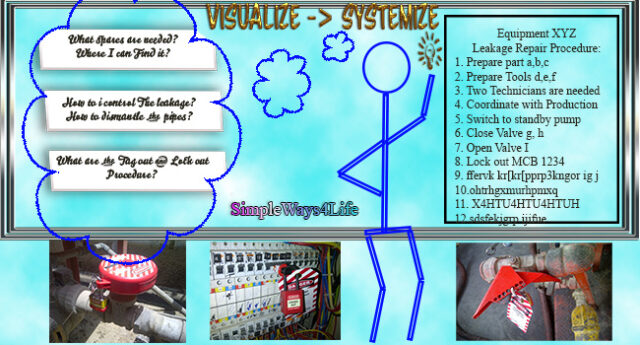

However, from experience, give yourself and your team some daily tasks of visualizing some of those failures and responding to them. See the details of who is doing what? And, the disassembly and reassembly processes and the parts needed. This will help you to close the gaps between what is initially written and what the real scenario can look like. Sometimes everything is in place, but there is no overhead or jib crane to support the operations. If you visualized you need one and it is not there, look for alternatives or take action to install one.

The previous questions will help you do the visualization process.

How to record the feedback after job is completed?

Lengthy paragraphs in the shift log book will be confusing more than helping if not answered the above questions, in a readable, searchable form and in turn. The order of those questions is yours to do. But, make sure that it is every time the same order so anyone can grasp the information quickly.

After the structured data recording, leave the reporter a space to write in his words any additional information, realizations and recommendations. You will find gems in those writings beside their effect of allowing the reporter to express freely. Some of these data -if repeated- can be added to the structure of the feedback report or checklist. One of the vital questions that is overlooked: Can we prevent this failure?

Next Time Same Equipment fails

That’s where you really will feel the value of the recorded information. Again and Again, the problem is not in the recording. The problem is in recording the details somewhere where everyone can reach and understand. It shouldn’t be exactly the same failure. Maybe another actuator or sensor failed this time but now you have a some basic information available:

- Where are the documents

- Effect on Production

- Tag out and Lock out

- What spares are available?

- Any pre-disassembly or cleaning is needed for the equipment

Don’t panic if the same failure is repeated. Now, you have the opportunity to do some analysis and discuss what went wrong. Some key KPIs as MTBF -Mean Time Between Failures- and MTTR -Mean Time to repair- can start to show some results. In case that’s the nth time the equipment fails and whether the production is compromised or not let we move to the next section.

Repeated Failure and the power of information

Here we shall discuss from the point of view of information availability. At any point of time you have the option to decide to start to record a structured feedback of the maintenance activities whether it is a repair activity or a periodical maintenance.

In case that the failure is repeated and you feel that the condition is blurry. The condition is blurry when you are not sure if you have a spare part or not or how much time this problem will take. Also, it is blurry when you were not anticipating a coming problem and trying to solve it. This means that there is a problem of the feedback and activities recording. This problem can be one of three:

- No data is recorded. The experienced team at field is taking action without recording. Everyone suffers when they are not available. That’s when you need to know that you have no working system in place. This conclusion is regardless from the fact that maybe you have the most expensive system in operation.

- Not enough data is recorded. It is only a matter of checklists that the reporter tick them carelessly. The comments field is always empty.

- Data is not analyzed. Feedback is entered to the system whether it is a manual system or a computerized one. The target in position is linked to a false target of performing the scheduled maintenance and recording a feedback. There is no target placed for improving the performance.

In Conclusion,

If you have information you will know how and where to spend your time and money. The maintainers will have confident in maintenance practices and results.

If you don’t have enough data start small but where mostly needed i.e. where you have most of the pain. And, where you can roll out a success story.

You can start from how do you group your assets. by location or technology or production lines?

Enjoy your coffee however you like it, it is a bless.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store