The small skills that count

We can’t link our innate projects skills to where they fit technically if we overlooked the professional terminologies of the skills we excel

We can’t link our innate projects skills to where they fit technically if we overlooked the professional terminologies of the skills we excel

Do you have a couple of good skills and a few that you think you need to develop? Do you…

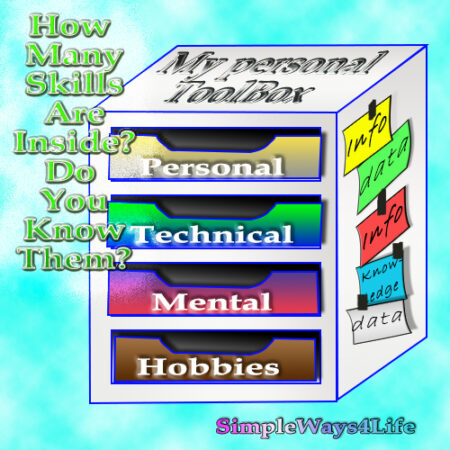

The simple conscious awareness of tools available at our reach and the know how to use them opens the door for infinite possibilities, know your tools here

Have Integrity, be humble with others and avoid compromising the work needs let’s delve deep into the fact that we are one to see how to do it?

To change your perceptions and expectations to expect that the good is what always to come in your workplace follow those steps.

The 15 questions provided in this chat will help you see your perceptions about work & their sources . Once seen clearer, you can recolor it

Know how the small changes that lasts create more profound changes into the workplace culture. Let’s demystify it with some life examples…

There are formal steps to the change management. But enforcing cheerfulness in the workplace might be worse than its absence, Why?? Read it

A cheerful workplace is a workplace that is cheerful on the route to your targets even if you choose to climb a mountain to reach them.

Do you want to take a break from this discomfort or to try something different? Follow up with us to plant your first seeds of light…