As we stand on the threshold of a new year, it’s not only an opportune time to reflect on the lessons learned from the past year but also to unbox new opportunities and cultivate innovative ideas. We will explore strategies for conducting a comprehensive roundup of the lessons learned in 2023 and provide insights into how to foster creativity and embrace innovative thinking in the upcoming year. Let’s start by welcoming the new

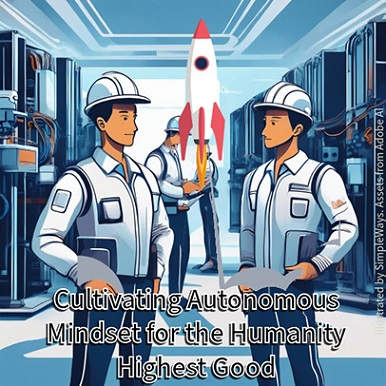

I. Strategies for Unboxing New Opportunities and Innovative Ideas in 2024:

1. Fostering a Culture of Innovation:

- Encourage Creative Thinking: Cultivate a culture that encourages employees to think creatively. Create platforms for idea sharing and recognize and reward innovative contributions. You can mix it with the quest for a cheerful workplace. You can embark on a journey to create such a workplace, follow it up with us in this article: The fantasy of a cheerful workplace

BESTPRICEENDS-11FEB

2. Cross-Functional Collaboration:

- Break Silos: Promote collaboration across different departments and teams. Cross-functional collaboration sparks diverse perspectives and can lead to innovative solutions. Have Integrity, be humble with others and avoid compromising the work needs let’s delve deep into the fact that we are one to see how to do it? Episode 8, A cheerful workplace, we are one divided into bodies

3. Continuous Learning and Development:

- Invest in team Growth – Including YOU- : Prioritize continuous learning and development opportunities because it helps in unboxing new opportunities. An educated and skilled workforce is more likely to generate innovative ideas. Your next higher level is just few steps away. How to move forward on the timeline to prepare for it? It is all here with practical steps How to take Maintenance to the next level?

4. Embracing Diversity and Inclusion:

- Diverse Perspectives: Embrace diversity and inclusion. A diverse workforce brings together individuals with different backgrounds, experiences, and perspectives, fostering creativity and innovation. Diversity of the technical skills and the skill levels among the team is driven through a matrix of factors affecting the skills building and levelling up. More elaboration was in this article: The Future of Maintenance – Part 14 – Team Diversity

5. Technology Integration:

- Leverage Emerging Technologies: Stay informed about emerging technologies relevant to your industry. Explore how technologies like artificial intelligence, blockchain, or augmented reality can be integrated into your operations because it helps in unboxing new opportunities. 11 Steps to introduce a new Technology to the team

BESTPRICEENDS-11FEB

BESTPRICEENDS-11FEB

6. Customer-Centric Approach:

- Listen to Customer Needs: Prioritize a customer-centric approach. Actively listen to customer feedback and use it to tailor products or services to better meet their needs and expectations. We need to start by defining our customers. For maintenance process to be Agile from the perspective of its customers and stakeholders we need to understand stakeholders needs. Frequent communication with stakeholders leads to Agility – Part 4

7. Agile and Adaptive Strategies:

- Agile Methodologies: Adopt agile methodologies in business processes. The ability to adapt quickly to changing circumstances is crucial for fostering innovation. Maintenance highest priority is to satisfy the customer through early and continuous delivery of valuable Maintenance. Which now perfectly describes the world class maintenance and makes maintenance Agile. Agile maintenance helps in unboxing new opportunities. Can Maintenance be Agile?-Part2

8. Environmental and Social Responsibility:

- Sustainable Practices: Integrate environmental and social responsibility into business practices. Consumers increasingly favor companies with a commitment to sustainability, and this can open doors to new markets and opportunities. By reading this article you will know how Maintenance and the environment are linked in maintaining the environmental compliance of the organization This role is ethical in the first place: Maintenance and the Environment

9. Strategic Partnerships:

- Collaborate with Partners: Explore strategic partnerships with other organizations. Partnerships can provide access to new markets, technologies, and ideas and, helps in unboxing new opportunities.. You can use any of SimpleWays services through this link Store for Maintenance and Digital Services

BESTPRICEENDS-11FEB

10. Scenario Planning:

- Anticipate Future Trends: Engage in scenario planning to anticipate future trends and challenges. Being proactive in understanding potential scenarios helps in developing innovative strategies.

11. Experimentation and Risk-Taking:

- Encourage Risk-Taking: Create an environment where calculated risks are encouraged. Innovation often involves stepping into uncharted territory, and a willingness to experiment is key.

II. A Roundup of Lessons Learned in 2023:

1. Reflection on Achievements and Challenges:

- Look Back to Move Forward: Begin the roundup process by reflecting on the achievements and challenges faced in 2023. Identify key milestones, successful projects, and areas that presented difficulties. Maintenance needs a starting block to boost its performance & preload the maintainers mental and physical muscles with the necessary tools. Does Maintenance need a starting block?

BESTPRICEENDS-11FEB

2. Assessing Goals and Objectives:

- Evaluate Goal Attainment: Review the goals and objectives set for 2023. Assess which goals were achieved, which ones fell short, and the reasons behind both outcomes. You can use statistical tools to gain the needed insights. You can build the complete maintenance process around data visualization. There is no activity in maintenance that won’t get better by adding data visualization. it’s essential to choose the right types of charts and graphs based on the specific goals and characteristics of the data. How to build maintenance around Data Visualization? -3

3. Stakeholder Feedback:

- Engage with Stakeholders: Collect feedback from stakeholders, including employees, clients, and partners. Their perspectives provide valuable insights into various aspects of your business.

4. Performance Metrics and KPIs:

- Analyze Metrics: Dive into performance metrics and Key Performance Indicators (KPIs). Identify trends, patterns, and areas that require improvement.

5. Adaptation to Market Trends:

- Market Trends Analysis: Assess how well your organization adapted to market trends. Recognize areas where staying ahead of the curve proved beneficial and areas that may require a more proactive approach in the future. Historically maintenance evolves as industry evolves. With every Industrial Revolution, Maintenance tools and strategies grow to provide the needed service for this industrial era. Now what shall we do with the Augmented reality and other technologies Industry 4.0 introduce in the production environment??! The future of Maintenance – Part 3-Maintenance follows the Industry

BESTPRICEENDS-11FEB

BESTPRICEENDS-11FEB

6. Reviewing Risk Management:

- Risk Assessment: Evaluate the effectiveness of your risk management strategies. Analyze how well your organization responded to unexpected challenges and identify opportunities for improvement.

7. Employee Development and Satisfaction:

- Employee Feedback: Gather feedback from employees regarding their experiences and job satisfaction. Identify areas where professional development programs were successful and areas that need enhancement.

8. Financial Performance:

- Financial Review: Conduct a thorough review of financial performance. Understand revenue streams, cost structures, and areas for financial optimization. But we need to start from the basics. We can start from how maintenance of partial failures or their prevention saves a lot of cost. Let’s see some practical industrial examples that clarify how maintenance of partial failures will enforce Maintenance added value. More on the importance of Maintenance Added Value

9. Customer Satisfaction:

- Customer Surveys: Review customer satisfaction surveys and feedback. Understand customer needs, expectations, and areas where the organization excelled or fell short.

BESTPRICEENDS-11FEB

10. Technology Utilization:

- Technology Assessment: Evaluate the effectiveness of technology implementations. Identify successful technological advancements and areas where improvements or updates are necessary because it helps in unboxing new opportunities..

Conclusion:

In conclusion, the transition from 2023 to 2024 offers an invaluable opportunity for organizations to not only conduct a comprehensive roundup of lessons learned but also to unbox new opportunities and foster innovative thinking.

If you feel you need help with any of these ideas we discussed, request a Management Consultancy or Coaching Services From our Store