In maintenance, clarity is power. But there’s a fine line between sharp and aggressive. Sharp instructions guide without cutting into focus, trust, or morale. In Part 1, we explored how too much detail can overwhelm. Now, we go deeper—into the language of instructions, the level of abstraction, and how to shape communication that fits the task, the team, and the moment.

Not every detail belongs in every task. A technician installing a motor doesn’t need alignment specs if that’s a vibration specialist’s job. That step becomes one clean line: “Hand over for alignment and verification.” Smart abstraction avoids clutter, respects roles, and keeps teams on track. In this part, we learn how to set that language—clear, lean, and field-ready.

from 24 FEb to 01Mar:

First: Choosing the Right Instructions Level – How Sharp Is Too Sharp?

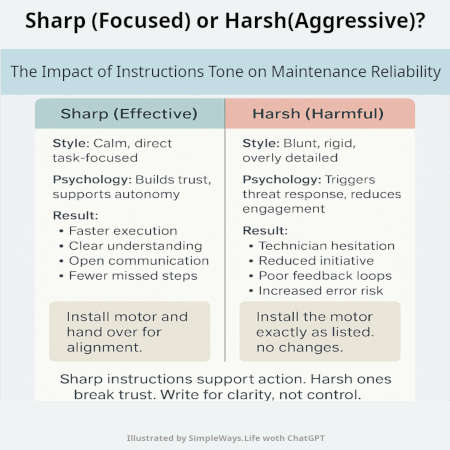

Sharp instructions drive Reliable Maintenance. But there’s a difference between sharp and harsh. Precision builds clarity. Harshness breaks trust.

✂️ Precision Without Pressure

Clear language speeds up tasks. But when words feel like commands instead of guidance, technicians withdraw. Even a correct instruction can sound like blame if the tone cuts too hard. That’s not sharp—it’s threatening.

Psychology calls this the threat response. When people feel attacked, their brain shifts to protection, not execution. They miss key steps. They avoid feedback. That’s dangerous in maintenance.

Technically, over-sharp instructions can bypass problem-solving. They remove judgment from skilled hands. That lowers engagement and raises long-term risk. Good instructions inform and guide—they don’t dominate.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

📚 Backed by Psychology and Standards

The SCARF model (David Rock, 2008) explains why this happens. Instructions that reduce autonomy or status create resistance. The brain reacts as if it’s under threat. In maintenance, that shows up as shortcuts, silence, or missed steps. SCARF refers to Status, Certainty, Autonomy, Relatedness and, Fairness.

From a standards view, ISO 55001 emphasizes role clarity and respectful communication. Reliability-centered Maintenance (RCM) also encourages team awareness, not command-and-control behavior.

Sharp instructions must respect the human behind the task. They should focus, not frighten. Set boundaries, not blame. Guide the work, not control the worker.

Reliable Maintenance comes from clean, respectful communication. That means writing instructions with the technician in mind—clear, confident, and calm.

🔎 Sharp = focus in this context but with a pinch of abstraction

Not all tasks need the same level of instruction. Sharp instructions work best when they match the task’s complexity, risk, and the technician’s role. A mismatch leads to confusion—or worse, mistakes.

Some tasks need step-by-step directions. Others just need a handoff note. The key is to adjust detail, not just add more. That’s how we keep instructions sharp, not dull or overwhelming.

When instructions cover what’s outside a technician’s scope, they slow things down. Worse, they cause hesitation. For example, when installing a motor, “Install motor and hand over for alignment” is enough. Alignment, balancing, and vibration analysis belong in separate instructions. Each team needs clarity, not crowding.

Second: Blending Abstraction with Sharp Instructions

Sharp instructions aren’t just about saying less—they’re about saying the right thing, to the right person, at the right moment. That requires strategic abstraction. In this section, we explore how to blend abstraction with clarity without losing control.

Ready to transform your mindset? Click and Get your copy > Now For Sale on Simpleways.life & Amazon

📍Write with Context, Not Just Accuracy

Not all instructions make sense out of context. Saying “Tighten to spec” assumes the spec is known. For field teams, it’s safer to say, “Tighten to 120Nm using torque wrench.” or “Tighten using a torque wrench. Refer to Bolts standard for Torque values”

But context isn’t just data. It’s location, team skill, and timing. Sharp instructions adapt to what’s relevant—not everything you know, only what they need.

Examples (not detailed): Overhead Crane Maintenance

- Confirm all guards are in place before energizing. Isolate busbar section using local lockout SOP.

- Verify voltage is zero. Using a multimeter or voltage detector do not rely on gauge

- Inspect oil level via sight glass (oil level eye). Oil should be visible at the center mark. If oil is below the mark, top up following specification. Do not top up if there is evidence of leakage—report and investigate first.

- Check brake pad thickness at inspection port. Replace if below 6 mm. Follow brake pad replacement SOP 5.3.2

🧩 Standardize the Core, Flex the Rest

Templates help teams stay consistent. But rigid instructions break down in the field. Leave space for known variation.

For example, “Check brush wear with depth gauge. Replace if below 5 mm per SOP 4.2.1.” That protects standards, while trusting team awareness.Images can be added

Sharp instructions don’t lock the process—they guide it.

🔁 Make It Reusable, Not Repetitive

Sharp instructions often repeat across jobs. Don’t rewrite—modularize. Break tasks into reusable blocks: inspection, lubrication, start-up.

Give each block its own code, owner, and version. Then link tasks across jobs. On digital systems that a piece of cake, I remember the old days when we need to print everything and many times technicians are not willing to carry all these papers and field notes even wrapped in plastic are often lost or ruined.

This keeps work instructions clean, lean, and reliable—while building a smarter system underneath.

Table: Standard Wear Limits

| Component | Wear Limit (mm) | Reference SOP |

|---|---|---|

| Motor Brushes | 5 | SOP 4.2.1 |

| Brake Pads | 6 | SOP 5.3.2 |

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

Third: Sharpen, Reuse, and Evolve the Instruction Set

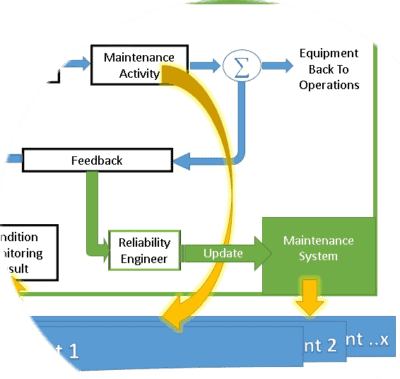

Sharp instructions aren’t static. They live, adapt, and improve. Reliability grows when we design for reuse, reduce mistakes, and build feedback into the system.

🔁 Design for Reuse

Don’t rewrite what already works. Break tasks into clear, modular blocks. Label and store them for future jobs.

This cuts repetition and boosts reliability. Teams recognize familiar steps faster. Mistakes drop when the format stays consistent.

Reusable instructions also speed up planning. One good instruction serves many use cases, from routine checks to complex overhauls.

✏️ Prevent Mistakes with Better Wording

Poor wording invites failure. Use simple, direct language. Avoid passive verbs. Eliminate double meanings.

Say: “Clean surface with lint-free cloth.”

Not: “Prepare the area appropriately.”

Clarity improves both quality and safety. Teams don’t need to guess. They just do.

🔄 Keep Instructions Alive

Treat instructions like living assets. Assign ownership. Set review intervals. Mark revision dates clearly.

Outdated steps create risk. Updated steps build trust. Updating isn’t a burden—it’s maintenance for the instruction itself.

Reliable Maintenance depends on reliable documents. That means they evolve with the work.

LOWEST-PRICE-24F-01M

LOWEST-PRICE-24F-01M

🗣️ Use Feedback to Refine

Technicians hold real-world insight. Make it easy for them to comment or flag unclear steps.

Feedback loops strengthen ownership. They also reveal where instructions fall short—or where they shine.

Improvement becomes culture, not correction. And every revision makes sharp instructions even sharper.

🔧 Final Thought: Make Sharp Instructions a Practice, Not Just a Principle

Sharp instructions do more than guide. They shape behavior, build trust, and protect reliability on every level. But sharp doesn’t mean cold or harsh. It means focused, clear, thoughtful, and role-specific.

We’ve explored how to strike that balance—using the right level of abstraction, writing with context, and structuring steps for clarity. We’ve seen how reuse, wording, and feedback all play a role. And we’ve seen how psychology and standards back this up: instructions should guide, not control.

When instructions evolve with the work and reflect the people doing it, they become more than documents—they become part of the system’s strength.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store