Episode 2, A cheerful workplace, the importance of the light seeds

Do you want to take a break from this discomfort or to try something different? Follow up with us to plant your first seeds of light…

Do you want to take a break from this discomfort or to try something different? Follow up with us to plant your first seeds of light…

What brought us here was the quest for a cheerful workplace. We had embarked on a journey to create such a workplace, follow it up with us…

At the top of this chat we presented the top ten (10) things to prepare in the workplace to boost your team productivity.

Explor the different folds of the maintenance productivity for the maintenance subgroups and the maintenance process in general.

Productivity is a result of the collaboration between machines and workers. There is still a wide room for workers in every industry. Reality?!

This chat clarified the productivity calculation and the secret ingredient that will let you understand the “PRODUCTIVITY” results, read it..

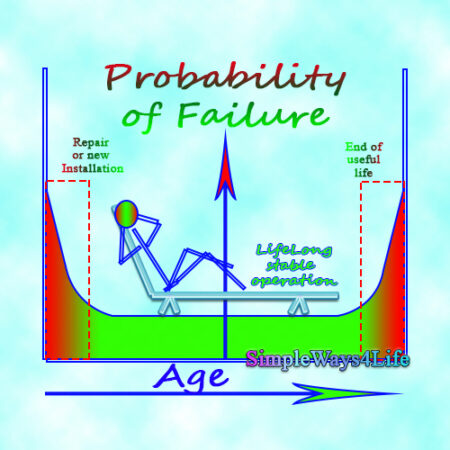

This chat added some eye opening insights on the failure modes while exploring the failure levels and subsystem partitioning

In the this chat we shall demonstrate failure modes of some sample equipment and some guides to properly level your…

This chat draws a perception of the The Failure Mode, its importance and how to select useful ones.

Your team of maintainers and operators are the best source for the Failure Effect knowledge. Other resources carries only information.

Read to know the pros and cons of the first source that comes to mind for the knowledge of the Failure Effect. Is it information or knowledge?

Read in this chat some insights on the steps of collecting the Failure Effect (FE) of a specific Failure Mode (FM) on your way to apply RCM

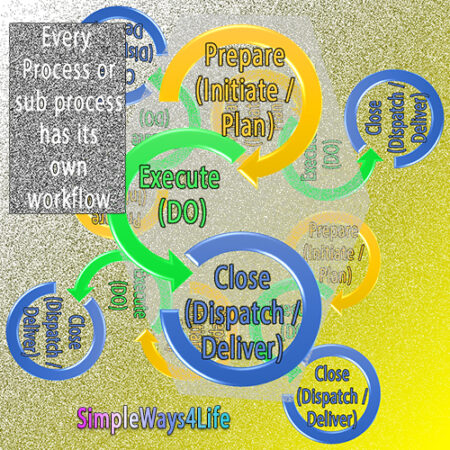

Why we need to carefully craft the workflow of any process in our life and work? What is the work flow? Where spontaneity fit in the equation?

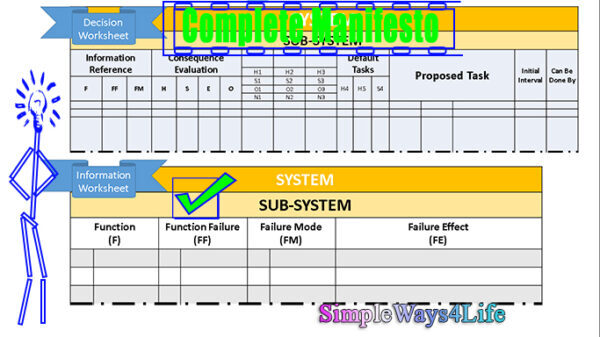

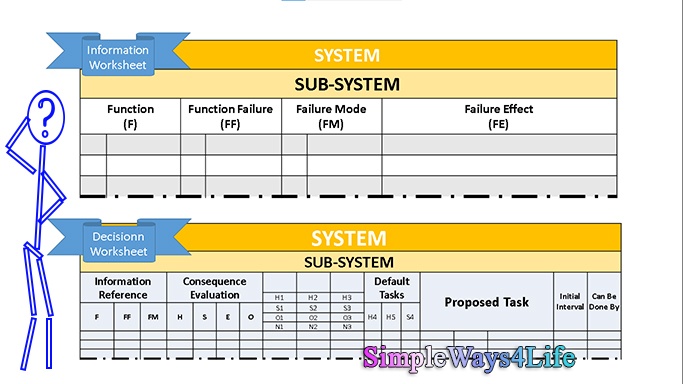

We shall demonstrate the main jargons used in the decision making sheet of the RCM (Reliability-Centered Maintenance). Those expressions are…

In order to have robust foundation about RCM, that’s a starting point to define the acronyms and Jargons specific to RCM Worksheets.

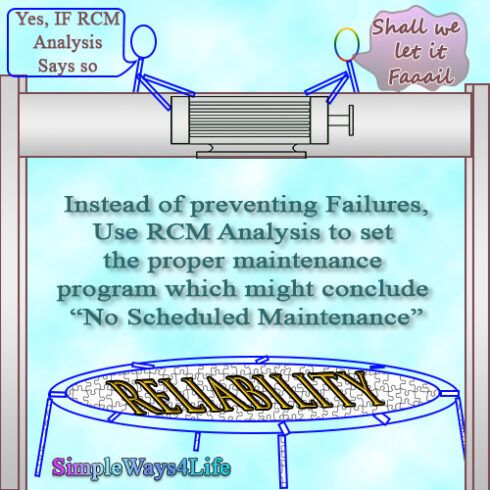

Proactivity sounds great but it must be rationalized using an RCM typical question “Do this maintenance activity worth doing?” Read more here

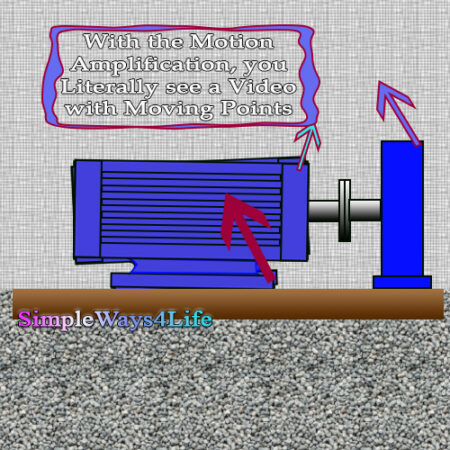

The Motion Amplification technology introduced in this chat carries its own style to grab the attention of the users. Read the details here.

Trying to prevent the equipment from failing without analyzing it operation context, its capability and how it fails is a waste of time Reliability has the solution to this.

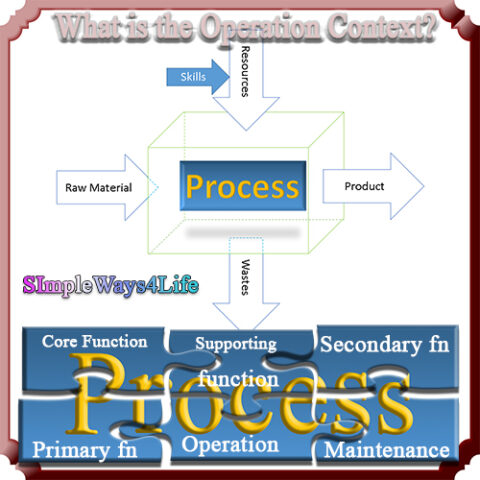

The reasons of many failures can be demystified when its operation context is clear and agreed upon. How operators and maintainers see it? it is clarified here in this chat.

We intend to make Reliability easy to understand and use. You will see the need of reliability as a framework for maintenance tasks selection and more. Even we shall relate it to its backgrounds in our daily life.