Maintenance Management 101 – First Things First – 1/2

There are Five steps and one illusion needed to put all the tasks in our mind in the correct order. Find more about them here…part1/2

There are Five steps and one illusion needed to put all the tasks in our mind in the correct order. Find more about them here…part1/2

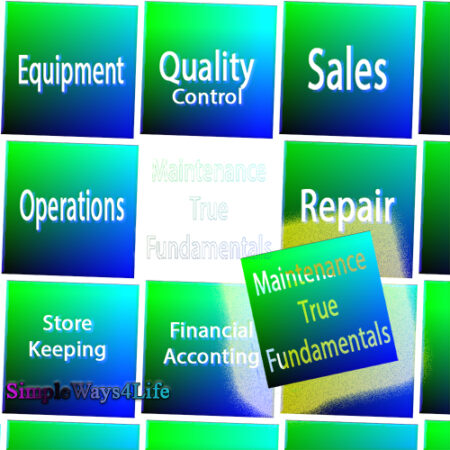

How to grip the maintenance benefits? Read here a simple approach to what is the missing milestone or piece of the maintenance puzzle.

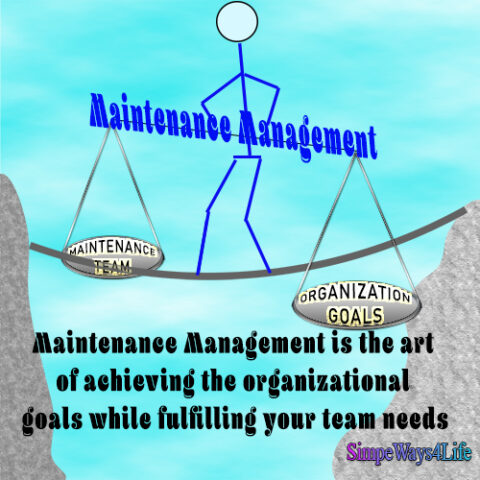

Why it is vital to be dynamic in your maintenance management? Why rigidity in controlling the maintenance team is not the best road?

We are back after a short vacation during October. We came back with an generous give back of 50min initial…

If all the business units are fulfilling their functional strategies but there is no profit, then they are not streamlined. More details inside.

There is a strategy behind every action we take in life or at work whether you are aware of it or not. Know here what a strategy is.

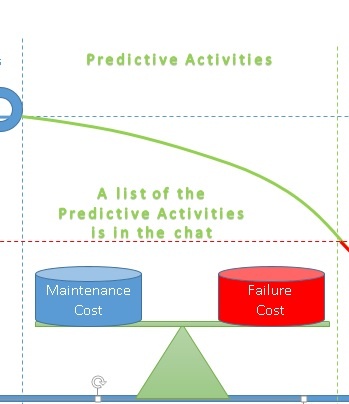

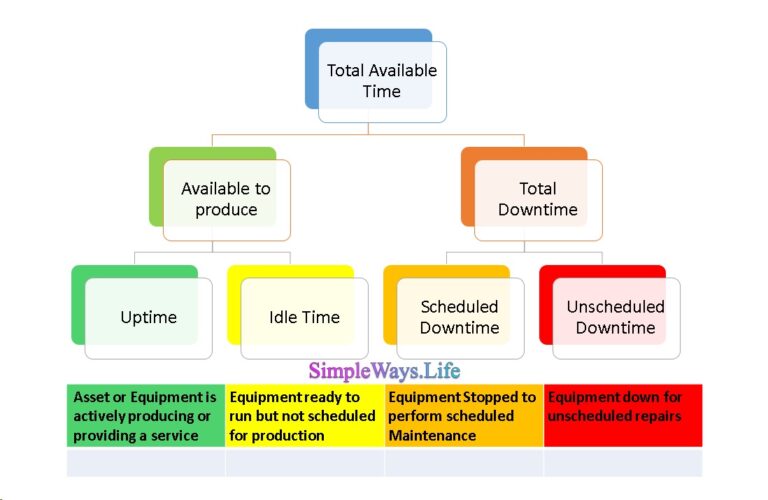

All Maintenance tasks targets maintaining the equipment acceptable performance. On the P-F curve you will know the three types of tasks.

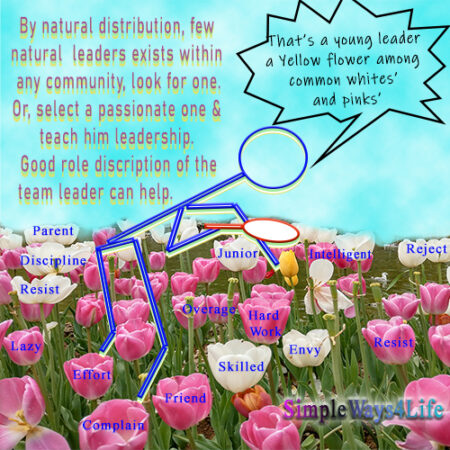

Maintenance is like life, you grow anyhow in each of them. You’d rather improve while growing. Maintenance can be improved in endless ways.

Maintenance System is not your boss or your enemy. It is your ally to do better easier jobs professionally. Why some people worship it?

Whenever you intend to have a maintenance system, it is easy to start one immediately and tune it as you go. Learn easy steps to do so.