Advanced roadmap to take maintenance to the next level in 2024-2

With this guide, your maintenance system can continuously evolve as time goes on. It is the roadmap that we can rely on for 2024.

With this guide, your maintenance system can continuously evolve as time goes on. It is the roadmap that we can rely on for 2024.

By leveraging basic tools and free online digital resources, organizations can embark on a journey towards a more efficient and reliable maintenance framework. This will make the roadmap to take maintenance to the next level in 2024 real.

Simplicity of any process leads to agility of this same process. Eliminating or rejecting tasks that are not adding value to the maintenance process would free the precious time and effort of the maintenance team. Hence increasing its simplicity score. How?

What is reliability in life and maintenance? It is not only dependability

An intro to move forward to the next step in any of the maintenance management pillars and what you need to be aware of the grid that constructs this page of life.

Before you return to disengagement or to forget why you were doing this task, ask your self “Are you 100% sure?” Read how to maintain trust..

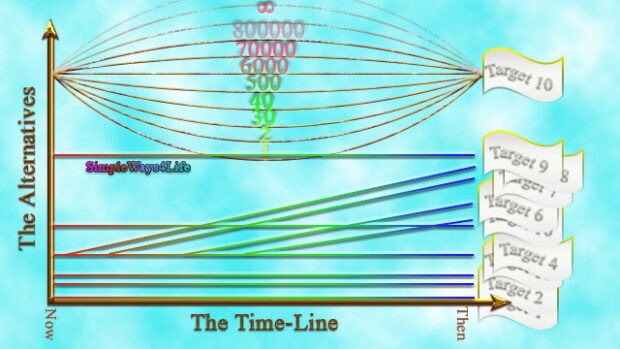

Shifting your timeline does not need a major modification, Small consistent steps will yield better and more sustainable results. The whole story and examples were covered in this article

This chat added some eye opening insights on the failure modes while exploring the failure levels and subsystem partitioning

In the this chat we shall demonstrate failure modes of some sample equipment and some guides to properly level your…

This chat draws a perception of the The Failure Mode, its importance and how to select useful ones.

Your team of maintainers and operators are the best source for the Failure Effect knowledge. Other resources carries only information.

Read to know the pros and cons of the first source that comes to mind for the knowledge of the Failure Effect. Is it information or knowledge?

Read in this chat some insights on the steps of collecting the Failure Effect (FE) of a specific Failure Mode (FM) on your way to apply RCM

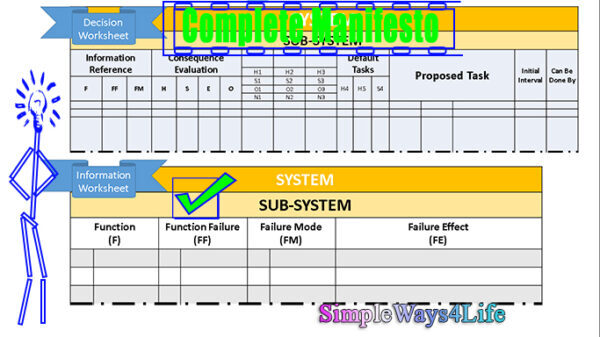

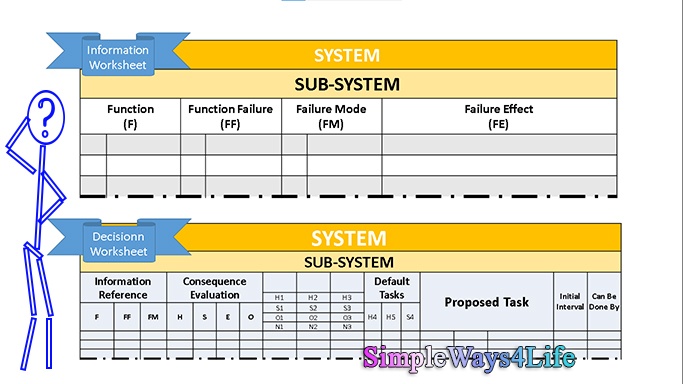

We shall demonstrate the main jargons used in the decision making sheet of the RCM (Reliability-Centered Maintenance). Those expressions are…

In order to have robust foundation about RCM, that’s a starting point to define the acronyms and Jargons specific to RCM Worksheets.

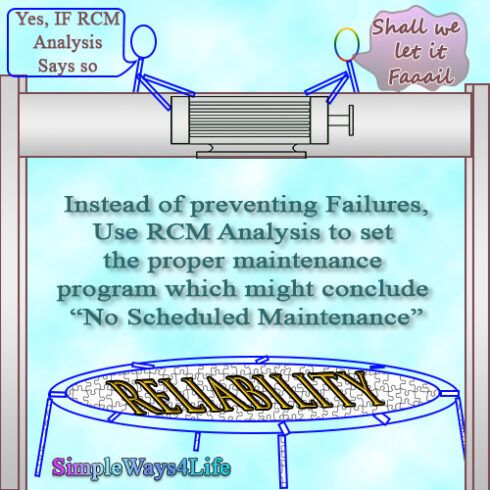

Proactivity sounds great but it must be rationalized using an RCM typical question “Do this maintenance activity worth doing?” Read more here

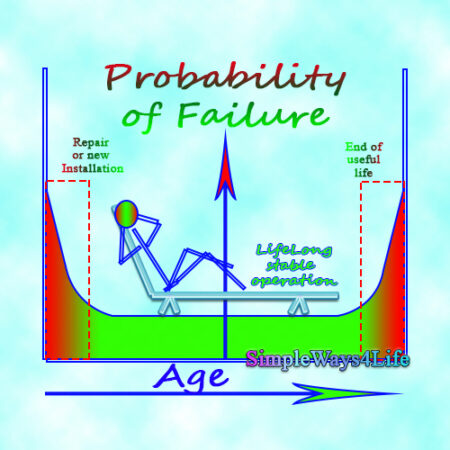

Trying to prevent the equipment from failing without analyzing it operation context, its capability and how it fails is a waste of time Reliability has the solution to this.

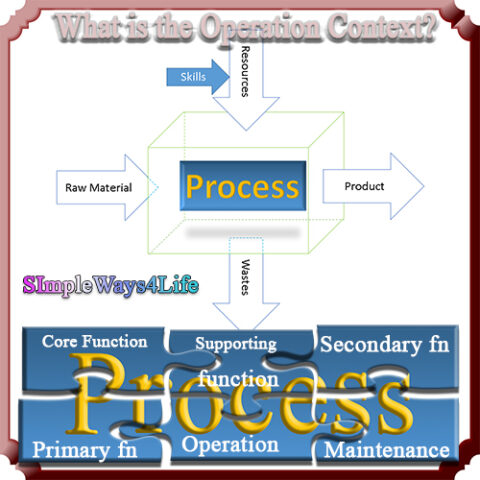

The reasons of many failures can be demystified when its operation context is clear and agreed upon. How operators and maintainers see it? it is clarified here in this chat.

We intend to make Reliability easy to understand and use. You will see the need of reliability as a framework for maintenance tasks selection and more. Even we shall relate it to its backgrounds in our daily life.